Jointer Planer Combo: 5 Picks to Choose with Confidence

Want to save shop space and handle both edge jointing and thickness planing with one machine? A jointer planer combo does both and frees up floor room. This short guide covers the basics, benefits, and five top models — including Grizzly options — so you can pick the right tool for your shop. Expect clear specs and simple buying tips to help you decide.

Table of Contents

A jointer planer combo gives you two core milling steps—flattening and thicknessing—in one machine, using one cutterhead. This guide explains how combos work, why they fit small and pro shops, and which models offer the best value for common woodworking projects.

Jointer planer combo basics

What it is

A planer jointer combo is one machine that works as a jointer (to create one flat face and a square edge) and as a thickness planer (to make the opposite face parallel and bring boards to final thickness). Most combination jointer planer units use a single cutterhead and switch modes by lifting or flipping tables, so you don’t buy, wire, and place two separate machines.

That one-cutterhead layout matters because it cuts setup time in small shops: you reference the same cutterhead height and cutter geometry for both operations, then switch the tables and dust hookup. If you’re still weighing separate machines, this overview of jointer types and setups can help you map combo features to real jointing tasks.

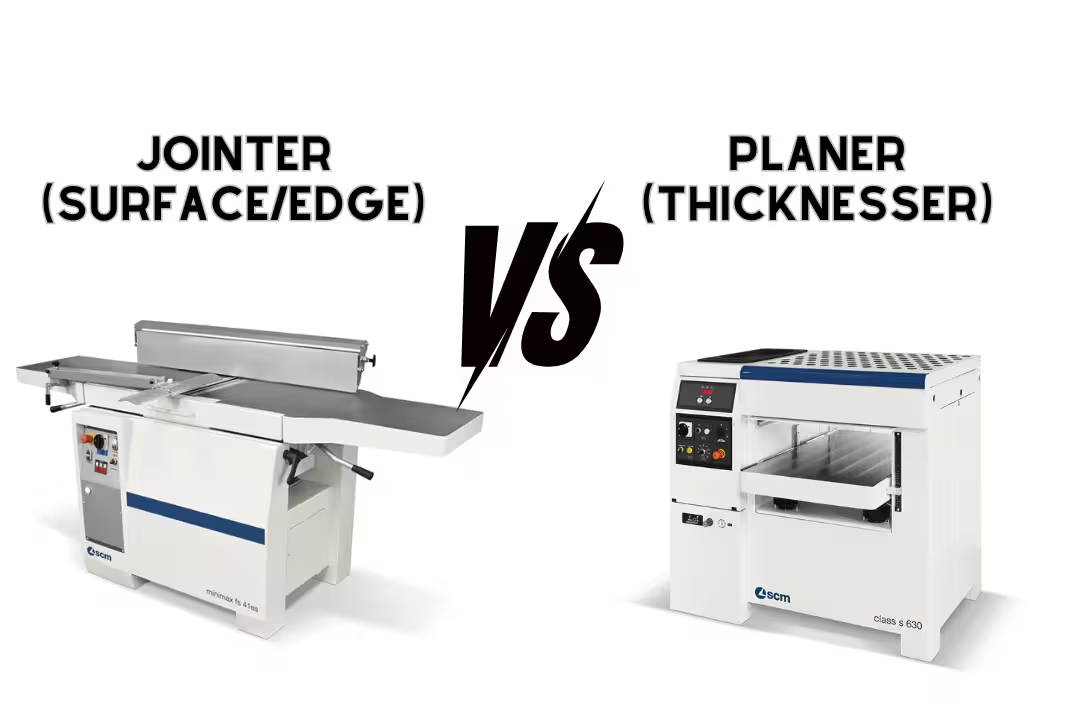

Jointer vs planer

A jointer makes one face flat and one edge square to that face, so boards stop rocking and edges glue up clean. You use it before the planer because a planer follows the shape of the board’s first face; if that face is twisted, the planer can “copy” the twist into a thinner board.

