CNC Router: 7 Models That Cut Costs

Want a CNC router that cuts costs without hurting results? This guide compares seven popular models. You’ll find options for hobbyists and small shops. Each pick shows the work area, spindle power, and where it shines. I call out low-cost features that really make a difference. Keep reading to find a wood CNC machine that fits your needs and budget.

Table of Contents

A cnc router helps you cut, carve, and engrave parts with repeatable accuracy using a computer and G-code. This guide explains budget-friendly features, smart upgrades, and seven popular machines so you can pick the right cnc router machine for wood and mixed materials.

CNC Router Basics and Cost-Saving Features

What a CNC router does

A cnc router uses stepper motors to move a spinning cutter across X, Y, and Z axes while the controller reads G-code. You can use it as a wood cnc machine for signs, inlays, joinery templates, relief carving, or you can mill plastics, acrylic, PCB, and even light metals depending on rigidity and spindle power.

Most beginner-friendly machines run GRBL firmware and connect by USB, letting you jog axes, set a work zero, then run a job with a repeatable toolpath. That repeatability is what makes a woodworking cnc machine useful: once feeds, speeds, and workholding are dialed in, you can re-run the same job with consistent results.

Materials for wood CNC machine work

For clean results, pick stable sheet goods before moving to tricky hardwoods. Baltic birch stays flatter than many construction panels, so it’s a strong baseline for a cnc machine wood setup; see Baltic birch plywood for what to look for when buying.

MDF is beginner-friendly because it machines evenly, but it produces very fine dust, so use a brush shoe or vacuum and wear a respirator. If you’re choosing MDF for paint-grade signs, review black MDF to decide when it’s worth paying extra for a cleaner edge and better surface.

Hardwoods like maple and walnut can look great, but grain direction, knots, and moisture swing can cause tear-out or warping. Start with shallow passes, sharp bits, and simple toolpaths, then move to tougher woods once your cnc wood router settings are stable.

GRBL control and free software

GRBL is a popular open-source controller standard on many hobby machines, which keeps costs down while staying compatible with common senders. Many makers run free or low-cost tools for CAM and control, then send G-code to the cnc router machine over USB or via an offline pendant.

If you want a quick overview of setup and first cuts, this video walkthrough can help you recognize the common GRBL workflow steps like homing, setting zero, and running a job on a desktop machine.

Keep your first jobs simple: engrave text, cut softwood templates, and practice surfacing your spoilboard. That dialing-in phase lowers scrap and makes your wood cnc machine feel predictable.

Budget features that cut costs

Budget machines save money by using smaller frames and simpler electronics, but the best ones spend where it matters: motion accuracy and stiffness. Look for lead screws or linear rails on at least the X-axis and Y-axis, since they reduce backlash and chatter that quickly ruins edges in wood.

- Offline controllers reduce the need for a dedicated workshop PC and can shorten setup time.

- All-metal frames cut vibration versus thin acrylic or flexy plates, improving finish quality.

- Linear rails keep motion smooth under load, which matters when cutting plywood or hardwood.

- Dust control (even a basic shoe) saves bits and bearings by keeping chips out of moving parts.

- Upgrade paths like stronger spindles or better stepper drivers extend useful life without replacing the machine.

Pricing varies a lot by class: small 3018-style kits can sit under $500, while larger hobby machines often land closer to $500–$1,000 depending on spindle and motion parts. For a quick market snapshot of budget CNC options and what features show up at each tier, reference best budget CNC machines.

Why Budget CNC Routers Make Sense

Best use cases

A budget cnc router makes sense if you want repeatable parts, clean engraving, or small-batch production without paying for a large cabinet machine. It’s a solid fit for makers cutting jigs, coasters, nameplates, drawer organizers, and small signs, or for small shops adding CNC to support hand-tool work.

These machines also work well for learning CAD/CAM on real hardware because mistakes are cheaper and the footprint is smaller. Pair your CNC work with simple workholding methods and the right clamps; this guide to types of clamps helps you pick options that won’t collide with the spindle during a toolpath.

