Mini lathes: 7 top models to buy

Mini lathes fit on a small bench and still make clean parts. They handle wood and metal with good precision. This guide reviews seven top models, from compact mini wood lathes to more powerful benchtop options. Read on for clear picks, key specs, and simple safety tips for any mini lathe machine.

Table of Contents

Mini lathes make it possible to turn accurate parts in a small shop without buying a full-size machine. This guide explains types, sizes, buying specs, and the best mini lathe picks for 2026.

Mini lathes overview

A mini lathe is a compact machine for shaping spinning stock with a cutting tool, and many models fit a benchtop setup. You’ll see versions built for wood, metal, or mixed light-duty work, so your first step is matching the machine to what you’ll actually cut.

Mini lathe types

The big split is between a mini wood lathe (optimized for higher spindle speed and lighter cutting loads) and a metal-focused mini lathe machine (built for torque, rigid slides, and controlled feeds). Combo “mini lathe” kits also exist, but they usually trade rigidity and accuracy for convenience, so treat them as light-duty tools for plastics, wood, aluminum, and very mild steel work.

If you want to compare metal mini lathe specs across common sizes (swing, bore, threading ranges), lathe comparison is a helpful reference list for feature-by-feature checks.

Typical sizes

Most mini metal lathes land in the 7–9 inch swing range with 12–20 inches between centers, often described as 7×14 or 7×16. These machines can weigh roughly 90–264 lbs, so they’re small enough for a bench but heavy enough to demand a stable stand and good mounting.

Common features

Look for variable speed, a 3-jaw chuck (common for round stock), and a tailstock with a standard Morse taper so tooling is easy to source. For metalwork, smooth cross-slide travel, a usable threading/feed setup, and low backlash in the handwheels matter more than fancy add-ons.

Why mini lathes are worth it

A smaller machine can still produce clean work if you match the tool to the job and keep setups rigid. Mini lathes shine for repeatable parts, quick prototypes, pen turning, bushings, spacers, knobs, and small fittings where control matters more than raw size.

Precision control

Mini lathes often feel “precise” because you can take light passes and react quickly using fine handwheel inputs and steady speed control. Digital readouts and tachometers help you hold consistent diameters and surface finish, especially when you’re learning how tool geometry and feed rate affect chip load.

Space-saving benchtop setup

A benchtop lathe can live in a garage corner and still stay ready to use if you build a solid workstation. A stiff bench, good lighting, and a dedicated tool rack reduce setup time, and a purpose-built surface like a woodworking bench makes it easier to bolt down the machine without racking; see woodworking workbenches for ideas.

Versatile materials

With the right cutters and speeds, mini lathes can handle wood, plastics, brass, aluminum, and light steel work. The key is matching torque and rigidity to the material: wood favors higher RPM, while steel needs lower RPM and firm workholding to stop chatter.

Mini lathes buying factors

Mini lathe shopping goes faster if you treat it like a spec checklist: capacity, motor, spindle tooling, stability, and ergonomics. Missing one spec can limit projects more than you’d expect, so decide what parts you want to make, then buy around constraints.

Swing and centers

Swing over bed sets maximum diameter, and distance between centers sets maximum length between headstock and tailstock. If you plan to turn pen blanks, small bowls, bushings, or short shafts, a 7×14 class machine often works; for longer spindles, step up in centers length, not just swing.

Motor and RPM

Power ratings vary widely, from tiny 36W hobby machines to 650W+ benchtop metal lathes, and that affects how easily you can cut steel without stalling. A wide RPM range is useful, but steady low-speed torque and smooth control matter most for metal and for safe roughing cuts.

