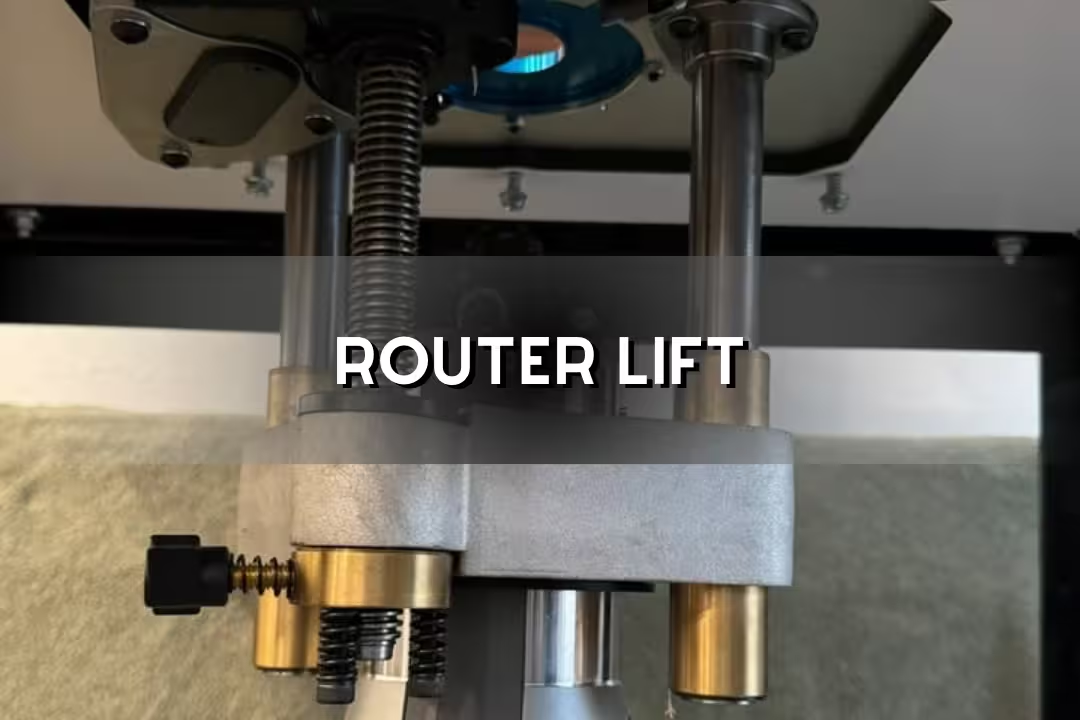

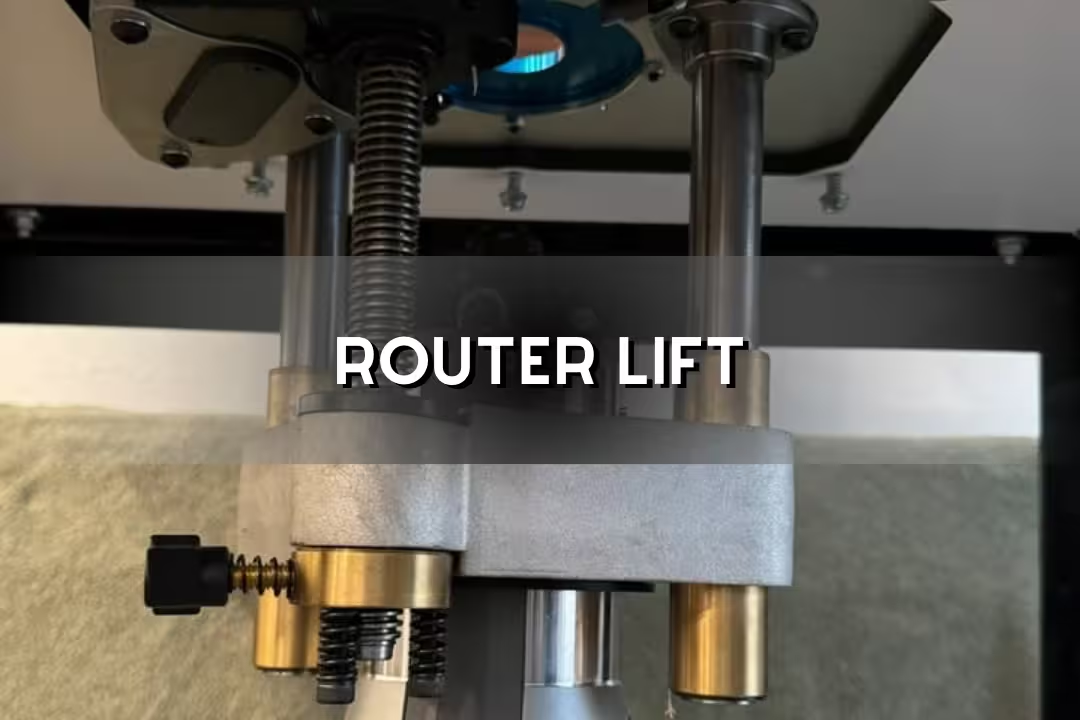

Router Lift: 5 Ways to Buy with Confidence

Worried your new router lift won’t fit or feel solid? A good lift makes bit height changes fast and accurate. This guide gives five clear ways to buy with confidence. You will learn simple compatibility checks, which precision features matter, how to judge build quality, what to expect for above-table bit changes, and where to read helpful reviews. Read on and pick a lift that fits your tools and table.

Table of Contents

A router lift turns bit height changes into fast, repeatable adjustments from above the table. This guide shows how to check fit, pick precision features, and compare popular lifts like the Jessem router lift and Kreg router lift.

Router Lift Compatibility Checks

Most problems with router lifts come from mismatch: the motor doesn’t clamp, the plate doesn’t fit the opening, or the router can’t reach a bit-change position. Start with measurements and model lists before you buy, especially if you’re upgrading an existing router table setup.

Motor diameter

Measure your router’s motor can with calipers (or a good tape) and match it to the lift’s clamp range; 3.5-inch motors are common for routers like the DeWalt 618, Bosch 1617/1618, and others. If you’re close to the limit, don’t “force-fit” it—choose a lift that matches the motor size so it clamps evenly and won’t slip during heavy cuts.

Many plates use the “standard” opening size but still clamp different motor diameters, so treat diameter as a separate pass/fail check. For a quick reference on common sizes and router families, cross-check specs on a trusted reference like WOOD Magazine router lift guidance before ordering.