A thickness planer makes two faces parallel and brings stock to a consistent thickness. A common beginner workflow is: joint one face, joint one edge, plane the opposite face to thickness, then rip to width and lightly clean up the saw marks if needed.

Capacities, width

Most combo shoppers start by matching cutting width to their typical lumber. An 8-inch combo fits many hobby projects and smaller furniture parts; 10–12 inches opens the door to wider panels, table tops, and fewer glue-ups when working with rough hardwood.

Depth of cut is also a practical limiter: many combos are happiest taking lighter passes for better finish and fewer stalls. Typical maximums run around 1/8 inch on the jointer side, while planer passes often land in the 3/64–1/16 inch range for steady feeding and cleaner results.

Conversion time

Conversion is the tradeoff for space savings. Many benchtop-style combos switch in well under a minute: lift the jointer tables out of the way, move or lock the fence, and connect dust collection to the active port.

To keep changeovers smooth, batch your work: joint all boards first, then plane them all to thickness. That simple habit reduces mode switching, keeps your reference settings consistent, and helps you spot grain direction issues before you remove too much material.

Why choose a planer jointer combo

Space savings

A combo can free up floor space for the tools that actually need infeed/outfeed room, like your table saw and workbench. This is a big deal in one-car garages where the “real size” of a machine includes the clear runway for long boards.

If you’re planning your layout, place the combo so long stock can pass without hitting a bench, wall, or door track. Keeping the dust hose and power cord routed along a wall also cuts trip hazards and makes it easier to switch modes without dragging hoses across the floor.

Cost advantages

Combos can lower total cost because you’re paying for one base, one motor system, and one cutterhead instead of two complete machines. Research summaries often cite meaningful savings compared with buying separate machines, especially when you factor in stands, mobile bases, and dust fittings.

For a quick reality check, compare prices and footprints for an 8-inch jointer plus a 12–13 inch portable planer versus a single 8–10 inch combo. The combo may cost less upfront, but the bigger win is often avoiding a cramped shop where boards become hard to control.

Workflow, feed rates

A combo supports solo workflow because you can face-joint, edge-joint, then thickness boards without moving material across the shop. Many units run planer feed speeds around 19–22 feet per minute, which is fast enough for batching parts without feeling rushed.

Good workflow comes from predictable passes: take heavier cuts only when the board is short, straight-grained, and well supported. On long boards, lighter passes reduce chatter, reduce snipe risk, and keep the motor from bogging down mid-feed.

Helical cutterhead perks

A helical or spiral head uses carbide inserts that can be rotated to a fresh edge when you hit a knot or dull the cutter. Many heads let you rotate each insert up to three times before replacement, which can cut both downtime and long-term blade costs.

Helical heads also help with tearout on tricky grain because the cutters meet the wood at a shearing angle. If you build with figured maple, oak with reversing grain, or reclaimed lumber, that smoother cut can save you sanding time later.

Top 5 jointer planer combo picks

Grizzly G0958 8-inch combo

The Grizzly G0958 is a strong “best overall” pick if you want an 8-inch combination jointer planer with a helical cutterhead. Commonly cited specs include a 1.5 HP 120V motor and an 18-insert carbide head around 8,500 RPM, which aims for clean results on softwoods and many hardwoods with light passes.

It’s also popular for quick changeovers and manageable weight for a benchtop class machine. If you’re comparing a grizzly jointer planer combo against other 8-inch units, focus on table rigidity, fence stiffness, and how easy it is to connect dust collection in both modes.

Grizzly G0958 8 Inch Jointer with Helical Cutterhead

- Eight inch woodworking jointer for flattening and squaring boards

- helical cutterhead with carbide inserts for smoother cuts and less tearout

- powerful motor handles hardwoods with ease

- cast iron tables provide stability and accuracy

- ideal for serious hobbyists and professional shops

JET JPJ-12BHH 12-Inch Jointer with Helical Cutterhead

The JET JPJ-12BHH is a heavy-duty 12-inch jointer built for professional and high-demand woodworking shops. It has a strong industrial motor and a helical cutterhead with carbide inserts. This setup provides very smooth cuts and reduces tearout, even on tough hardwoods or detailed wood grain.

