Harvey Table Saw: 5 Reasons Pros Buy

What makes the Harvey table saw a top pick for pros? Is it the Big Eye rip fence, the Alpha series build, or the cast-iron parts that keep cuts true? This post lists five clear reasons pros buy Harvey saws. Expect short notes on precision, durability, miter accuracy, horsepower, and useful accessories.

Table of Contents

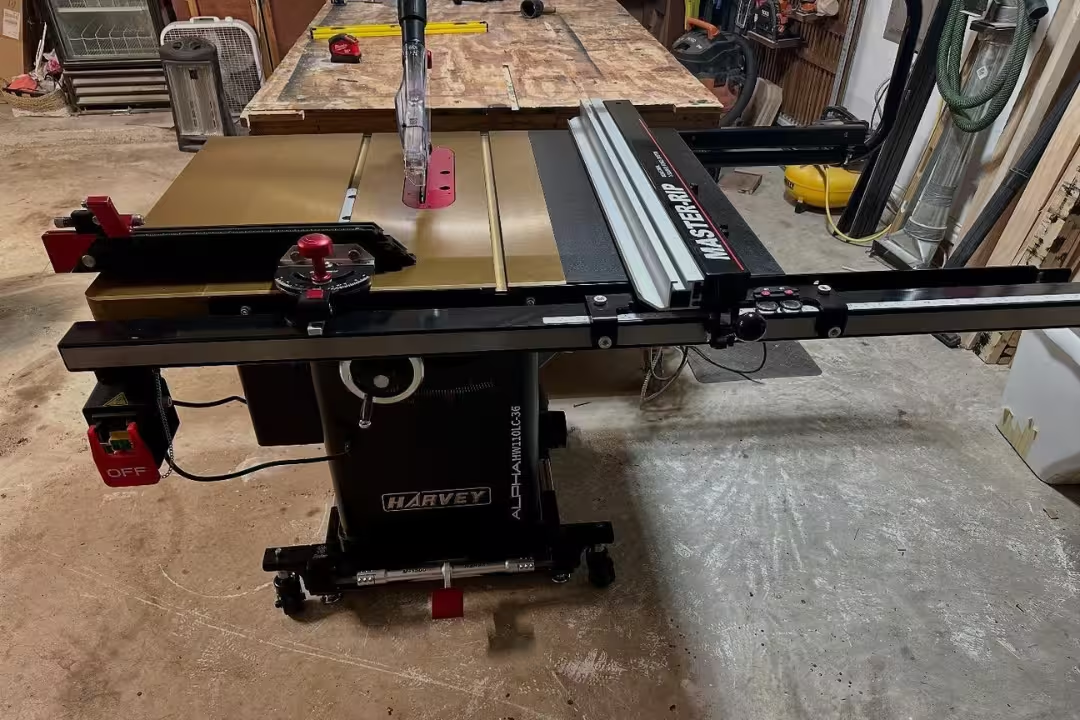

A Harvey table saw sits in the “premium cabinet saw” lane, with a focus on fence accuracy, corrosion resistance, and repeatable setups. This guide breaks down the Alpha lineup, key specs, and the real-world reasons many shops shortlist Harvey for daily production work.

Harvey table saw at a glance

If you’re comparing cabinet saws, start with three items: motor class, rip capacity, and the fence and miter system you’ll use every day. Harvey’s Alpha series is built around nickel-plated cast iron, cabinet-mounted trunnions, and pro-grade accessories that reduce setup time between cuts.

Alpha series models

The Alpha lineup centers on models like the HW110LC-36Pro (2HP) and HW110TC-36Pro/52Pro (3HP), both positioned as cabinet saws with pro fences and miter systems. For model-level details and current configurations, use the official product pages for the Alpha HW110TC-36Pro/52Pro.

Table, blade, arbor specs

Most North American Alpha builds run a 10-inch (254mm max) blade with a 5/8-inch arbor, which keeps blade shopping simple if you already stock 10-inch combos and rippers. Harvey also ships a general-purpose DESTROYER blade on many packages, so you can test the saw’s baseline cut quality before swapping to your preferred brand; confirm blade and arbor specs in the Harvey Alpha series blade and arbor specifications.

