JessEm Router Lift Guide: Rout-R-Lift II vs Mast-R-Lift II

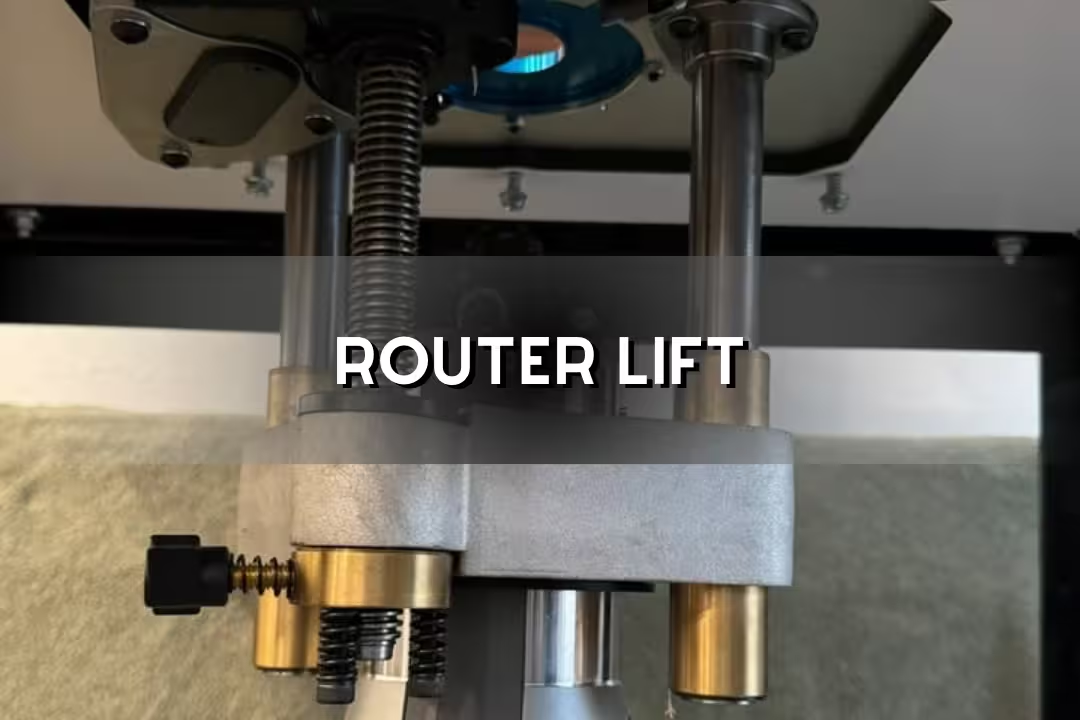

A jessem router lift is a router-table mechanism that raises and lowers a router motor from above the table for repeatable bit height and safer bit changes. In practice, it replaces under-table wrenching with a crank-and-lock system that’s easier to dial in for joinery and profiling.

Table of Contents

If you’re comparing models, “jessem router lift 2” is common shorthand for JessEm’s “II” lineup (like Rout-R-Lift II and Mast-R-Lift II), which share the same core idea: smooth lift travel, above-table control, and a positive lock so the bit height doesn’t creep mid-cut.

Jessem router lift overview

What it does

A lift holds your router motor in a carriage and moves it with a threaded screw so you can set bit height from the top of the table. The big difference you feel right away is control: the crank turns with steady resistance, and you can “sneak up” on a fit instead of bumping a router base and overshooting.

Above-table operation matters most when you’re doing repeat passes—like raising a panel bit in three steps—because you stop breaking your stance to grope under the table. That translates into fewer mistakes like forgetting to re-lock, or raising the bit while your stock is still pinned against the fence.

One real constraint: a lift doesn’t fix a flexy table. If the tabletop sags or the insert opening isn’t supported, you’ll still see chatter, burned edges, and height drift that feels like “the lift is slipping” when it’s actually the table moving.