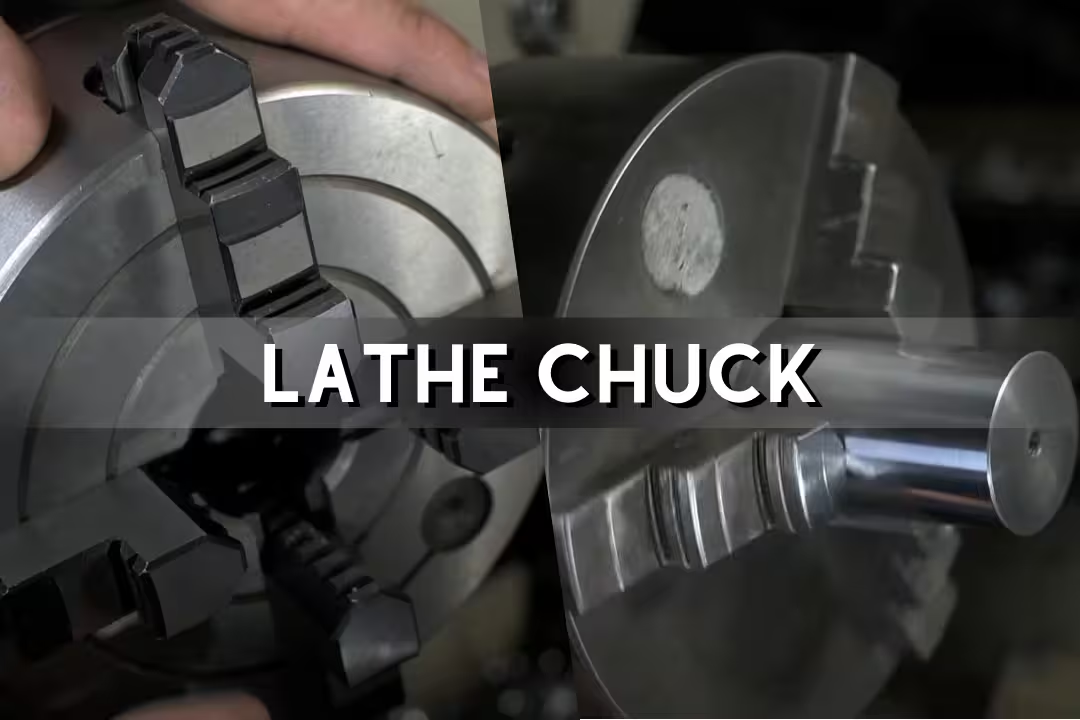

Chucks and tapers

Most buyers start with a 3-jaw chuck, then add a 4-jaw independent chuck when they need accurate centering on non-round stock. Check the spindle nose and tailstock Morse taper because common tapers make it easier to add live centers, drill chucks, and specialty arbors later.

Power and weight

Mini lathes often run on 120V household power, but amps can rise as motor size increases, so confirm your outlet and breaker capacity. More weight usually means more stable cuts, yet it also means you need a bench that won’t flex, a plan for moving the machine, and solid mounting hardware.

Vibration and ergonomics

Chatter comes from flex in the workpiece, tool, or machine, so look for rigid ways, tight gibs, and a stable base before you pay for extra accessories. Good ergonomics also matter: clear speed controls, reachable emergency stop, and handwheels that turn smoothly help you make cleaner parts and fewer mistakes.

- Pick the largest swing you’ll truly use, then prioritize centers length for your common projects.

- Choose torque and low-speed control for metal; choose higher top speed for wood and small diameters.

- Budget for workholding upgrades (4-jaw chuck, better jaws, live center) early.

- Plan the bench and mounting before the machine arrives so vibration stays low.

Mini lathes: top 7 models to buy in 2026

Here are seven popular mini lathes worth comparing side-by-side based on capacity, features, and use case.