Router model fit

Look for a published router list for the lift (not “universal” wording) and confirm your exact model, especially with older motors or oddball housings. Jessem’s Rout-R-Lift II uses clamping blocks sized for common motors, while the Kreg PRS5000 is known for wide compatibility without extra adapters—either way, verify your router name and motor style (fixed base motor vs dedicated table motor).

If you run a big 3+ HP motor, check for any notes about removing handles, switch clearance, or depth stop interference. A lift can be “compatible” but still annoying if the switch ends up blocked under the table, so plan your on/off control and dust routing from the start.

Plate size standard

Most premium router table lift plates follow the common 9-1/4 x 11-3/4 format, often around 3/8-inch thick, which fits many tables and top systems. Still, don’t guess—check both the plate’s outer dimensions and the corner radius, since some openings need corner relief to drop in flat.

| Check | What to measure | What “good” looks like |

|---|---|---|

| Motor diameter | Outside diameter of motor can | Matches lift clamp spec (ex: 3.50″) |

| Plate size | Plate outer length/width/thickness | Matches your table opening spec |

| Corner radius | Plate corners vs table corners | Plate sits flat with no rocking |

| Bit clearance | Insert ring opening and plate hole | Fits largest bit you plan to use |

Measure table opening

Pull your current insert plate and measure the opening length, width, and depth of the rabbet/ledge that supports the plate. If the opening isn’t standard, you can still use many lifts, but you may need a new top, an adapter ring, or careful routing with a template to avoid gaps that catch workpieces.