Key specs snapshot

Most JessEm lifts you’ll see compared in listings share the same practical spec targets: a plate around 9-1/4″ x 11-3/4″, enough vertical travel for common bits, and a fine-pitch screw system that lets you dial micro adjustments. Those are the specs that show up in SERP snippets and drive compatibility with many router tables.

| Spec | What it means in the shop |

|---|---|

| Plate size (common) | A standard opening makes drop-in installs easier on many pre-cut tops. |

| Vertical travel (typical range) | More travel helps with tall bit setups and bit changes above the table. |

| Fine screw drive (often 16 TPI) | Small crank inputs create predictable height changes you can repeat. |

| Cam-lock | Stops height creep during heavy cuts like raised panels. |

| Insert ring system | Right-size openings improve workpiece support and chip control. |

For a spec reference that matches what many shoppers compare (including the common 9-1/4″ x 11-3/4″ plate format), I cross-check retailer listings like TayTools Rout-R-Lift II listing before committing to a top cutout.

Jessem router lift 2 meaning

People type jessem router lift 2 when they mean the “II” generation: Rout-R-Lift II, Mast-R-Lift II, and bundles built around those plates. In day-to-day use, the “II” label matters because the ecosystem—Tab-Loc rings, plate sizes, and above-table locking—stays consistent across many setups, so upgrades don’t force a full rebuild.

A common beginner mistake is assuming “2” means it fits “version 2” of a router table. Fit depends on plate footprint, corner radius, and whether your table uses leveling screws or a direct rabbet ledge, not the name printed on the box.

Key features that matter

Precision screw drive

JessEm lifts use a fine-pitch direct-drive screw, which is why the crank feels smooth instead of “poppy.” In real cuts, that shows up when you’re flushing edge banding or dialing tenon shoulders: you can feel the resistance build and stop exactly where the bit kisses your setup block.

Watch out for packed dust in the carriage area. Fine screws don’t like gritty chips; they start to feel crunchy and you’ll see inconsistent movement. My workaround is simple: blow out the cavity, then add a tiny amount of dry lube where chips won’t turn it into paste.

Cam-lock stability

The quarter-turn cam-lock is what keeps height from drifting when you hog material with a big bit. If you’ve ever heard the pitch change mid-pass and then noticed the profile looks “fatter,” that’s height creep—locking eliminates that failure mode.

Don’t over-torque the lock. It’s tempting to muscle it, but excessive force can make the lock feel sticky and encourages people to leave it partially engaged. A better habit is to set height, tap the lock firmly, then do a quick test cut in scrap to confirm nothing moved.

Bearing smoothness

Good lifts feel like turning a well-made vise: steady drag, no gritty spots, and no wobble when the motor is hanging at mid travel. JessEm’s use of sealed bearings matters because they keep motion consistent under load, especially with heavier 3.5″ motors where cheap lifts start to bind.

If your lift suddenly gets stiff, don’t assume the bearings failed first. The most common issue I see is a router motor clamp that’s slightly cocked, so the carriage rubs. Loosen, re-seat the motor so the clamp blocks pull evenly, then re-tighten in small alternating turns.

Above-table changes

Above-table bit changes are the feature you notice every session. Your hands stay where you can see them, and you’re not scraping knuckles on the cabinet floor. The sensory giveaway is simple: instead of the hollow clank of wrenches under the table, you hear the clean click of the spindle lock and feel the bit release without fighting gravity.

One risk: people assume “above-table change” means any bit, any collet, any table opening. Large panel raisers still need clearance through the insert ring and plate opening, and some routers need the motor raised high enough that the collet sits above the plate. Verify this with the biggest bit you own before a deadline build.

Jessem router lift models compared

Rout-R-Lift II

The Rout-R-Lift II is the sweet spot when you run a known 3.5″ motor and want JessEm’s core feel—smooth crank, fine control, and a positive lock—without paying for universal clamping. It’s also the model many shoppers mean when they type jessem router lift 2 and expect the “II” experience without extra accessories.

Where it can bite beginners: if your motor is even slightly outside spec, the fit won’t “sort of work.” A motor that measures a hair over 3.5″ can clamp unevenly and cause a tiny tilt that shows up as tapered joinery.