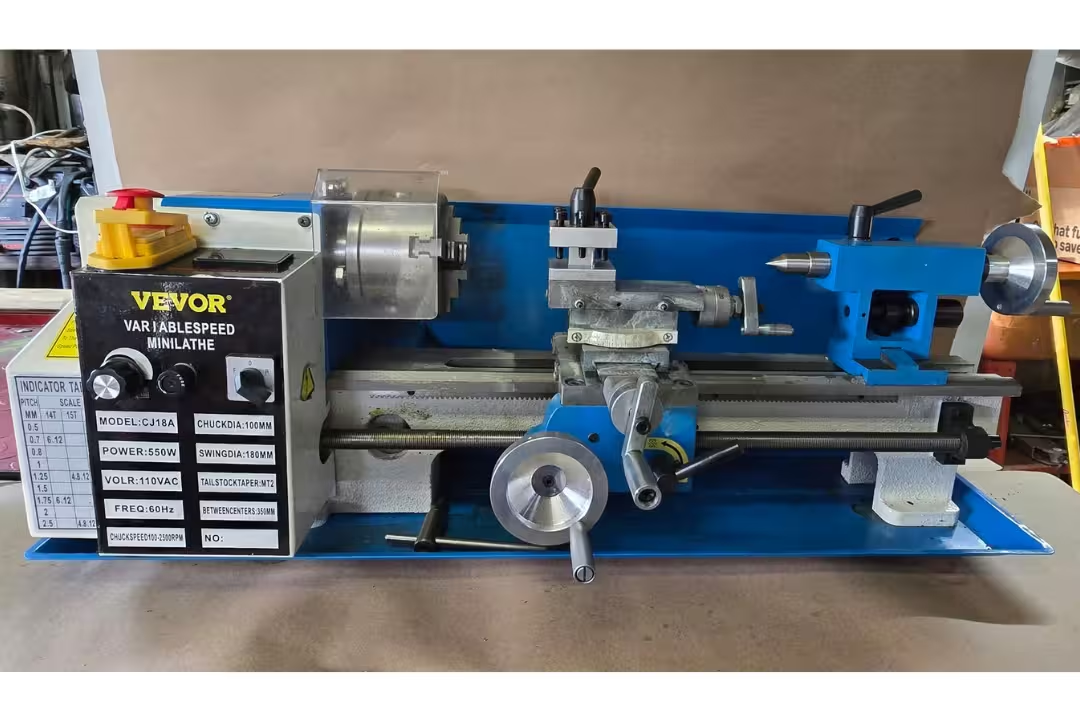

Editor’s choice: VEVOR 7×14 Precision

If you want a do-it-most option, this 7×14 class unit hits the sweet spot of capacity and control with a 550W-class motor and variable speed up to about 2250 RPM. Use it for bushings, spacers, small shafts, and light facing jobs, then upgrade tooling as your projects get more demanding.

