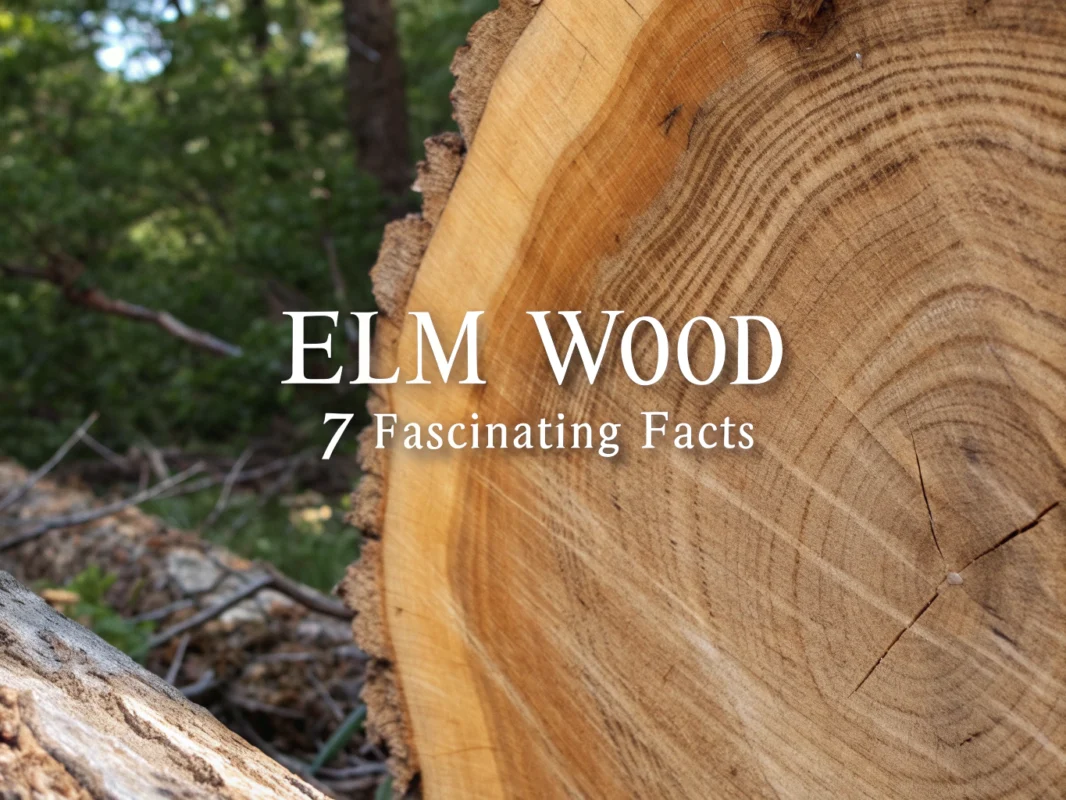

Did you know that elm wood has been a favorite for centuries due to its distinctive grain and strength? With its unique properties, elm is not only visually appealing but also practical for a variety of applications. Whether you’re a fan of woodworking or just curious about this versatile material, there’s much to learn about elm wood.

Table of Contents

Elm wood stands out among hardwoods for its distinctive interlocked grain patterns and exceptional bending properties, making it a prized material for furniture makers and craftspeople. With a mean density of around 560 kg/m³ and excellent shock resistance, this versatile timber offers unique characteristics that set it apart from other common hardwoods.

Introduction to Elm Wood Species and Characteristics

Elm Species Overview

Elm wood comes from various Ulmus species, including red elm (Ulmus rubra), English elm (Ulmus procera), and wych elm. The heartwood typically displays reddish brown to dark brown coloring, while the sapwood ranges from grayish white to light brown. According to Logie Timber, elm maintains a mean density around 560 kg/m³, contributing to its moderate weight and excellent stability characteristics.

Different elm species offer varying properties, but all share the characteristic interlocked grain structure that makes this wood so distinctive. Red elm, also known as slippery elm, tends to be slightly softer than its English counterpart. English elm provides superior strength properties, while wych elm offers excellent workability for detailed projects.