Accuracy and rigidity upgrades

Accuracy comes from machine stiffness, low backlash, and consistent workholding. If your cuts show waviness or fuzzy edges, focus on rigidity upgrades first: tighten frame bolts, reduce gantry flex, and switch to a sharp bit with the right flute count for the material.

Lead screws and closed-loop motors can help by reducing lost motion and avoiding missed steps on aggressive cuts. If you want a technical overview of how CNC routers are built and how pro machines differ from hobby models, STYLECNC’s overview offers helpful context: CNC router guide.

Spindle power for wood

Spindle power affects feed rates, depth of cut, and how often you burn wood. A 300W spindle can engrave and do light routing, but a 400–500W class spindle (or trim router) usually cuts wood faster with fewer passes, especially in plywood and hardwood.

Power isn’t everything: a stronger spindle on a flexible frame can still chatter. Balance spindle upgrades with better rails, a stiffer gantry, and a flat spoilboard so your cnc machine wood jobs stay consistent across the full work area.

Genmitsu 3018-PRO Desktop CNC Router

Genmitsu 3018-PRO Desktop CNC Router

- Compact 3-axis desktop CNC for hobby projects

- Offline controller for standalone operation

- Cuts and engraves plastic, acrylic, PCB and wood

- 300×180×45mm working area for small parts

- GRBL-compatible and beginner-friendly setup

Work area and best projects

The 3018-PRO’s compact footprint fits small benches and apartments, and its work area suits engravings, PCB isolation milling, and small wooden badges. As an entry wood cnc machine, it’s best for shallow passes in softwood, thin plywood, and light acrylic where low cutting forces keep deflection down.

Project ideas that match the size: control panel labels, tool holders, simple coasters, lightning bolt inlays, and small boxes with engraved lids. Keep stock flat and supported so the cnc router doesn’t cut deeper at the edges.

Strengths and tradeoffs

The big wins are cost, GRBL compatibility, and the offline controller for running jobs without a PC connected full-time. The main tradeoff is limited stiffness and Z travel, which means you’ll use conservative feeds and shallow depths to get clean results from this cnc wood router.

To stretch performance, focus on basics: tramming (squaring) the spindle, surfacing the spoilboard, and using sharp bits. Those steps often improve finish quality more than chasing aggressive feeds on a small cnc router machine.