Rout-R-Lift II for 3.5 inch Motors

- Precision height adjustment for accurate cuts

- Designed for 3.5 inch diameter router motors

- Allows above table bit changes for quick swaps

- Heavy duty construction for long term stability

- Simple install and smooth operation

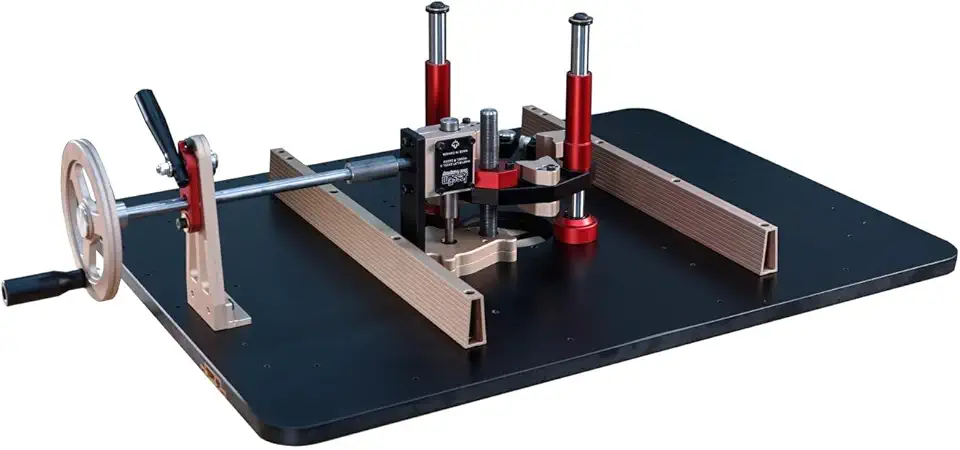

Mast-R-Lift II

Mast-R-Lift II is the pick when you want universal clamping across multiple routers or you plan to upgrade motors later. In a busy shop, that flexibility saves real time: I can swap motors for a dedicated bit setup, then come back to a known height with fewer re-dials.

Its trade-off is that universal systems demand more careful setup. If you rush the clamp block positioning, you’ll feel a slight “tick” at one point in travel. Resetting the clamps so they pull evenly fixes it, but it’s a step fixed-diameter lifts don’t need.

For official specs and included parts (like rings and hardware that vary by bundle), I refer to JessEm Mast-R-Lift II before buying a plate that’s meant to drop into an existing top.

Mast-R-Lift II with Top Plate and Ring Kit

- Smooth, reliable lift mechanism for fine tuning bit height

- Includes top plate plus 10 piece insert ring kit and caddy

- Quick ring changes to match bit diameters

- Rugged build for consistent table performance

- Easy mounting and compatibility with common router plates

Rout-R-Lift Prestige

The Prestige is the right direction if you’re committed to a plunge router in the table. Instead of clamping a motor can, it mounts the router base pattern in a way that works with certain plunge platforms that otherwise fight fixed-clamp lifts.

Most mistakes here come from mixing concepts: people buy Prestige expecting it to behave like a 3.5″ motor lift. If your router isn’t on the supported list, you can end up with a pattern mismatch that’s unsafe or impossible to center accurately.

For the supported plunge-router list and the ring sizes that ship with it, I cross-check Rout-R-Lift Prestige for plunge-based routers before purchasing.

Rout-R-Lift 3.5XT

The 3.5XT targets users who like the dedicated 3.5″ motor approach but want the newest refinement in feel and access. If your workflow is lots of repeatable height tweaks—pattern bits, cope-and-stick sets, and flush trimming—the smoother travel is something you feel through your fingertips, especially during micro moves.

One practical caution: newer variants can have small ecosystem differences (ring styles, included hardware, plate marking). Double-check what comes in the box so you don’t get stuck mid-install without a ring wrench or the leveling hardware you assumed was included.