Distinctive Grain and Texture

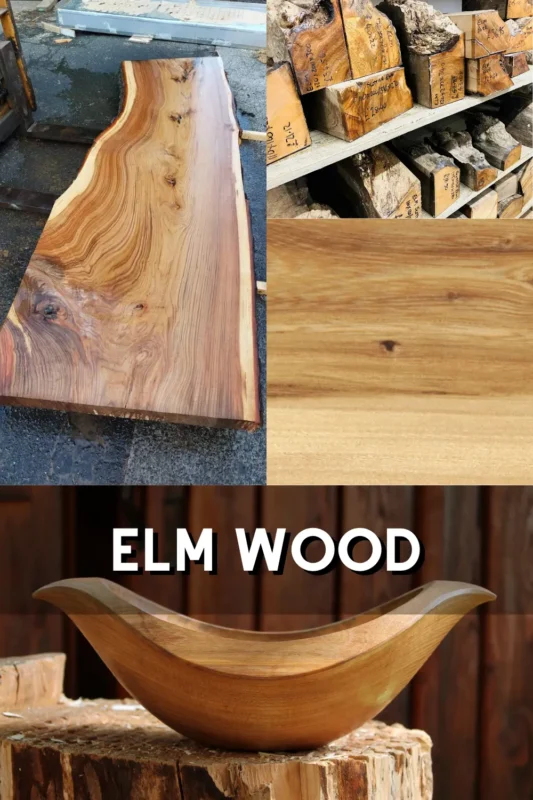

The most striking feature of elm wood is its interlocked and twisted grain patterns that create stunning visual effects. This grain structure produces a coarse texture with remarkable visual appeal that makes each piece unique. Hardwood Info notes that burr elm is particularly valued for its decorative properties, featuring swirling patterns and color variations including greens and purples.

The grain’s complexity creates what woodworkers call “cat paw” figuring in premium specimens. This natural characteristic makes elm wood highly sought after for statement furniture pieces and decorative applications where visual impact is important.

Mechanical Properties and Strength Performance

Physical Properties

Elm wood is classified as moderately heavy, hard, and stiff with exceptional bending and shock resistance capabilities. The interlocked grain structure that creates its beautiful appearance also makes it extremely difficult to split, which can be both an advantage and challenge depending on the application. Hardwood Info confirms that this resistance to splitting makes elm excellent for applications requiring high shock resistance.

The wood’s density varies within a range of ±20% from the mean, but consistently provides reliable structural performance. This variation allows woodworkers to select pieces based on specific project requirements, whether they need maximum strength or prefer easier workability.

Durability and Moisture Characteristics

Elm wood receives a classification of “slightly durable” for natural durability, making it suitable for interior applications without additional treatment. The moisture movement is rated as medium, meaning it responds moderately to humidity changes. Logie Timber reports that elm dries well with minimal degrade and shows little movement in service once properly seasoned.

Water resistance properties made elm historically valuable for water mains and marine applications. This natural resistance to moisture damage continues to make it an excellent choice for furniture and millwork in varying humidity conditions.

Workability and Finishing Capabilities

Machining and Tool Performance

Elm wood works fairly easily with proper techniques and sharp tools. It nails, screws, and glues exceptionally well, making it ideal for both traditional joinery and modern construction methods. The interlocked grain can cause moderate tool blunting, so maintaining sharp cutters is important for clean results.

Woodworkers should plan for grain reversal during machining, particularly when planing or jointing. This characteristic requires attention to feed direction and cutting angles to achieve smooth surfaces without tearout.

Steam Bending and Finishing

One of elm’s most valuable properties is its superior steam bending capabilities. Woodworkly highlights that elm steams and bends easily, making it perfect for curved furniture components like chair legs and frames. This flexibility opens up design possibilities that would be difficult with less cooperative woods.

The wood takes stains, polish, and wax finishes exceptionally well, allowing for professional-quality results. It sands to a smooth finish and accepts both traditional and modern finishing materials without issues.

What Is Elm Wood Used For: Traditional and Modern Applications

Historical Applications

Elm’s water-resistant properties led to its use in historic water mains throughout English towns before widespread metal piping became available. Logie Timber documents this important historical application that took advantage of elm’s natural durability in wet conditions.

Traditional applications included furniture, paneling, caskets, and millwork where strength and shock resistance were valued. These historical uses established elm’s reputation as a reliable hardwood for demanding applications.

Contemporary Uses

Modern elm wood furniture includes tables, chairs, benches, bed frames, and cabinetry, all valued for their unique grain patterns and warm coloring. The wood’s distinctive appearance makes it particularly popular for statement pieces and custom furniture where visual impact matters.

Natural Grey Elm Lumber Board

- Perfect for crafting or DIY projects

- Kiln dried for stability and quality

- Smooth finish ready for painting or staining

- Durable and strong for long-lasting use

- Ideal size for easy handling and cutting

Decorative veneers and live-edge slabs represent growing markets for elm wood applications. WL West notes that musical instrument makers also prize elm for stringed instruments due to its attractive tonal qualities and workability.

Is Elm Wood Good Firewood? Burning Performance Analysis

Firewood Challenges

The interlocked grain that makes elm beautiful for furniture creates significant splitting difficulties when preparing firewood. Hardwood Info confirms that elm is hard to split due to its grain structure, making it more labor-intensive than straight-grained alternatives.

Water resistance can cause elm to retain moisture longer than other hardwoods, requiring extended seasoning time for acceptable burning performance. Proper drying becomes critical for anyone considering elm as firewood.