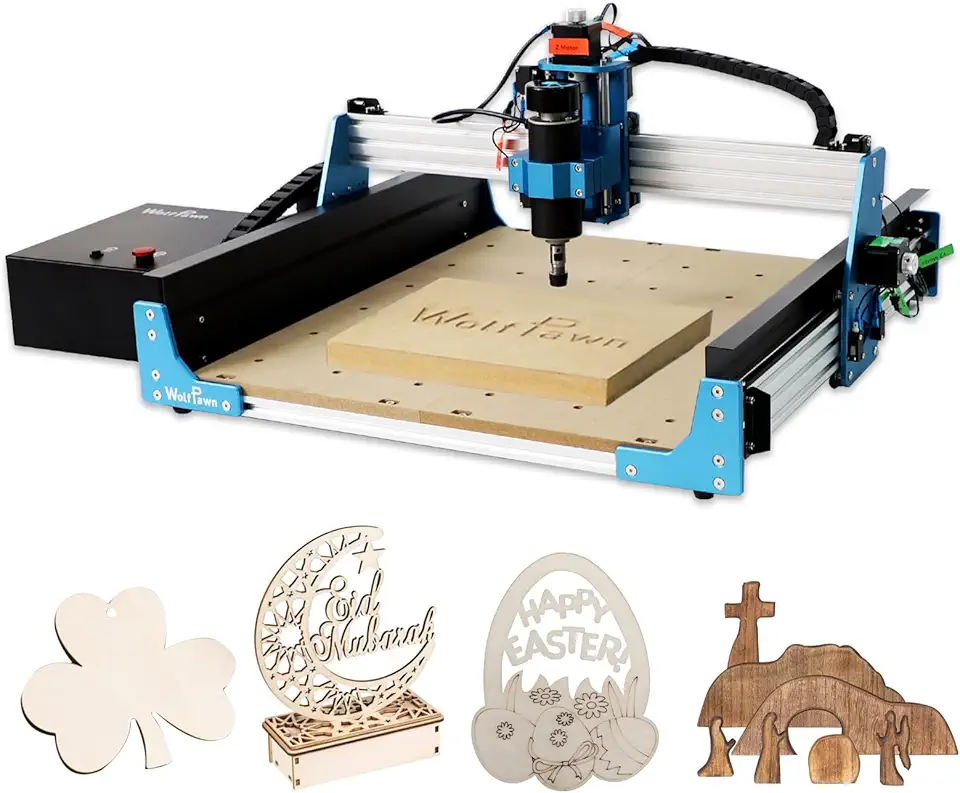

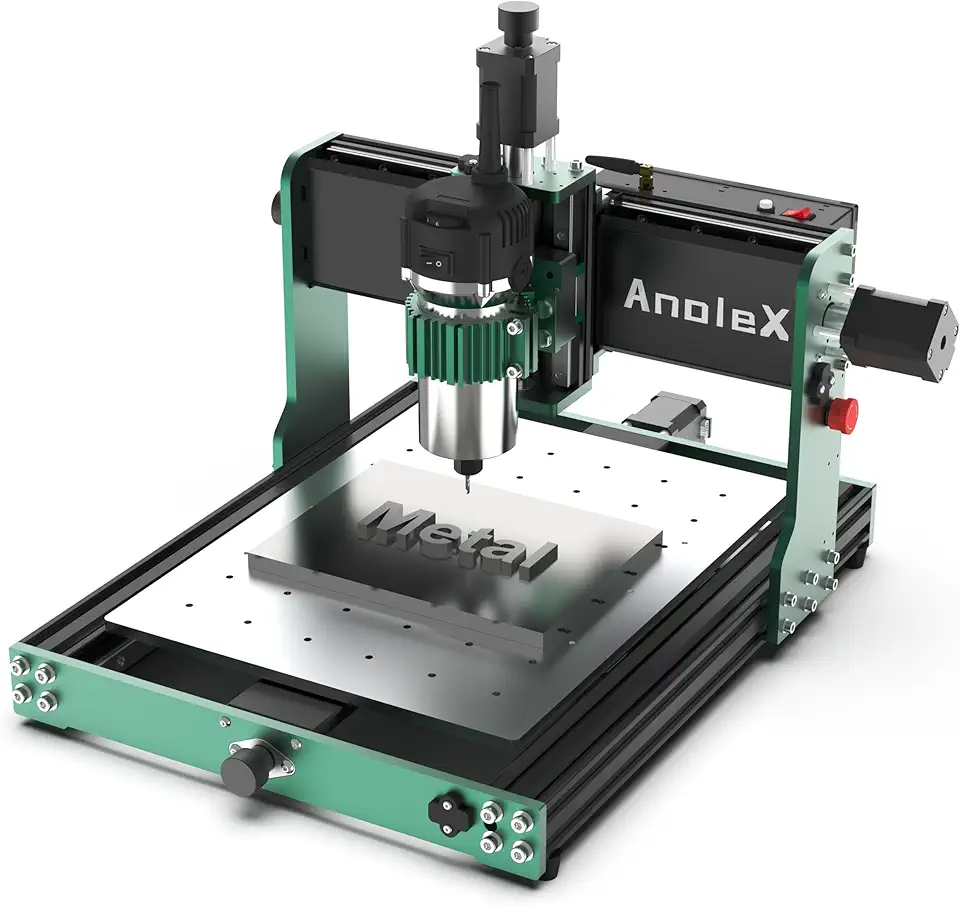

4040 PRO All-Metal 3-Axis CNC Router

4040 PRO All-Metal 3-Axis CNC Router

- All-metal 3-axis CNC for heavier-duty hobby work

- 500W trimmer spindle for faster cutting

- Linear rail and steel-wheel drive for smooth accuracy

- 15.75×15.75×2.95in work area for larger projects

- GRBL control for familiar CNC software compatibility

Linear rails and rigidity

Moving up to a 4040 format usually means a stiffer frame and more usable work area for signs, trays, and cabinet templates. Linear rails help reduce play under load, which matters when your woodworking cnc machine starts pushing larger bits through plywood or hardwood.

