High Density Fiberboard (HDF board): 5 Best Picks

Ever wondered what makes high density fiberboard (HDF board) a top choice for many furniture and crafting projects? With its exceptional durability and smooth finish, it’s no surprise. This article highlights the best picks, helping you choose the right one for your needs.

Table of Contents

High density fiberboard represents a significant advancement in engineered wood technology, offering superior strength and durability compared to standard MDF through its high-pressure manufacturing process. This dense material has become the preferred choice for commercial flooring, premium cabinetry, and high-traffic applications where exceptional performance is required.

What is High Density Fiberboard? Definition and Key Characteristics

High density fiberboard is an engineered wood product created by compressing wood fibers under extreme pressure. This manufacturing process results in a board that’s significantly denser and harder than medium density fiberboard or standard chipboard materials.

Understanding HDF Construction and Composition

The construction process involves compressing recycled wood fibers under intense pressure, creating a material with density typically exceeding 50 lbs/ft³. This makes HDF considerably denser than standard MDF, which ranges from 30-50 lbs/ft³. The boards come in various thicknesses from as thin as 1.6mm up to 3/4″ or more, providing flexibility for different project requirements.

Key Attributes and Properties

- Exceptional durability and strength for heavy-duty applications

- Smooth surface finish that’s ideal for paint or veneer application

- Better resistance to wear compared to standard MDF

- Moderate moisture resistance when properly sealed

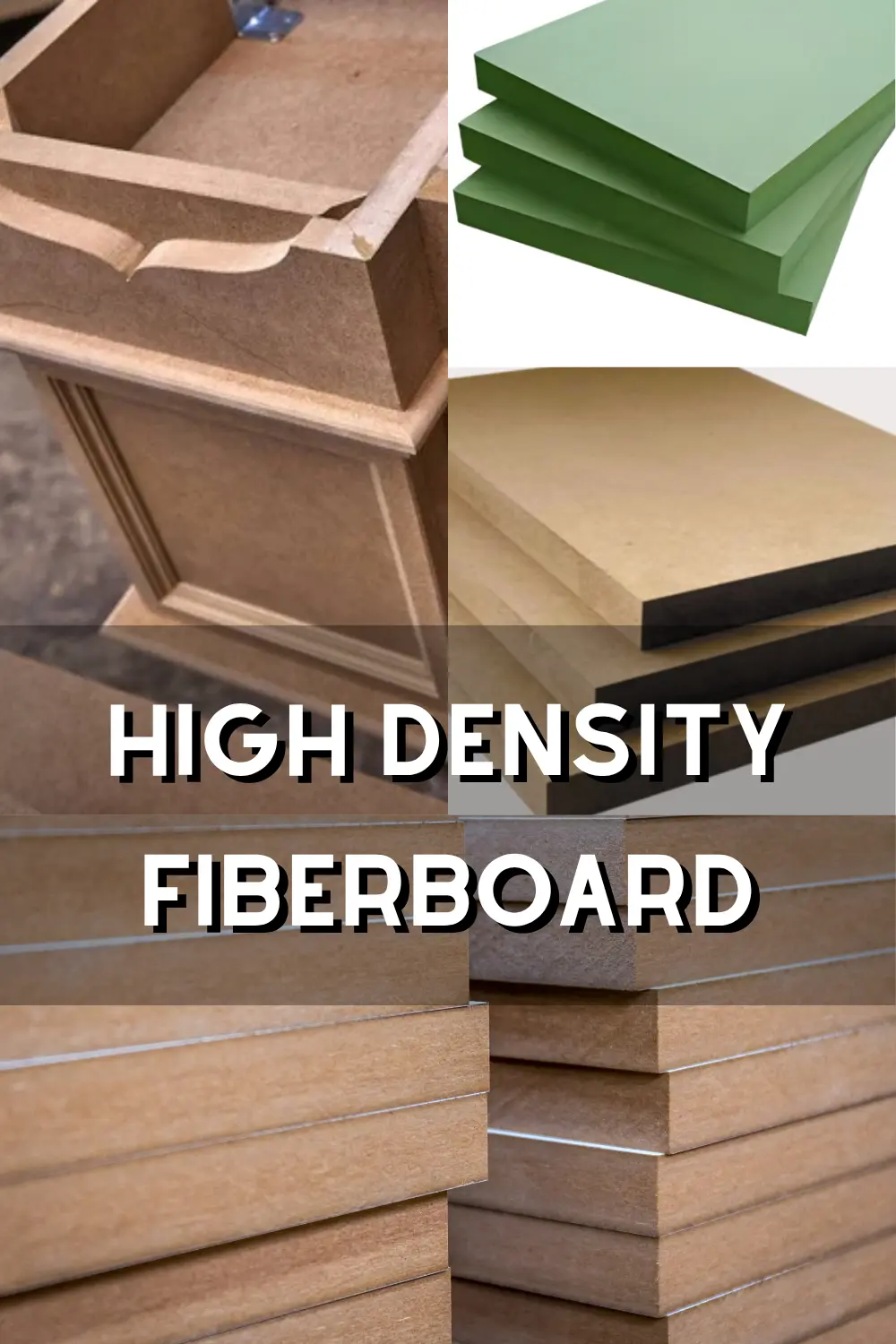

The tightly compressed surface allows for flawless finishing, making it an excellent choice for painting, laminating, or veneering projects. Unlike thin wood alternatives, HDF maintains structural integrity even in demanding applications.

Primary Applications

HDF finds its primary use in commercial flooring substrates, premium cabinetry, furniture construction, and door panels. The material’s superior strength makes it particularly suitable for high-traffic commercial environments where standard materials might fail.

Top 5 High Density Fiberboard Products for 2026

Here are the top-rated HDF products available for various applications:

CalPalmy 11 x 14 Multipurpose MDF Boards

- Smooth unfinished sides for easy customization

- Ideal for carpentry and crafting projects

- Durable 1/4 thickness for stability

- Sanded edges for a professional look