Users like the large 12-inch capacity and the long, smooth cast-iron tables. These features give great board support and steady accuracy. The helical cutterhead is quieter than straight-knife jointers. It needs less maintenance and allows for individual insert rotation. This means you don’t have to change the whole blade. It is a great upgrade for serious woodworkers who want to boost productivity.

JET JPJ 12BHH 12 Inch Jointer with Helical Cutterhead

- Twelve inch heavy duty woodworking jointer for wide boards

- helical cutterhead with carbide inserts delivers smooth finishes and reduced tearout

- powerful industrial motor handles hardwoods with ease

- long precision ground cast iron tables ensure accuracy

- ideal for professional shops and serious woodworkers

JET JJP-12HH Jointer Planer Combo with Helical Cutterhead

The JET JJP-12HH is a space-saving 12-inch jointer-planer combo designed for serious woodworking shops. Its helical cutterhead with carbide inserts produces smooth, low-tearout cuts and runs quieter than straight-knife machines, even on hardwoods and figured grain.

This machine offers quick changeover between jointing and planing. It has a powerful motor and heavy cast-iron tables for stability. This design provides professional results without needing two separate tools. It is a smart long-term investment for high-accuracy milling.

JET JJP 12HH Jointer Planer Combo with Helical Cutterhead

- Twelve inch jointer planer combination machine saves shop space

- helical cutterhead with carbide inserts delivers smooth cuts and low tearout

- quick changeover between jointing and planing modes

- powerful motor handles hardwoods with ease

- heavy cast iron tables ensure stability and accuracy

Grizzly G0959 12-inch combo

The Grizzly G0959 targets woodworkers who want 12-inch capacity without moving to a full industrial-format machine. A 12-inch planer jointer combo is a practical step up for furniture makers because it reduces the need to rip wide boards before flattening.

If you do lots of panel work, wider jointing capacity can mean tighter glue-ups and less time fighting spring joints. Pair the machine with strong dust collection and sharp inserts, and you’ll spend less time sanding out torn grain.

Grizzly G0959 12 Inch Jointer with Helical Cutterhead

- Twelve inch heavy duty woodworking jointer for wide boards

- helical cutterhead with carbide inserts delivers smooth cuts and reduced tearout

- powerful motor handles dense hardwoods with ease

- long cast iron tables ensure accuracy and stability

- ideal for professional shops and serious woodworkers

Grizzly G0634X 12-inch 5 HP combo

The Grizzly G0634X is a heavy-duty 12-inch combination jointer planer aimed at serious production and demanding hardwood milling. It’s commonly cited as a 5 HP 220V machine with cast-iron tables around 59.5 inches long and a 48-insert V-helical head, which supports steady feeding and cleaner cuts when you’re processing a lot of stock.

Weight is part of the value here: a heavy machine tends to vibrate less and hold settings better. Plan for proper electrical supply, a mobile base rated for the load if you must move it, and dust collection sized for dual 4-inch ports.

Grizzly G0634X 12 Inch Jointer with V Helical Cutterhead

- Twelve inch professional woodworking jointer for wide stock

- V helical cutterhead with carbide inserts for ultra smooth cuts and low noise

- powerful motor handles hardwoods with ease

- long precision ground cast iron tables ensure accuracy

- built for serious shops and production work

| Model | Best fit | Why it stands out |

|---|---|---|

| Grizzly G0958 (8″) | Small shop, smoother finish | Helical inserts; compact benchtop format |

| Jet JJP-8BT (8″) | Budget-minded milling | Simple straight-knife head; approachable controls |

| Jet JJP-10BTOS (10″) | Wider boards on 120V | 10″ capacity; stand option for better ergonomics |

| Grizzly G0959 (12″) | Furniture parts, wide stock | 12″ capacity; insert-style head on many configs |

| Grizzly G0634X (12″, 5 HP) | High volume, heavy hardwood | Cast iron mass; 220V power; V-helical head |

Choosing with confidence: specs that matter

Cutterhead type

Your cutterhead drives surface quality, noise, and maintenance, so start here for a smart comparison. Straight knives cost less up front and can cut cleanly, but they demand careful setting and full-knife changes when one edge chips.