VEVOR 7 inch x 14 inch Precision Lathe

- Upgraded digital readout for clear speed and position monitoring

- 550W motor with variable speed up to 2250 RPM for smooth metal cutting

- 3 jaw chuck simplifies secure workholding for round parts

- Sturdy benchtop construction reduces vibration for accurate finishes

- Compatible with common tooling and hobby CNC attachments

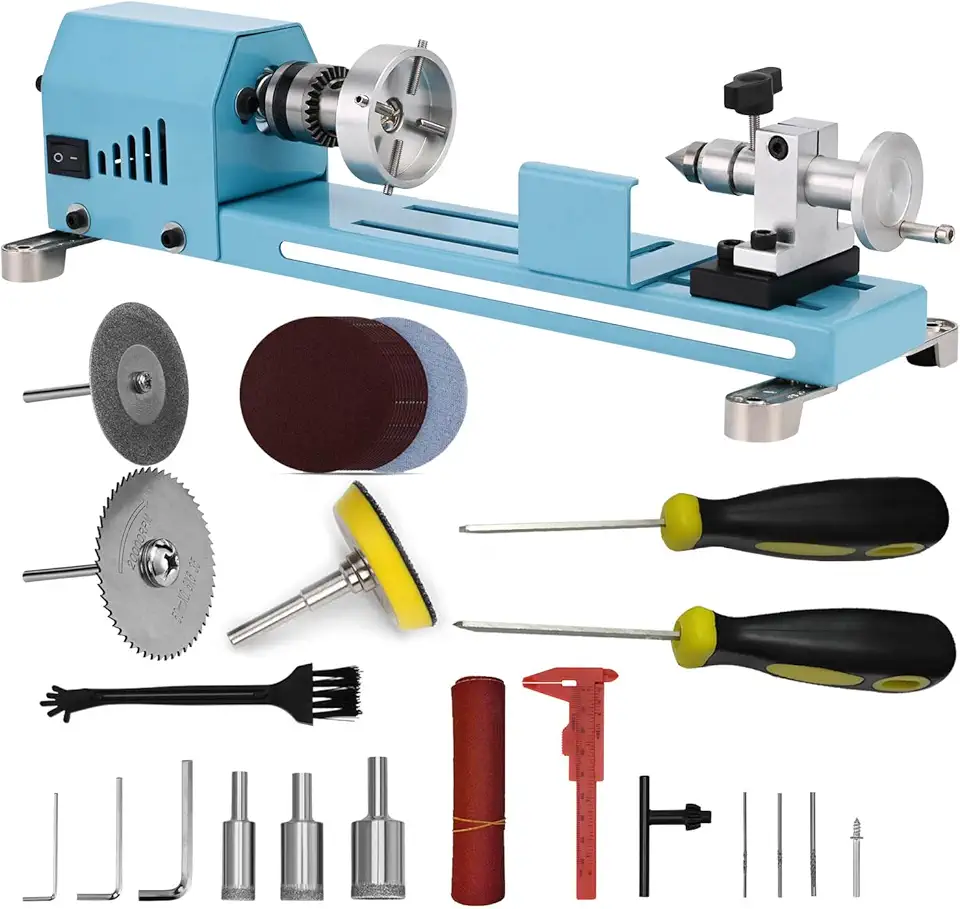

Best for beginners: Compact multi-purpose mini lathe

A multi-purpose mini lathe can be a practical first step if you want to try turning, polishing, and small shaping tasks without buying separate machines. The built-in starter kit approach saves time, but keep passes light and focus on setup accuracy to get clean results.

Compact Multi-Purpose Mini Lathe

- Versatile for cutting, grinding, polishing, and light milling tasks

- Includes a professional tool set to start projects right away

- Compact desktop footprint fits small workshops and benches

- Easy to set up and operate for hobbyists and beginners

- Good balance of power and control for multi material use

Best value mini wood lathe: WM101A-Plus

For pens, small handles, and compact spindle work, a small DC wood lathe with variable speed gives steady control at a low entry cost. Pair it with straight-grained turning blanks so your early projects cut cleanly; wood turning blanks can help you choose species and sizes that behave well on small machines.

WM101A-Plus Mini Wood Lathe

- 24V DC 96W motor delivers steady torque for woodturning tasks

- Infinitely variable speed control for precise shaping and finishing

- Comes with wood turning tool kit suited for small projects

- Small benchtop design saves workspace while remaining stable

- Ideal for DIY woodworkers and small professional jobs

High-power pick: VEVOR 8×14 metal lathe

An 8×14 class mini lathe machine gives more swing for larger diameters and a bit more muscle for tougher materials than many 7-inch models. It’s a better match for frequent metalwork where rigidity and torque matter, especially when you add sharper tooling and dial in conservative feeds.

VEVOR 8 inch x 14 inch Metal Lathe

- Powerful 650W motor with variable speed up to 2250 RPM for metalworking

- 8 inch by 14 inch capacity handles a wide range of turning jobs

- Built for precision with rigid construction and smooth motion

- Suitable for milling, facing, and threading with proper tooling

- Good choice for serious hobbyists and light industrial use

Best mini wood lathe: VEVOR 2.76×6.3

This style of compact mini wood lathe works well for tiny parts and detail shaping where you want quick speed changes and a small footprint. Expect best results when you keep tools sharp, limit overhang, and sand at controlled RPM rather than pressing hard.