- Suitable for hobby crafts, interior design, and more

Officemate 5x9 Craft MDF Boards, 20PK

- Perfect size for small craft projects

- Medium density for solid performance

- Lightweight for easy handling

- Unfinished for customizable creativity

- Great value with 20 pieces per pack

DARENYI A3 MDF Craft Boards

- 4mm thickness perfect for detailed engraving

- Ideal canvas paper alternative

- Unfinished wood for custom painting

- Suitable for laser engraving tasks

- Economical choice for art projects

Wood Pegboard Set for Wall Displays

- Large 24x48 size for ample storage space

- High density for sturdy organization

- Includes mounting hardware

- Round holes for versatile storage solutions

- Perfect for garages, craft rooms, and workshops

Bright Creations MDF Chipboard Sheets

- 11x14 size suits various projects

- Thick 1/4 inch for sturdy creations

- Great for crafts and DIY endeavors

- Customizable hardboard for personal designs

- Durable and easy to work with

HDF vs. Other Engineered Wood Products: Complete Comparison

HDF vs. MDF (Medium Density Fiberboard)

The primary difference lies in density and strength. HDF’s higher density makes it more suitable for demanding applications like commercial flooring and premium furniture. MDF works well for interior elements with less structural requirements, while HDF excels in high-durability scenarios.

HDF vs. Plywood

Baltic birch and other plywood types generally offer better moisture resistance and structural strength for load-bearing applications. HDF provides a smoother surface finish, making it ideal for painting and high-end finishing work where surface quality matters most.

HDF vs. MFC (Melamine-Faced Chipboard)

According to Casta Cabinetry, HDF outperforms melamine-faced chipboard in structural rigidity and surface smoothness. This makes HDF the better choice for premium furniture applications where longevity and finish quality are priorities.

What to Consider When Choosing High Density Fiberboard

Application-Specific Requirements

Select thickness based on your project’s structural demands. Thicker HDF boards provide superior strength for heavy-duty applications, while thinner options work well for craft projects and decorative elements. Consider the load requirements and expected wear patterns.

Surface Quality and Finish Needs

- Choose sanded surfaces for optimal paint adherence

- Consider unsanded options for projects requiring texture

- Evaluate edge quality for visible applications

- Check compatibility with intended finishes

For detailed work requiring precision, look for boards with consistent surface quality that won’t require extensive preparation before finishing.