Check leveling screws and any corner set screws that keep plates from shifting during vibration. If your table top is worn or sagging, fix that first—no lift can stay accurate if the plate isn’t supported evenly on all sides.

JessEm Rout-R-Lift II Precision Lift

- Micro-adjust knob for fine tuning router height

- Designed for 3.5 inch diameter motors and common router models

- Robust construction reduces wobble and improves accuracy

- Clear scale and easy adjustments speed setup time

- Durable mechanism for long workshop use

Kreg PRS5000 Professional Router Lift

- Micro-adjustment for accurate, repeatable bit height settings

- Heavy-duty plate and mechanism for professional use

- Fast, consistent setups that save time on repeated cuts

- Compatibility with common router table inserts and accessories

- Built for durability and longterm reliable performance

Precision Features to Prioritize in Router Lifts

Precision is where a router table lift earns its cost: you can return to a previous setting, sneak up on a fit, and run repeated parts without chasing height. Focus on adjustment feel, repeatability, and how well the lift holds position under vibration.

Micro-adjust scale

A good micro-adjust system gives predictable increments you can repeat across sessions. Look for a scale that’s easy to read and a crank that doesn’t bind; if one full turn equals a known change (like 1/16-inch), you can track adjustments quickly during joinery and profiling.

Backlash-free bearings

Backlash shows up as “dead travel” when you reverse direction, which ruins repeatability for dados and edge profiles. Lifts with ball-bearing support and tight lead-screw fit tend to move smoothly with less slop, so you can raise or lower a few thousandths without overshooting.

Above-table crank

Above-table cranks save time because you can adjust height without reaching under the top, where dust collection hoses and cabinet walls get in the way. This matters a lot if your table is enclosed or if you run a dedicated station like a Kreg router table with storage and dust ports.

Locking mechanism

A positive lock keeps the setting from creeping during long runs, heavy panel-raising, or vibration from large bits. Look for a simple lock you’ll actually use every time; if it’s awkward, you’ll skip it and blame the lift for drift.

Digital readout option

A digital readout can speed setups when you swap bits often or need exact offsets between passes. Treat it as a convenience add-on rather than a fix for poor mechanics—smooth travel and low backlash still matter more than the number on the screen.

- Match your measuring habit: if you set height with test cuts, prioritize smooth feel and lock strength.

- If you build batches, prioritize repeatability: clear scale markings and low backlash.

- If multiple people use the table, prioritize fast setup: above-table crank access and easy locks.

Build Quality and Durability for Router Table Lifts

Build quality decides whether your lift stays flat, holds alignment, and keeps working after years of dust and use. Pay attention to the plate, the guide system, and the parts that take load every time you change height.

Plate materials

Plates made from hard-anodized aluminum resist scratches and stay flatter than thin cast plates. A flat plate surface matters because even a small dip changes depth of cut and can cause burn marks on edge profiles.

Load capacity

Check the lift’s stated support for heavier 3+ HP motors if you run big diameter bits or long sessions. A lift that handles real router weight won’t sag over time, which helps keep joinery consistent across months of use.

Wobble control

Wobble usually comes from play in posts, carriage fit, or the lead screw system. Look for tight machining, solid guide posts, and anti-play design so the bit doesn’t shift sideways when you feed stock firmly against the fence.

Corrosion resistance

Humidity and MDF dust can corrode unprotected steel parts and lock up fine adjustments. Anodized aluminum, stainless hardware, and sealed bearings improve long-term smoothness, especially in garages and sheds.

These product options are often compared for fit range and plate size in common tables.

O'SKOOL Router Lift Kit for 3-1/2 inch Motors

- Precision height adjustment for accurate cuts

- Fits 3-1/2 inch diameter motors for wide compatibility

- Durable 9-1/4 inch x 11-3/4 inch plate for stable mounting

- Five-piece insert ring kit allows quick bit changes and snug fits

- Simple install and smooth lift action for repeatable setups

SpeTool Adjustable Router Lift 2.56 to 4.21 inch

- Wide compatibility covering 2.56 inch to 4.21 inch router diameters

- All-aluminum construction for rigidity and corrosion resistance

- Includes three magnetic insert rings for secure bit centering

- Standard 9-1/4 inch x 11-3/4 inch plate fits common tables

- Comes with DIY template for straightforward installation

Above-Table Bit Changes and Insert Rings

Bit changes are where a lift adds daily value: you spend less time pulling motors out and more time cutting. Plan for collet access, wrench clearance, and ring sizes before you commit to a plate system.