PRO vs standard upgrades

In a typical harvey table saw review, the PRO trim matters because it packages the features that affect accuracy and “daily feel”: the Big Eye Rip Fence, upgraded coatings, and top-shelf included blade in many bundles. Before you decide, compare the PRO vs standard matrix so you know what you’re paying for versus what you can add later; start at the Harvey Alpha series comparison chart.

| Spec / feature | What it changes in the shop |

|---|---|

| 10-inch blade, 5/8-inch arbor | Easy blade swaps and broad blade availability |

| 2HP vs 3HP motor | Feed rate on thick stock, long rips, and production pace |

| 36-inch vs 52-inch rip | Handling sheet goods without breaking down first; panel workflow |

| PRO fence + miter package | Less re-measuring, fewer test cuts, repeatable accuracy |

Big Eye Rip Fence precision

The Big Eye Rip Fence is the headline feature people cite when they buy a Harvey table saw for cabinet work. It’s built to move smoothly and lock predictably, so you spend less time “sneaking up” on a dimension and more time cutting to a known setting.

Dual-axis roller rail

Instead of sliding on friction, the fence rides on a dual-axis system with multiple rollers on hardened steel rods, which helps it glide without stick-slip. Harvey states about 0.15mm accuracy across the length, which is the kind of spec that shows up as fewer “one more pass” rips when you’re fitting face frames or shelves (see details on the Alpha HW110LC-36Pro product page).

High/low fence plates

High/low plates let you choose more face support for tall rips or a lower profile when you want better control over thinner stock. In practice, that fence versatility helps with tasks like cutting veneered panels (less tipping) and ripping thin strips (better hand placement and push-stick control).

Rip capacity options

Pick 36-inch class if you mostly rip solid wood and pre-break sheet goods, or 52-inch class if you process full panels on the saw. Match rip capacity to your material flow, then build outfeed and side support around it so the fence accuracy you paid for shows up in the final parts.

If you want a compact alternative to compare features and footprint, here’s a quick product reference:

Nickel-plated durability

Nickel plating is one of the most practical reasons people stick with this saw long term. It fights rust and wear in humid shops, so your table stays slick and your settings stay consistent, even when you’re processing rough stock all week.

Cast-iron rust resistance

Harvey uses nickel-plated cast iron with a stated hardness range around 500–700 HV, which supports corrosion resistance and surface durability. That matters if your shop swings between seasons or you run dust collection that pulls moist air, since rust pits can telegraph into cut quality over time.

Worm-gear trunnion build

The worm-gear trunnion design aims for smooth elevation and bevel moves under load, so you can dial in height without “overshooting” and coming back. Keep the mechanism clean, check belt tension on schedule, and you’ll get predictable adjustments that hold during long runs.

Long-term shop reliability

For long ownership, plan a simple routine: wipe the top after glue-ups, use a non-silicone protectant, and track alignment every few months with a dial indicator. That small maintenance loop protects your flat reference surface and reduces the “mystery drift” that wastes hours on install days.

COMPASS MG-36Pro miter accuracy

A good fence makes straight rips easy; a good miter system makes joinery repeatable. The COMPASS MG-36Pro is built for angle confidence, so a “45” on the gauge actually behaves like a 45 when parts meet on the bench.

Positive angle stops

Positive stops help you land on common angles quickly, which is a big deal in batch work like cabinet rails or face-frame parts. Harvey cites 0.1-degree accuracy, and the real payoff is fewer test cuts when you jump between 90s, 45s, and repeat angles.

Vernier scale options

With vernier-style reading, you can dial a specific angle and come back to it later without guessing. If you do segmented work, miters for trim, or furniture parts that must close tight, that fine control saves sanding and clamp wrestling.

Repeatable crosscuts

Repeatability improves when the miter bar fits the slot without slop and the fence face stays square under pressure. Pair the gauge with a stop block system and a sharp combo blade, and you’ll get batch consistency that feels closer to a small slider for many cabinet tasks.