If you plan to cut sheet goods, confirm your actual panel thickness and keep your CAM toolpaths realistic for your material. This reference on plywood dimensions helps you avoid cutting air or leaving tabs too thick because the sheet wasn’t the nominal size.

500W spindle benefits

A 500W trim-router-style spindle can increase feed rates in wood and reduce the need for many shallow passes. That can shorten job time on a cnc machine wood workflow, especially on pockets and profile cuts where chip clearing matters.

Plan for noise and dust: higher power pushes more chips, so use a dust shoe and a shop vac or extractor. Cleaner chip evacuation helps prevent re-cutting chips, which is a common cause of burning on a cnc router.

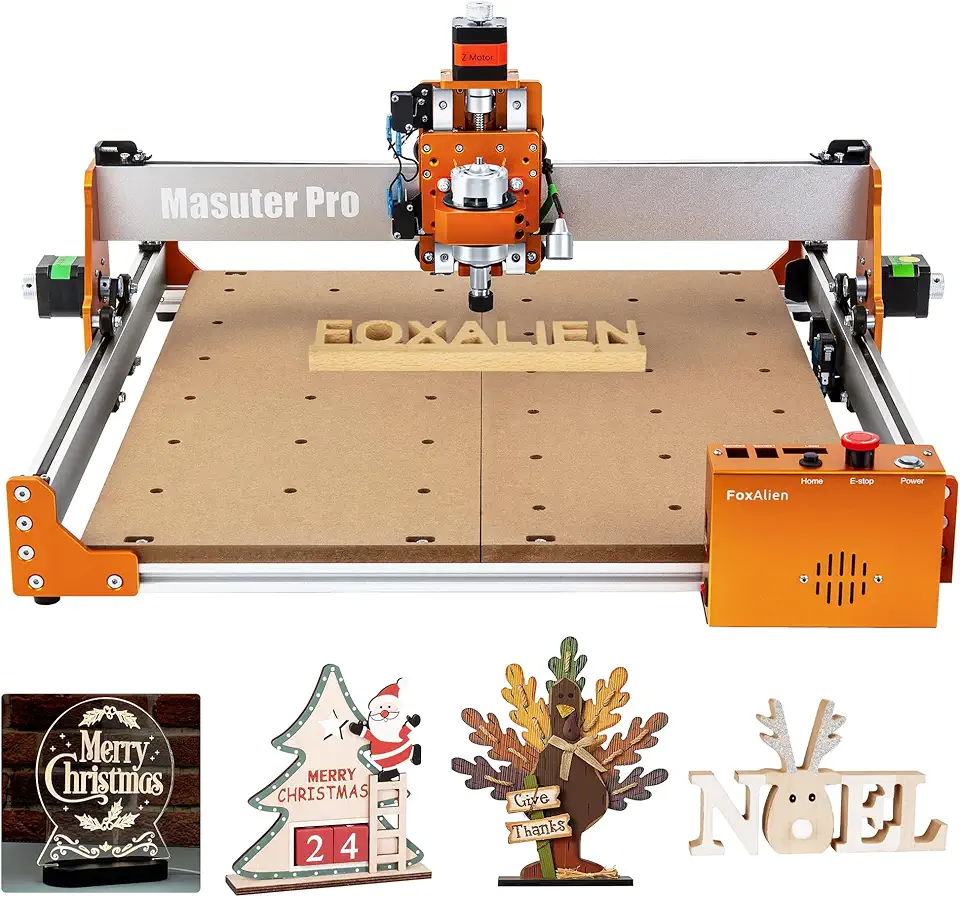

FoxAlien Master Pro 3-Axis CNC

FoxAlien Master Pro 3-Axis CNC

- Durable all-metal 3-axis CNC for hobbyists

- Designed for wood, acrylic, MDF and nylon carving

- Stiff frame reduces vibration for cleaner cuts

- User-friendly controls for newcomers to CNC

- Ideal for detailed routing and milling projects

Clean cuts and low vibration

Vibration is the enemy of clean edges, tight-fitting joints, and readable text. A stiffer machine like this can help your cnc wood router produce smoother walls and less fuzz in plywood and MDF when feeds and speeds are set correctly.