Helical or spiral insert heads cost more, yet they’re easier to live with: rotate a single insert after damage, keep cutting, then rotate the rest later on your schedule. If you want a deeper technical explanation of milling steps and where each tool fits, bookmark woodworking tips and guides for in-shop reference.

Power, voltage

Match the machine to your shop’s available power. Many benchtop combos run on 120V circuits, which is convenient, but heavier 12-inch combos often want 220V for higher horsepower and better performance when taking wider passes in hardwood.

If you’re frequently flattening rough lumber, more power means fewer stalls and less temptation to take too-heavy cuts. Think in habits: a lighter pass with steady feed usually beats pushing any machine to its limit.

Width and depth

Width determines what you can flatten in one go, but depth control determines how smoothly you get there. A combo that reliably takes consistent 1/32-inch passes will often beat a machine that claims deeper cuts but struggles to feed without chatter.

A practical shopping rule: buy the widest machine you can support with space, power, and dust collection, then plan to take lighter passes on difficult grain. That approach yields flatter parts and reduces the risk of tearout that forces you into heavy sanding.

Table length, fence

Longer jointer tables support straighter results because the board stays registered across more surface area, which improves jointing accuracy. Short tables can still work, but you’ll want infeed/outfeed stands for longer stock to prevent the board from tipping and creating a bow.

Fence rigidity matters just as much: a fence that flexes can turn “square” into “close enough,” which shows up as gaps in panel glue-ups. Check that the fence locks firmly at 90° and holds common bevel angles if you build miters or beveled edge joints.

Dust collection ports

Plan for chips from day one because good collection improves cut quality and keeps inserts cooler, which helps edge life. Benchtop units often use 2.5-inch ports, while larger combos may use 4-inch ports (sometimes dual ports), so match your hose and collector capacity before you buy.

If you’re building out a compact shop system, a dedicated collector plus a good separator keeps airflow steadier than a shop vac alone. For small-shop layout ideas that pair well with combo machines, a workbench guide can help you balance milling space with assembly space.

If you only need 6 inches

Separate-tool alternative

If your projects stay under 6 inches wide, a small jointer plus a separate portable planer can be a better bargain than an 8-inch combo. This setup also lets one tool run while the other stays dialed in, which reduces mode switching during busy build days.

Here are beginner-friendly 6-inch jointer and planer options to compare side-by-side.

WEN JT630H Compact 6 inch Jointer

- Powerful 10 amp motor delivers smooth, consistent cutting

- 6 inch spiral cutterhead for clean, tearout-free surfaces

- Adjustable fence and depth controls for precise edge work

- Stable benchtop design fits small shops and workbenches

- Easy maintenance and quick cutterhead access for fast blade changes

CRAFTSMAN High-Speed Benchtop Jointer

- Up to 22,000 cuts per minute for fast, smooth stock removal

- 10 amp motor balances power and control for everyday joinery

- Compact footprint saves shop space while handling common boards

- Precise fence adjustment for accurate edge jointing

- Tool-free setup and simple adjustments speed workflow

DEWALT DW735X 13 inch Planer

- 13 inch cutting width handles wide boards and large panels

- Three-knife cutterhead produces smooth, flat surfaces

- Two-speed gearbox optimizes finish quality or rapid material removal

- 15 amp motor provides consistent power under heavy loads

- Rugged construction and cast components reduce vibration for accurate planing

WEN JT3062 Compact 6 inch Jointer

- 10 amp motor for reliable edge jointing and small stock removal

- 6 inch cutter width ideal for trim and small boards

- Two-blade cutter system balances performance and affordability

- Adjustable fence and cutter height for accurate setup

- Lightweight benchtop design for easy placement and storage

Cutech 40160HB 6 inch Spiral Jointer

- Spiral cutterhead with 12 TC inserts for quiet, chipper-resistant cutting

- Teflon coated aluminum tables for smooth stock feeding and corrosion resistance

- 10 amp motor delivers steady power for consistent passes

- Large 19 and 5/8 inch aluminum fence offers strong workpiece support

- Low maintenance design makes insert changes quick and user friendly

Pick this route if you often plane wide boards but only need light edge jointing on narrow parts, trim, and small panels. If you’re also setting up a router workflow for joinery after milling, a router table setup pairs well with a small-jointer-plus-planer kit.