Rout-R-Lift II Bundle with 10 Ring Kit

- Precision above table bit adjustment for safer changes

- Bundle includes Rout-R-Lift II and 10 piece insert ring kit with caddy

- Wide range of insert sizes for better bit support

- Robust construction for stable routing

- Easy to install and integrate on most tables

Router compatibility and fit

3.5-inch motor list

Dedicated 3.5″ lifts are happiest with common fixed-base motor cans like Porter-Cable 690/890, DeWalt 610/616/618, and Bosch 1617/1618. The win is a tight clamp with minimal fiddling, which usually translates to less chance of the motor shifting when you do aggressive edge profiling.

A quiet gotcha is rebrands and near-matches. Two routers can look identical but measure differently at the clamp area because of rubber grips, labels, or cast ridges. Measure the actual clamping surface, not the widest part of the housing.

Universal clamp fit

Universal clamp systems (like Mast-R-Lift II) shine if you own multiple routers or plan to switch later. In real use, it’s less about “fits 18 routers” and more about whether the clamps can grab a clean cylinder without riding on bumps, vents, or taper.

Clamping mistakes show up as vibration before they show up as slippage. If the cut sounds harsher and the table “buzzes” through your palms, stop and re-seat the motor. Slight misalignment can also push the bit off-center in the insert ring opening, which increases burning and chip recut.

Plunge-router fit

Plunge routers can work in a table, but some models fight you with spring tension, awkward locks, and base designs that don’t translate well to above-table bit changes. A plunge-specific lift avoids the worst of that by matching the router’s mount pattern and travel behavior.

If you try to force a plunge router into a motor-clamp lift, beginners often end up removing springs or disabling features. That can create a safety hazard if the router can free-fall in travel or if the plunge lock doesn’t hold under vibration.

Verify motor diameter

Measure your motor with calipers where the lift actually clamps, then compare against the model’s fit range. This one step prevents the most expensive mistake: buying a lift that “almost” fits, then chasing problems like binding travel or clamp marks on the motor can.

If you’re still sorting out your table setup, it helps to read a dedicated guide on router table basics so you don’t confuse table opening standards with router body dimensions.