Collet access

Some lifts raise the router high enough that the collet clears the plate for above-table changes. Confirm that your router’s spindle height and the lift’s maximum travel let the collet sit above the insert ring so you can swap bits without removing the motor.

Offset wrenches

Offset wrenches help when the collet is close to the plate opening or when your cabinet limits hand room. If your router needs two wrenches, confirm you can hold the shaft and turn the collet nut with safe knuckle clearance.

Insert ring kits

Insert rings reduce the gap around the bit, which supports workpieces and improves dust control. Aim for a kit with multiple sizes, a ring style you can remove fast, and a snug ring fit that won’t spin loose during a cut.

Large bit clearance

If you run raised-panel bits, large round-overs, or profile bits with big bearings, check the maximum opening size. Confirm the plate and ring system provide large-bit clearance so the cutter doesn’t contact the ring at startup.

For practical safety limits and cutter guidance, use a trusted reference like CPSC Recalls to check for any router or accessory recalls before heavy use, especially when buying older tools secondhand.

Reviews, Warranties, and Value Comparison

Specs tell you what the lift should do; reviews tell you what it does after months of dust, vibration, and real shop schedules. Combine user feedback with warranty terms so you pay for usable accuracy, not marketing claims.

Where to check reviews

Check a mix of Amazon reviews, woodworking forums, and YouTube setup videos so you see both install pain points and long-run reliability. Give extra weight to reviews that mention router model, table top type, and whether the user runs large bits or heavy motors.

Jessem vs Kreg feedback

Feedback on a Jessem router lift often highlights smooth travel and solid value for common 3.5-inch motors, while the Kreg router lift is often chosen for professional-feel adjustments and repeatability. Before you pick, confirm which one better matches your day-to-day workflow: frequent bit swaps, batch runs, or occasional weekend projects on a Bosch router table.

Warranty terms

Read warranty coverage for wear items (lead screws, bearings, inserts) and what counts as normal shop use. A strong warranty with clear support channels adds real value if you depend on the lift for paid work.

Price ranges

Entry lifts often start around the low-to-mid $200 range, while premium options can approach $400 once you add extra rings or accessories. Instead of chasing the cheapest price, match spend to what you cut most: cabinet doors, dado work, pattern routing, or fine joinery.

Return policies

Confirm the return window and whether you can return an opened lift if the plate doesn’t fit your opening. Keep packaging until you verify three things on day one: plate sits flat, motor clamps securely, and your above-table access works with your fence and dust setup.

FAQs

What Is A Router Lift?

A router lift is a device that mounts under your router and lets you raise or lower the bit from above the table.

It replaces manual access to the router’s adjustment, giving precise, repeatable height control and safer bit changes. Router lifts fit many table-mounted routers and come in DIY and commercial models.

Do I Need A Router Lift?

You don’t strictly need a router lift, but it improves accuracy and convenience when working at a router table.

If you do frequent, precise edge work, profiling, or production runs, a lift saves time and reduces setup errors. Hobbyists who only rout occasionally can manage without one, but many find the convenience worth the cost.

How Does A Router Lift Work?

A router lift raises and lowers the router bit using a mechanical crank or gear mechanism mounted beneath the table.

The router is attached to a carriage or platform that moves vertically, and a graduated adjustment lets you make fine, repeatable changes. Some lifts include micro-adjusters and locking rings for exact depth control during production work.

How To Build A Router Lift?

You can build a simple router lift by making a rigid carriage, a threaded lift screw, and a top plate to secure the router under the table.

Start with accurate measuring of your router’s base, choose a sturdy screw and bearings for smooth travel, and add a crank for adjustments. Always test for stability, add a reliable locking method, and follow safety guidelines.