Maintenance and safety for combination jointer planer

Insert rotation

With insert heads, build a simple habit around rotation intervals: mark each insert row after you rotate it so you don’t lose track. When you see fuzzy grain, burnishing, or new tearout on normal stock, rotate only the affected inserts first, then schedule a full set rotation when you have time.

Always clean the pocket before tightening: trapped dust can keep an insert from seating flat, which can create ridges across your work. A small nylon brush and a torque tool (if the maker specifies one) helps you get consistent seating and longer edge life.

Table cleaning, rust prevention

Clean tables often to keep feed smooth and reduce burn marks. Pitch buildup increases friction and forces you to push harder, which hurts accuracy and can pull your hands closer to the cutter area.

On cast iron, wipe down after use and apply a thin coat of a table protectant that won’t contaminate finishes. On aluminum tables, focus on removing resin and keeping the surface slick so boards don’t hesitate at the cutterhead.

Fence alignment checks

Check the fence at 90 degrees and at common bevel settings before a big batch of milling. A reliable machinist square beats eyeballing, and a fast check can save an entire glue-up from gaps and twist.

If your combo has an end-mounted fence or a sliding fence bracket, keep the locking surfaces clean and lightly lubricate adjustment points so settings don’t drift mid-job. Recheck after moving the machine or bumping it with long stock.

Dust collection, PPE

Use effective dust collection because fine wood dust is a health risk and chips in the cutter area can mar the surface. For safety, wear eye protection, use hearing protection, and add a respirator when milling resinous woods or sanding your freshly planed parts.

Use push blocks on the jointer every time, keep guards in place, and don’t joint stock that’s too short for your machine’s rules. For broader shop safety and cleanup routines that support milling work, a guide to sanding machines can help you plan dust control from milling through final finish prep.

FAQs

What Is The Difference Between A Jointer-Planer Combo And Separate Jointer And Planer Machines?

A Jointer-Planer combo combines both functions in one machine but usually sacrifices some performance, capacity, and setup flexibility compared with separate jointer and planer machines.

Separate machines typically offer longer beds, heavier-duty cutterheads, independent adjustments, and better stability for repeated production work; combos save space and cost for hobbyists or small shops that accept trade-offs.

Are Jointer-Planer Combos Accurate And Stable Enough For Professional Woodworking?

Some high-quality jointer-planer combos can achieve professional-level accuracy for light to moderate shop work, but many lack the mass and rigidity of dedicated machines.

Build quality, cast-iron tables, cutterhead construction, and careful setup determine results; for heavy production, separate machines usually provide greater stability and repeatability, though a well-tuned combo can serve small pros.

How Do I Set Up, Align, And Calibrate A Jointer-Planer Combo For Flat And Square Boards?

Set up a jointer-planer combo by truing the tables, aligning the fence, and calibrating the cutterhead and bed height to produce flat, square boards.

Use a long straightedge or precision level and a dial indicator to check table and bed flatness, shim or adjust surfaces until consistent, then make incremental test passes on scrap and recheck angles as you fine-tune.

Which Jointer-Planer Combo Offers The Best Value And Reliability Under $1000?

Under $1000, the best-value jointer-planer combos prioritize solid construction, reliable motors, and precise fences over extra features rather than one specific model.

Look for cast-iron or heavy-gauge tables, a robust cutterhead, clear adjustment mechanisms, a good warranty and positive user reviews; if you need higher capacity or accuracy, consider used separate machines for better long-term value.