Insert rings and accessories

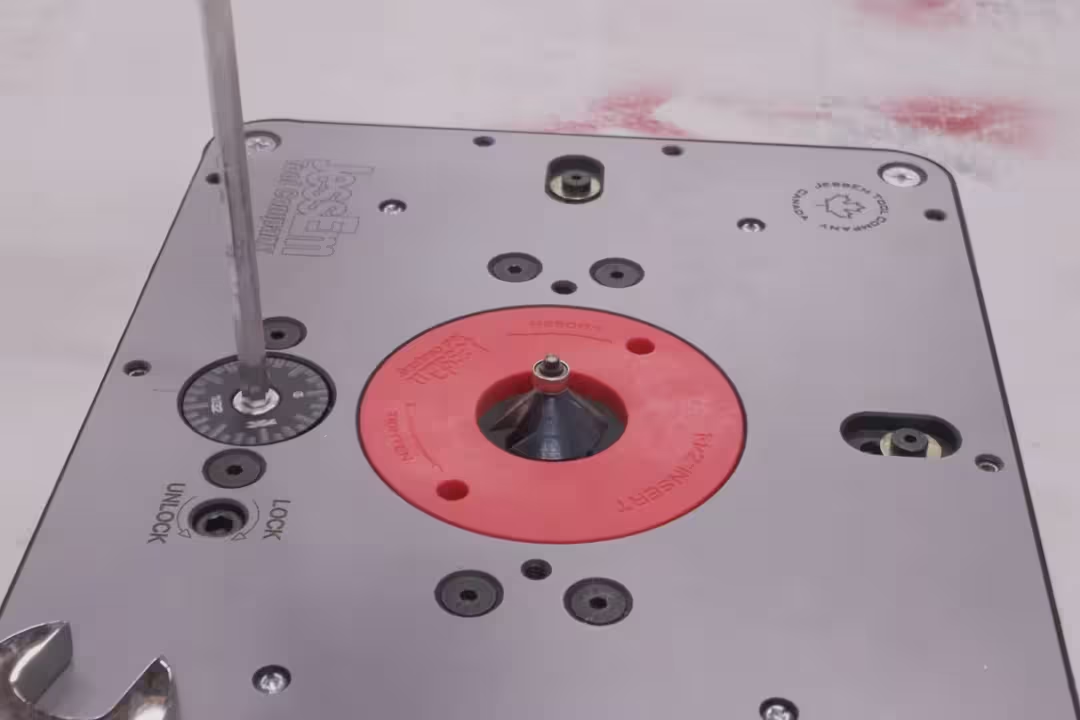

Tab-Loc insert rings

Tab-Loc rings matter more than people expect. A ring that sits flat and locks positively reduces the tiny lip that catches workpieces at the worst moment, when you’re feeding a narrow edge and your fingertips can feel every bump. The right ring also tightens chip control, so dust collection works more consistently.

Common mistake: running a small piece over a big opening. That’s when thin stock dips into the gap and you get a chatter mark or a sudden grab. Keep the ring opening as tight as practical for the bit diameter.

10-piece ring kit

A 10-piece kit earns its keep if you swap between pattern bits, straight bits, and larger profiles. In day-to-day routing, I reach for the smallest ring that clears the bit plus chips; that extra support reduces tearout at the trailing edge because the work stays flatter right at the cut.

Keep the rings clean. Resin and dust can make them feel “stuck,” and prying risks marring the plate. A soft brush and a quick wipe avoids that sticky, finger-squeak feel you get when pitch builds up on the ring edges.

Plate size options

Plate size is about more than drop-in fit; it affects stiffness and sag resistance. Bigger plates spread load across the table ledge, but only if the ledge is flat and supported. If the ledge is uneven, a larger plate can actually rock more until you level it with the set screws/snuggers.

Another easy-to-miss detail is corner radius. Some tabletops are cut for specific radii, so a plate that’s “the right size” still won’t seat without corner cleanup, which can void warranties or weaken the opening if you’re not careful.

Safety push blocks

Push blocks aren’t optional on a router table once you start doing small profiles. The cut can feel smooth for a second, then the bit grabs end grain and you feel that sharp tug through the stock. A good push block keeps your hands above the work and gives you downward pressure right over the ring opening.

Here are the common ring, plate, and safety add-ons people pair with JessEm lifts.

10 Piece Insert Ring Kit with Caddy

- Ten common insert sizes to match a range of bit diameters

- Handy caddy keeps rings organized and accessible

- Improves bit support for cleaner cuts

- Quick swap design speeds setup changes

- Compatible with Rout-R-Lift, Mast-R-Lift and Excell II systems

Mast-R-Lift II 8-1/4 inch by 11-3/4 inch Plate

- Generous 8-1/4 inch by 11-3/4 inch plate for stable mounting

- Precision lift mechanism for accurate height control

- Built in locking system holds settings securely

- Solid construction reduces vibration for cleaner cuts

- Easy to install and integrate with router tables

Mast-R-Lift Excel II Lift Only

- Precision lift mechanism sold as lift only for custom setups

- Built in locking system secures height during routing

- Fine adjustments for repeatable bit placement

- Solid construction for long term stability

- Compatible with many router plates and table systems

GrabberPRO Push Block

- Multi tool push block for table saws router tables band saws and jointers

- Non slip grip secures stock for safer cuts

- Low profile design improves visibility of the cut line

- Reduces kickback and increases control over workpieces

- Durable construction for frequent shop use

Installation and setup tips

Table opening fit

Start by confirming your tabletop opening matches the plate size and corner radius. If you have to force the plate into the opening, it will bind during seasonal movement and you’ll chase leveling issues forever. The plate should drop in with light hand pressure and sit down with a solid, dull thunk, not a springy bounce.

Don’t freehand enlarge an opening with a handheld router unless you have a proper template. The common beginner error is a wavy ledge that makes one corner low; that turns micro-adjustments into guesswork because the whole plate can shift under vibration.

Leveling and snuggers

Leveling is where most installs succeed or fail. Use the included snuggers (or your table’s leveling screws) to eliminate plate rattle, then confirm flatness with a straightedge across the seam. You’re listening and feeling for a click: run your fingernail across the joint; if it catches, the plate isn’t flush yet.