Pro power and capacity

Power and capacity decide what your saw feels like on hardwood and how you break down sheet goods. The Harvey Alpha table saw lineup covers both “serious hobby” and “daily pro” needs, mainly through the 2HP vs 3HP split and 36-inch vs 52-inch rips.

2HP vs 3HP motors

A 2HP cabinet saw can thrive in many garages, especially if you use sharp blades and sensible feed rates, while 3HP helps maintain speed in thick rips and long sessions. If your workflow includes 8/4 hardwood or frequent glue-line rips, 3HP headroom pays off in fewer burn marks and less fussing.

30-inch vs 52-inch rip

A 30–36-inch class rip is often enough if you already rough-cut panels with a track saw, while 52-inch shines when the table saw is your main panel tool. If you’re still deciding your shop’s “panel plan,” review our best table saw guide to weigh cabinet saws against jobsite and hybrid styles.

Premium-brand value comparison

Comparing value means matching total capability, not brand name: fence feel, table stability, dust control, and how often you re-check calibration. Some premium saws earn their price in resale and familiarity, yet many buyers put Harvey on the shortlist for pro features at a lower cost than legacy “big iron” options; see perspective in Great Saws from Harvey.

To compare capability across different saw classes, review these popular alternatives:

Delta 3 HP UniSaw

- Robust 3 HP motor delivers professional cutting power and torque

- Compatible with 10 inch blades for versatile woodworking tasks

- Includes 52 inch Biesemeyer fence for large rip capacity and stability

- Heavy-duty construction built for shop durability and reduced vibration

- Precision components provide repeatable, accurate performance

SKIL 10 inch Jobsite Table Saw

- Powerful 15 amp motor handles ripping and tougher cuts

- Folding stand makes transport and storage simple

- Rack and pinion fence ensures fast, accurate adjustments

- Compact design built for jobsite mobility and setup speed

- Onboard storage for accessories keeps everything organized

Safety and dust control

Safety features don’t replace good technique, yet they do reduce exposure during repetitive work. Harvey focuses on a magnetic switch, guarding, and dust capture that’s meant to stay in use instead of coming off after day one.

Magnetic safety switch

A magnetic switch helps prevent an unexpected restart after a power blip, which matters in shared circuits and small shops. Add a large paddle-style shutoff near knee height and you get faster stops during bind-ups or offcuts that shift.

Blade guard and dust shroud

Dust control improves when the shroud captures chips close to the blade and the guard doesn’t block your workflow. If you’re still building your collection system, our router table guide includes practical dust-hose and workflow ideas that transfer well to table saw stations.

Kickback-reduction design

Kickback risk drops when stock stays tight to the fence and table, the blade stays sharp, and you use hold-downs for narrow work. Add featherboards and a split/guard system to keep a controlled feed, especially when ripping long hardwood where internal stress can pinch the kerf.

These add-ons can help you build safer, cleaner table-saw habits:

One-Way Roller Featherboard

- Roller design holds workpiece firmly against the fence for cleaner cuts

- Reduces tear-out and improves surface finish

- Quick and secure mounting to table saw and router tables

- Durable construction for long-term workshop use

- Enhances safety and repeatability on repetitive cuts

Hedgehog Featherboard

- Quickly secures to fence for fast setup and repeatable cuts

- Improves cut accuracy by keeping stock tight to the fence

- Reduces kickback and increases operator safety

- Low-profile design minimizes interference with workpieces

- Durable teeth provide consistent grip without marring wood

Paddle Power Switch 110 to 120V

- Heavy-duty paddle for easy on and off control even with gloves on

- Includes extension cord and integrated receptacle for safe hookups

- Compatible with table saws, router tables, and drill presses

- Rugged construction designed for frequent shop use

- Simple installation upgrades safety and emergency stop response

SURAIELEC Auto Vacuum Switch

- Auto, On, and Off modes let tools control dust collection automatically

- Built-in delay shutoff extends vacuum run to clear hoses

- Supports 125V 15 amp devices up to 1875 watts for wide compatibility

- Simple plug and play setup for shop vacs and dust collectors

- Keeps workspace cleaner and improves dust management safety

Accuracy arrives faster when your fence, miter gauge, and dust collection stay installed and dialed—then your “setup” becomes a quick check, not a rebuild.