Use the stiffness to your advantage by switching from “many shallow passes” to “reasonable passes” while staying within the machine’s comfort zone. The goal is stable chips and consistent sound, not the fastest possible cut on your cnc router machine.

Detail work for cnc wood router

Detail carving depends on bit selection and toolpath strategy more than raw power. For fine text and relief carving, use a sharp V-bit or small ball nose, keep step-over conservative, and run a finishing pass so the wood cnc machine doesn’t leave scallops.

For painted signs, run a light “spring pass” at the final depth to clean up minor deflection. That extra pass can make small lettering look crisp on a cnc machine wood setup.

Genmitsu 4040-PRO Lead Screw CNC Router

Genmitsu 4040-PRO Lead Screw CNC Router

- 4040-PRO lead-screw CNC built for precise milling

- GRBL-compatible control for easy software use

- Cuts and mills metal, acrylic and wood materials

- 15.7×15.7×3.1in work area for medium projects

- Lead screw drive reduces backlash for accurate finishes

Lead screw precision and backlash

Lead screws can reduce backlash compared to basic belt drives, which helps when pockets need square corners and parts must fit without hand trimming. With less lost motion, your cnc router can hit consistent dimensions across repeated runs, which matters for small-batch products.

Backlash control also shows up in engraving quality. If your letters look slightly “wobbly,” tightening motion parts and using lead-screw motion can make your woodworking cnc machine output look sharper.

Mixed-material capability

A medium-format machine with lead screws can handle wood all day and still take on acrylic, plastics, and light aluminum jobs with the right bits and shallow passes. That flexibility is useful if your cnc router machine needs to make jigs, brackets, and fixture plates alongside wood projects.

Use stable plywood for jigs and fixtures, and choose the right grade to reduce voids that can break small cutters. This guide to plywood grades helps you pick panels that machine cleanly on a cnc machine wood workflow.

FoxAlien Masuter 3S with Closed-Loop NEMA23

FoxAlien Masuter 3S with Closed-Loop NEMA23

- Masuter 3S with closed-loop NEMA 23 for reliable motion

- 400W spindle delivers strong cutting performance

- Handles wood, acrylic and light aluminum work

- Improved position accuracy and reduced missed steps

- Built for precise carving and cutting tasks

Closed-loop reliability

Closed-loop steppers add feedback so the machine can correct position errors rather than silently losing steps. That’s a big deal for long jobs where a single missed step can ruin a sign, since your cnc wood router might not show the mistake until the final contour pass.

Reliability also improves when you keep drag chains tidy, reduce cable strain, and use dust control so bearings don’t grind down over time. Those habits help your cnc router machine stay accurate without constant re-tuning.

400W spindle for cnc machine wood

A 400W spindle is a practical middle ground for wood: it supports decent feed rates while keeping overall cost and complexity lower than a full-size trim router. Pair it with good chip evacuation and you’ll get cleaner edges on your cnc machine wood projects.

Start with conservative depth of cut, then increase feed before increasing depth. That approach reduces heat and burning, which is often the first issue new wood cnc machine owners hit.

Twotrees TTC450 Pro 3-Axis CNC with Touchscreen

Twotrees TTC450 Pro 3-Axis CNC with Touchscreen

- TTC450 Pro with NEMA 57 closed-loop motors for stable motion

- Intuitive 3.5in touchscreen for on-machine control

- Upgraded mechanics for smoother engraving and milling

- Handles wood, acrylic and light aluminum projects

- Built for faster setup and precise cuts

Touchscreen workflow

A touchscreen can reduce friction in daily use: jogging, setting work zero, and starting jobs are easier when you don’t rely on a laptop balanced near dust and chips. That smoother workflow helps new owners run more test cuts, which builds confidence with a cnc router faster than overthinking settings.