VEVOR 2.76 inch x 6.3 inch Mini Wood Lathe

- Compact work area size ideal for small turnings and drills

- 24V DC 96W motor with seven selectable speeds for versatility

- Wide RPM range supports fine detail and faster removal

- Includes accessories for milling and rotary tasks

- Great for DIY woodworking and hobby projects

Precision hobby lathe: All-metal miniature model

A small all-metal miniature lathe with very high top speed is aimed at fine craft parts rather than heavy cutting. Use it for tiny bushings, model components, and soft metals where small tools and gentle passes beat raw horsepower.

All Metal Miniature Hobby Lathe

- All metal construction for durability and long life

- High speed up to 20000 RPM for fine small part work

- Low power 36W design suited to delicate hobby tasks

- Compact and didactical design ideal for learning and demonstrations

- Great for miniature metalwork and craft projects

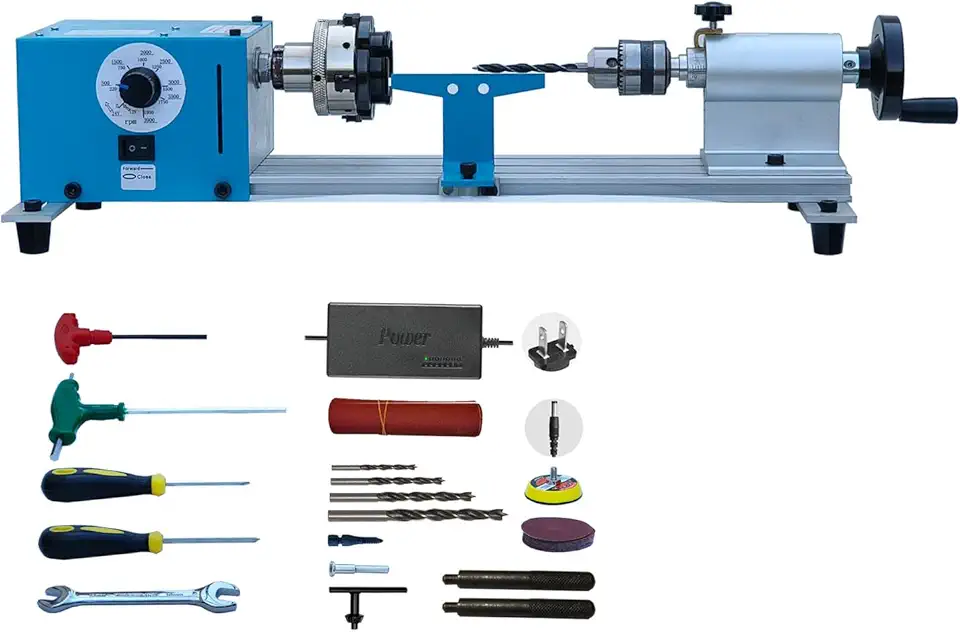

Extended capacity: 2.5×7.5 mini lathe with drill

If you want turning plus occasional drilling support in one compact footprint, this extended-capacity style can cover basic shop tasks. Treat drilling as a light-duty feature and focus on centering, clamping, and low feed pressure for clean holes.

Mini Lathe 2.5 inch x 7.5 inch with Drill Support

- Extended processing diameter and length for slightly larger small parts

- Supports drilling in addition to turning for added versatility

- Compact desktop design for limited workspace areas

- Suitable for cutting, polishing, and finishing tasks

- Easy to assemble and use for hobby projects

Mini lathe comparison snapshots

Use these snapshots to narrow your options by capacity class, then compare the “deal-breaker” specs like spindle bore, taper sizes, and tool compatibility. This approach keeps you from buying a machine that looks good on paper but blocks your common jobs.

7×14 benchtop lathe class

A 7×14 benchtop lathe is the classic entry point for hobby metalwork: enough swing for small diameters and enough bed length for short shafts. Plan on using sharp HSS or carbide inserts, and keep cuts light until you learn how your machine responds to tool pressure.

8×14 high-power class

An 8×14 class machine gives more room for chuck clearance and larger work, and it often comes with a heavier base that cuts vibration. If you’ll face steel often, pick the stronger motor option and commit to a solid bench because added power without stability still causes chatter.