A pro workaround: set the plate a hair low, then bring it up to flush. If you start high and push down, the ledge can compress dust or chip debris and later settle, leaving the plate low mid-project.

Mounting the motor

Mount the motor with the power unplugged, then lightly snug the clamps before final tightening. Rotate the motor so the switch and cord route cleanly and won’t rub at full travel. You want a gentle strain relief loop, not a tight bend that stiffens in cold weather and tugs on the motor as it rises.

If your motor has a rubber overmold, don’t clamp on the soft section. Clamp on hard cylinder only; soft material creeps over time and can let the motor settle, which shows up as a changed bit height the next day.

Locking and adjustments

Make a habit: crank to height, lock, then do a short test cut. If you skip the lock on raised-panel or heavy round-over passes, the bit can climb slightly, leaving a profile mismatch you’ll feel when two parts meet. The lock should engage with a firm, positive stop.

If you’re trying to hit a precise height repeatedly, mark your crank position and count partial turns. That’s faster than chasing ruler marks, and it matches the way lifts are used in real joinery workflows.

Common fit problems

Most “bad lift” complaints come from three issues: the motor doesn’t match the clamp range, the plate isn’t level, or the table opening lacks support. Symptoms include binding travel, a ringing vibration sound, or an edge profile that changes width. Fix the mechanical stack—table flatness, plate seating, then motor clamp—before blaming the lift.

If you’re still deciding between lift styles, this internal guide on router lift selection helps you match features to table types without buying twice.

Price, value, and alternatives

Rout-R-Lift II value

Rout-R-Lift II tends to be the best value if you already own a compatible 3.5″ motor and want predictable results: clean height changes, reliable locking, and above-table bit work. It’s the option I recommend when the priority is repeatable joinery and you don’t need to swap router bodies.

The trade-off is future flexibility. If you later buy a different router with a slightly different motor body, you may have to replace the lift rather than adapt it.

Mast-R-Lift II value

Mast-R-Lift II costs more, yet it can pay off if you treat the lift as a long-term fixture and routers as consumables. Universal clamping reduces the odds you’ll get stuck when a favorite router model is discontinued or when you choose a different motor for noise, power, or speed control.

Expect a slightly longer setup phase. Once it’s dialed, it stays stable, but the initial clamp block positioning is where beginners can create problems that feel like “inconsistent machining.”

A good spec cross-check for the popular 8-1/4″ x 11-3/4″ plate variant is Infinity Tools Mast-R-Lift II 8-1/4″ x 11-3/4″, since plate size is a make-or-break detail for many tabletops.

Prestige value

The Prestige is valuable when your router choice forces it. If your workflow relies on a plunge router you don’t want to replace, then buying the lift that matches that platform can be cheaper than buying both a new router and a different lift. The real win is fewer compromises around bit changes and travel behavior.

Where people go wrong is assuming it’s an “upgrade” for any setup. If you’re using a standard 3.5″ motor router, a dedicated motor lift is often simpler and can feel more direct on small adjustments.

Budget alternatives

Budget lifts can work if your expectations match the reality: more variation in smoothness, more attention needed to keep fasteners tight, and sometimes less consistent ring fit. If you route occasionally and mainly want above-table access, a cheaper lift can be “good enough,” but for frequent joinery, the small annoyances add up fast.

Two common failure modes I see with budget options are backlash (you change direction and the bit doesn’t move right away) and height creep during heavy cuts. Workarounds include always approaching final height from the same direction and locking the carriage before every pass, even if it feels unnecessary.

Here are a couple of lower-cost alternatives people compare against JessEm models.

SpeTool Router Lift for 2.56 to 4.21 inch Routers

- All aluminum construction for light weight and rigidity

- Fits routers from 2.56 inch to 4.21 inch diameter

- Includes three magnetic insert rings for secure seating

- Large 9-1/4 inch by 11-3/4 inch insert plate for stability

- Designed for easy installation and smooth height control

OSKOOL RTS05 Lift for 3-1/2 inch Motors

- Designed for 3-1/2 inch diameter router motors for broad compatibility

- 9-1/4 inch by 11-3/4 inch plate offers stable mounting

- Comes with 5 piece insert ring kit to match common bit sizes

- Smooth height adjustment for precise routing

- Sturdy build ensures consistent performance

Practical Notes From Real-World Use

The biggest surprise people hit is how much a lift exposes problems elsewhere. A precise lift will faithfully hold height, so if your cuts still vary, it’s often your fence face not being square, your tabletop not being flat, or your bit collet not fully seated. I’ve fixed “mystery” profile changes by cleaning the collet until it stopped feeling gritty and stopped leaving that faint burnt-dust smell on the shank.