Comparison to Other Hardwoods

Is elm wood good to burn? While elm can be used as firewood if well-seasoned, it’s generally less preferred than oak or ash for heating purposes. The grain-related splitting difficulty makes processing challenging, and the wood’s value for furniture applications often makes it more economical to use for woodworking projects.

For those wondering “is elm wood good firewood,” the answer depends on availability and alternatives. If properly seasoned and you don’t mind the extra effort in splitting, elm can provide decent heat output, but other hardwoods typically offer better convenience and performance.

Design and Aesthetic Value in Furniture Applications

Visual Appeal Characteristics

Elm wood furniture showcases distinctive swirling and interlocked grain patterns that create natural artwork in every piece. Color variations including greens and purples add depth and character that can’t be replicated with stains or artificial techniques.

Premium specimens feature “cat paw” figuring that creates three-dimensional visual effects. This natural characteristic makes elm wood furniture pieces conversation starters and focal points in any room design.

Furniture and Interior Design Applications

Live-edge tables and statement pieces represent some of the most popular elm wood furniture applications. The wood’s resistance to splitting under stress makes it ideal for functional furniture that must withstand daily use while maintaining its visual appeal.

Rustic Live Edge Shelves

- Set of 2 for ample storage

- Solid elm wood for durability

- Invisible brackets for seamless appearance

- Adds natural rustic flair to rooms

- Perfect for displaying decor and essentials

Bold grain patterns make elm wood furniture perfect for rustic and contemporary designs alike. The wood’s excellent finishing potential allows it to work in both casual and formal settings, adapting to various design aesthetics.

Sustainability, Availability, and Market Considerations

Environmental Impact

Elm wood represents a sustainable hardwood choice when sourced from responsibly managed forests. Meinwood emphasizes that elm’s natural resistance to some fungal and insect attacks reduces the need for chemical treatments in many applications.

The development of disease-resistant “Resista” elm varieties supports future sustainability by protecting elm stands from Dutch elm disease. These efforts help maintain elm as a viable timber resource for future generations.

Market Availability and Pricing

Elm wood is readily available in North America, though pricing can be expensive, particularly for burr elm and high-figure slabs. Logie Timber notes that European supply has been historically affected by Dutch elm disease, influencing market dynamics and pricing.

The wood’s popularity for furniture and decorative applications keeps demand steady, making it a valuable investment for both woodworkers and furniture buyers. Quality elm lumber commands premium prices due to its unique characteristics and limited availability of premium grades.

Elm Wood Dining Bench

- Elegant addition to any room

- Sturdy and long-lasting design

- Comfortable footrest height

- Ideal for dining and entryways

- Enhances any space with a natural look

Practical Buying and Working Tips

Selection and Preparation

Choose kiln-dried elm lumber for maximum stability and reduced movement during construction. Boards with stable moisture content will provide better results and fewer surprises during the building process.

Select pieces based on your project’s grain requirements – highly figured pieces work best for decorative applications, while straighter grain sections may be preferable for structural components. For more woodworking insights and project ideas, check out our woodworking blog for detailed guides and techniques.

Working Techniques

Pre-drill holes for screws to prevent splitting, especially near board edges where the interlocked grain can cause unexpected breaks. Use sharp cutters and proper feed rates to achieve clean cuts without tearout or burning.

Take advantage of elm’s steam-bending capabilities for curved components in furniture projects. This natural flexibility allows for design possibilities that would require lamination or complex joinery with other hardwoods, making elm an excellent choice for both traditional and contemporary furniture designs.

FAQs

What Are The Characteristics Of Elm Wood?

Elm wood is known for its interlocking grain pattern, which provides excellent resistance to splitting. It has a coarse texture and a beautiful, rustic appearance that is highly prized. The color ranges from pale cream to a deeper reddish-brown, which darkens with age.

Is Elm Wood Good For Furniture?

Yes, elm wood is a great choice for furniture making because of its strength and flexibility. It can be easily bent and shaped, making it suitable for crafting a wide variety of furniture pieces. Additionally, its aesthetic appeal adds a natural charm to any room.

How Do You Care For Elm Wood Flooring?

To care for elm wood flooring, it’s important to keep it clean and dry. Regular sweeping and occasional damp mopping with a hardwood-friendly cleaner can help maintain its appearance. Avoid harsh chemicals or excess water to prevent damage to the wood.

What Are The Pros And Cons Of Using Elm Wood?

The pros of using elm wood include its durability, resistance to splitting, and attractive grain. However, it can be difficult to find, and the wood may warp if not properly dried. Its price can also be higher than other woods due to its desirability and limited supply.

How Does Elm Wood Compare To Oak Wood In Terms Of Durability?

Elm wood is durable and offers excellent resistance to wear and tear, similar to oak. However, oak is generally considered harder, which can make it more resistant to dents and scratches. Both woods have their unique characteristics, so the choice often depends on personal preference and specific use cases.