Mini wood lathe class

Mini wood lathes shine for pens, small finials, knobs, and compact bowls, and they reward sharp tools and clean grain. If you’re still building your tool set, review common lathe tools so you buy the few chisels that cover most tasks; see lathe tools for a simple breakdown.

Hobby precision class

Hobby precision mini lathes focus on small parts where finish and repeatability beat removal rate. You’ll get the best outcome by using quality measuring tools and practicing consistent cuts, then checking your work often for taper or runout.

| Class | Typical swing | Typical centers | Typical motor | Good fit |

|---|---|---|---|---|

| 7×14 benchtop | 7″ | 14–16″ | 550–750W | General small metal parts |

| 8×14 high-power | 8″ | 14–20″ | 650–1000W | Frequent metal turning |

| Mini wood | 2.76–8″ | 6–12″ | 96W DC | Pens, small spindles |

| Hobby precision | 7–9″ | 16–18″ | 36–500W | Fine craft components |

Tips for using mini lathes safely

Mini machines still demand full-size safety habits because rotating work can grab sleeves, hair, and gloves fast. Build a simple routine—check clamping, set speed, stand out of the line of fire—so you reduce risk while making better finishes.

Speed by material

Start slow, then increase speed once the work runs true and cuts smoothly: steel often lives around 100–500 RPM on mini lathes, while wood can run 2000+ RPM depending on diameter and balance. If you’re unsure, pick the lower RPM, take a light pass, and watch for vibration before speeding up.

Setup stability

Stability starts at the bench: bolt the lathe down, level it, and add mass under the bench if it flexes. For longer stock, use tailstock support or a steady rest so the work doesn’t whip and cause chatter or unsafe vibration.

Maintenance basics

Wipe ways after each session, keep lead screws lightly lubricated, and clear chips so they don’t get crushed into sliding surfaces. Sharp tools lower cutting forces, so plan regular sharpening; a simple sharpening stone guide can help you keep edges consistent at home: sharpening stone.

For a broader overview of mini lathe pros, limits, and common feature ranges, see best mini lathe as a quick cross-check against the specs you’re shopping.

Useful upgrades

Spend on upgrades that improve workholding and measurement before cosmetic add-ons. A better live center, a 4-jaw chuck, a dial indicator, and improved lighting often raise accuracy more than a larger motor when your real limit is setup quality.

FAQs

What Can I Make With A Mini Lathe And What Materials Can It Handle?

A mini lathe can make small turned items like pens, bowls, bushings, shafts, and model components, and it can handle wood, plastics, brass, aluminum, and mild steel with proper tooling.

Harder steels and large diameters may be beyond many models; expect lighter cuts and use hardened tooling. Start with wood and softer metals and upgrade tooling and rigidity as you advance.

Which Mini Lathe Size/Specs Should I Choose (7×10 Vs 7×12 Vs 9×20)?

Choose a mini lathe by the largest workpiece you plan to turn: 7×10 models suit very small projects, 7×12 models handle slightly longer pieces, and 9×20 models offer greater diameter, length capacity, rigidity, and power for metalwork.

Also consider motor horsepower, spindle bore, bed quality, and available accessories over the model label when deciding.

Can A Mini Lathe Turn Steel And How Do I Improve Performance/Accuracy For Tougher Materials?

Yes, many mini lathes can turn mild steel when using carbide or sharp high-speed steel tooling with light cuts and reduced speeds.

Improve performance and accuracy by using rigid setups, a steady rest or tailstock support, proper feeds and speeds, sharp inserts, and alignment checks. Consider upgrading the toolpost, adding a digital readout, and improving motor control for tougher work.

What Are The Essential Accessories And Upgrades I Should Buy For A Mini Lathe?

Essential accessories are quality cutting tools (carbide and HSS), a good four-jaw chuck, live and dead centers, a steady rest, quick-change toolpost or toolholder, and a drill chuck or collet set.

Useful upgrades include a digital readout, splash guard, improved motor controller, and higher-quality ways or leadscrew; prioritize safety gear, measuring tools, and items that increase rigidity for better results.