Even with on-machine control, keep a simple checklist: verify bit tightness, confirm the right file, and do an “air cut” above the work to check boundaries. Those habits prevent common crashes on a cnc router machine.

Value vs mid-tier pricing

Mid-tier machines often add the parts that matter most for real woodworking: stronger motors, better motion components, and more usable work area. If your goal is selling products or running longer jobs, paying for stability can be cheaper than wasting wood, bits, and time on failed cuts.

Budget pricing also shifts with supply and bundles, so compare what’s included (spindle, controller, limit switches, dust shoe) rather than price alone. Omni CNC’s roundup provides more buying context for woodworking cnc machine shoppers: best CNC router for woodworking.

3030-Evo Max 800W Heavy-Duty CNC Router

3030-Evo Max 800W Heavy-Duty CNC Router

- High-power CNC with 800W router for heavy cutting

- Dual steel linear guides for maximum rigidity

- All-metal XYZ frame built for tough materials

- Cuts aluminum, brass, stainless steel and plastics

- Suited for professional-grade milling and fabrication

800W power and rigidity

An 800W spindle paired with a stiff frame supports heavier cutting and tougher materials, which reduces cycle time on thick hardwood and dense sheet goods. High power only pays off if the machine stays rigid, so dual linear guides and an all-metal frame can help your cnc router keep accuracy under load.

Expect higher demands for workholding and a solid base. A stable bench reduces chatter, so set your machine on a flat, heavy surface; this guide on woodworking workbenches can help you plan a setup that won’t shake during long jobs.

Best for tough materials

This class is a better match if you want one cnc router machine for wood plus regular plastics and light-to-moderate metal projects. You’ll still need the right tooling, chip clearing, and conservative passes in metal, but the added stiffness makes those jobs more realistic than on a small desktop unit.

Use it for hardwood joinery parts, thick sign blanks, fixture plates, and small brackets, then tune feeds by listening for steady cutting rather than squealing. That sound-based feedback helps keep your cnc machine wood work clean while protecting bits and bearings.

| Model type | Work area example | Spindle power | Price range (typical) | Best for |

|---|---|---|---|---|

| 3018 desktop | 300×180×45mm | 300–500W | $200–$500 | Small wood engraving and light routing |

| 4040 mid-size | 15.7×15.7×3.1in | 400–500W | $500–$1,000 | Most hobby woodworking CNC machine projects |

| Heavy-duty | Varies | 800W | Under $1,000 | Wood plus tougher mixed materials |

Pick a CNC router by matching stiffness, work area, and spindle power to the cuts you’ll run most often, then buy the machine that wastes the least time on setup and rework.

Shop-floor rule of thumb

FAQs

What Is A CNC Router And How Does It Work?

A CNC router is a computer-controlled machine that cuts and shapes materials using a rotating spindle guided by digital instructions. The design is created in CAD software, converted to toolpaths in CAM, and executed as G-code that moves the machine accurately along multiple axes for cutting, engraving, and carving.

How Much Does A CNC Router Cost For Hobbyists And Small Shops?

CNC router prices depend on size, rigidity, spindle power, and features. Hobby desktop machines usually cost between $200 and $1,000, while prosumer models range from $1,000 to $5,000. Small-shop production routers typically start around $5,000 and can exceed $30,000, plus added costs for tooling, software, and accessories.

What Materials Can A CNC Router Cut — Can Hobby Routers Handle Aluminum?

CNC routers commonly cut wood, MDF, plywood, plastics, foam, composites, and soft metals. Hobby routers can cut aluminum when using proper tooling, rigid workholding, light passes, and correct speeds and feeds. Thicker aluminum or harder metals are better handled by a CNC mill or heavy-duty industrial router.

How Do I Maintain, Calibrate, And Troubleshoot A CNC Router For Accurate Cuts?

Accurate cuts require regular cleaning, lubrication, and inspection of belts, bearings, and fasteners. Calibration involves tramming the spindle, squaring the gantry, and verifying motion settings with test cuts. Common issues like chatter or poor finish are usually solved by adjusting feeds, depths of cut, tooling sharpness, and workholding.