Shop setup principle

Harvey table saw accessories that elevate setups

The right harvey table saw accessories do two jobs: they expand what the saw can do and they cut setup time per operation. If you treat accessories like part of a system (saw + work support + measurement), you’ll get cleaner results with fewer retries.

COMPASS Router Table add-on

A router-table add-on makes sense when you want one central workstation for grooves, edge profiles, and joinery. Harvey promotes fine tuning down to 0.001-inch on some router-table components, which is useful for repeat dado depth and snug-fitting joinery; get the official accessory range from Harvey table saw collection.

Industrial Slider attachment

A slider attachment helps when crosscutting wide panels or squaring cabinet parts without wrestling a bulky crosscut sled. If you often break down sheet goods, a slider improves panel control and reduces the chances of twisting mid-cut.

Tri-axis overarm guard

An overarm guard earns its keep when it stays easy to position and doesn’t fight your fence setup. The tri-axis style gives more placement options, which boosts real-world guard usage and can improve top-side dust pickup during long rip sessions.

Calibration blocks and jigs

Calibration tools speed up alignment checks for blade-to-slot, fence parallelism, and miter settings. A basic kit—thin rip jig, dial indicator, and setup blocks—can reduce your “is it the saw or the wood?” guessing and keep tolerances stable across projects.

- Check blade-to-miter-slot alignment with a dial indicator before you chase fence issues.

- Use setup blocks for repeatable blade height and dado stack settings.

- Add a thin-rip jig for consistent strips without pinching between blade and fence.

Here are popular calibration-friendly add-ons to compare:

Saker Thin Rip Jig

- Precision jig for making narrow, repetitive strip cuts with ease

- Fits 3/4 inch by 3/8 inch T slots for broad compatibility

- Thin profile reduces material waste and improves cut control

- Sturdy build for consistent, repeatable setups

- Quick clamp and release speeds up production work

Precision Dial Indicator Gauge

- High accuracy to 0.01 millimeter for fine calibration work

- Designed to fit 3/4 inch T slots and common U slots on saws and tables

- Easy to mount and adjust for quick setup checks

- Ideal for aligning blades, fences, and machinery components

- Durable build ensures repeatable measurements over time

15-Piece Setup Blocks Gauge Set

- Set of 15 precision aluminum bars for quick machine setups

- Laser engraved size markings for fast and accurate selection

- Ideal for router, table saw, and other woodworking setups

- Compact organization makes storage and transport simple

- Improves setup speed and repeatability for consistent results

FAQs

Are Harvey Table Saws Any Good?

Yes, Harvey table saws are generally solid for hobbyists and light professional use.

They usually offer good build quality, accurate fences, and value-priced motors that suit woodworking projects and garage shops. For best results, match the model to your cut capacity, accuracy needs, and safety features, and read owner reviews and spec sheets before buying.

Where Are Harvey Table Saws Made?

Manufacturing locations can vary by model and production run.

Check the saw’s serial plate, packing slip, or the manufacturer’s website for the exact country of origin, as components or final assembly may be handled in different locations. If origin affects warranties or parts, contact the seller or Harvey customer support for confirmation.

Where To Buy Harvey Table Saw?

You can buy Harvey table saws from authorized dealers, specialty woodworking stores, and online retailers.

Compare prices, confirm warranty coverage, and check dealer support for setup and service. Consider buying locally if you want in-person inspection or faster service; used saws may appear on classified sites at lower prices but verify condition and safety features first.

How Do I Troubleshoot Motor, Arbor Or Electrical Issues On A Harvey Table Saw?

Start by turning off power and performing basic safety checks and visual inspections.

Unplug the saw, check the breaker and power cord, inspect motor brushes, switch, and arbor for visible damage, and make sure the blade rotates freely by hand. If problems persist, use a multimeter to check supply voltage and continuity per the manual and contact a qualified electrician or service technician for motor or complex electrical repairs.