Dust is the slow enemy. Fine MDF dust can pack into corners and make the crank feel heavier over time. If you notice a soft crunching feel at the same point in travel, stop and clean before forcing it; forcing can score parts and create persistent rough spots. Better dust collection at the fence, plus a quick blow-out after sessions, keeps the movement smooth.

Another real constraint is workflow around ring changes. If you leave one “middle” ring in all the time, you’ll eventually run a small part into a too-large opening and get a scare. I keep the ring wrench where my hand naturally goes, so swapping rings becomes automatic instead of a skipped step.

Last issue: motor clamps can loosen slightly after the first few heat cycles. The first time you run a long session, the motor warms, then cools and settles. Recheck clamp tightness after a few uses, then it typically stabilizes. This avoids the beginner panic of thinking the lift is failing when it’s just the system settling into place.

- Approach final bit height from one direction to reduce any perceived backlash.

- Lock the lift before heavy passes like panel raising or large round-overs.

- Use the smallest insert ring that clears the bit and chips to prevent workpiece dip.

- Recheck plate level after moving the table; a small shift can create a lip you’ll feel with a fingernail.

- Measure motor diameter at the clamp area, not at labels, grips, or vents.

FAQs

What Is The Difference Between JessEm Rout-R-Lift II And Mast-R-Lift II?

The Rout-R-Lift II Is A Compact, Precision-Focused Lift Best For Small To Medium Routers, While The Mast-R-Lift II Is A Heavier-Duty, Higher-Capacity Lift Built For Larger Motors And More Travel.

The Rout-R-Lift II Suits Hobbyists And Fine Routing; The Mast-R-Lift II Gives Extra Stability And Lift Range For Professional Or Heavy-Duty Setups.

Which Routers Fit A JessEm Rout-R-Lift II 3.5 Inch Lift?

A JessEm Rout-R-Lift II 3.5 Inch Lift Fits Most Router Motors Whose Base Footprint And Motor Diameter Match The Lift Opening, Typically many fixed-base and some plunge motors.

Common compatible brands include models from DeWalt, Bosch, Makita and Porter-Cable, but always verify the motor diameter and consult JessEm templates or the product fit guide before purchasing.

What Does JessEm Router Lift 2 Mean And Which Models Are II?

JessEm Router Lift 2 Indicates A Second-Generation Or ‘II’ Version Of A JessEm Lift, Signifying Design Updates Or Improvements Over The Original Model.

Models With The II Suffix Include Examples Like Rout-R-Lift II And Mast-R-Lift II; Check The Product Name To Confirm You Have The Updated Version.

Do I Need Insert Rings And What Sizes Come With JessEm Tab-Loc Rings?

Insert Rings Are Not Strictly Required But Are Highly Recommended To Support Small Router Bits, Reduce Vibration, And Improve Safety And Cut Quality.

JessEm Tab-Loc Rings Are Sold As Optional Sets In Common Opening Sizes; Available Diameters Vary By Kit, So Check The Specific Product Listing Or JessEm’s Sizing Chart To See Which Ring Sizes Are Included.

How Do You Install And Level A JessEm Router Lift In A Router Table?

Install And Level A JessEm Router Lift By Mounting The Lift Plate To Your Table, Securing It Firmly, Then Adjusting The Lift Top So It Sits Flush With The Table Surface.

Use A Straightedge Or Dial Indicator To Check For High Or Low Spots, Adjust The Leveling Screws Or Shims Until Flush, Tighten The Mounting Bolts, And Test With A Bit To Confirm Accurate Height And Runout.