Environmental and Safety Factors

Prioritize boards meeting TSCA Title VI standards for formaldehyde emissions. Look for NAF (No Added Formaldehyde) options when air quality is a concern. FSC certification indicates sustainable sourcing practices, which is increasingly important for environmentally conscious projects.

Leading High Density Fiberboard Manufacturers and Brands

Major Global Manufacturers

Baier Floor identifies Kronospan as a leading manufacturer focusing on sustainable practices with 100% recycled wood content and biomass energy usage. Sonae Arauco produces advanced high-performance fiberboards with broad distribution across Europe and the Americas.

West Fraser, Arauco, Roseburg, and Weyerhaeuser dominate the US market with consistent quality control and comprehensive distribution networks. These brands offer reliable supply chains and meet stringent regulatory standards.

Specialty Chemical and Adhesive Suppliers

IMARC Group notes that Dynea AS provides premium adhesive solutions for HDF production. These specialized chemicals contribute significantly to the final product’s performance characteristics and environmental compliance.

Advantages and Benefits of High Density Fiberboard

Superior Strength and Durability

The high-pressure manufacturing process creates a dense material structure that resists impact and wear better than standard alternatives. This makes HDF ideal for commercial applications where durability is non-negotiable. Unlike laminated wood products, HDF maintains consistent properties throughout its thickness.

Surface and Finish Quality

HDF’s smooth surface layer accepts paint, veneer, and other finishes exceptionally well. The consistent surface texture eliminates the grain patterns found in natural wood, providing a uniform base for high-quality finishes. Edge quality remains sharp and clean, reducing finishing time.

Environmental and Sustainability Benefits

Modern HDF production utilizes recycled wood fibers and green energy sources, supporting circular economy principles. Major manufacturers have adopted biomass energy and waste reduction practices, making HDF an environmentally responsible choice compared to virgin wood products.

Current Trends and Innovations in HDF Manufacturing (2026)

Sustainable Manufacturing Practices

The industry has shifted rapidly toward recycled materials adoption and biomass energy utilization. Leading manufacturers now implement circular economy principles, reducing waste and environmental impact while maintaining product quality standards.

Market Growth Areas

DIY and craft segments show significant expansion as HDF becomes more accessible to hobbyists and custom woodworkers. The material’s workability and consistent surface make it attractive for decorative applications and small-scale projects. This differs from specialized products like sande plywood or luan plywood that serve specific construction needs.

Certification and Standards Evolution

Low-emission adhesive technologies continue advancing, with stricter formaldehyde regulations driving innovation. Sustainable forestry practice requirements and enhanced certification standards reflect growing environmental awareness in the industry.

Technical Specifications and Key Facts

Density and Physical Properties

Standard HDF density exceeds 50 lbs/ft³, significantly higher than MDF’s 30-50 lbs/ft³ range. Thickness options range from 1/8″ to 3/4″ or more, with custom sizes available from major manufacturers. This density provides superior structural integrity for demanding applications.

Performance Specifications

HDF offers moderate moisture resistance when properly sealed, though it’s not fully waterproof. Load-bearing capacities exceed standard MDF, making it suitable for structural applications. Surface smoothness standards meet or exceed requirements for high-quality finishing work.

Industry Standards and Certifications

TSCA Title VI compliance addresses formaldehyde emissions, while FSC certification covers sustainable sourcing requirements. NAF (No Added Formaldehyde) standards represent the highest environmental performance level available in the market today.

FAQs

What Is High Density Fiberboard Used For?

High density fiberboard, or HDF, is used in a variety of applications including furniture manufacturing, cabinetry, and flooring. It is valued for its durability and smooth surface which makes it ideal for painting and finishing.

How Is High Density Fiberboard Different From MDF?

HDF is denser and stronger than medium density fiberboard (MDF). It is more resistant to impact and wear, making it suitable for higher traffic areas. HDF has a harder surface and a finer texture than MDF, which contributes to its durability.

Is High Density Fiberboard Waterproof?

While HDF is more water-resistant than other fiberboards, it is not completely waterproof. To increase its moisture resistance, it can be treated with sealants or used with water-resistant coatings.

Can High Density Fiberboard Be Painted Or Stained?

Yes, HDF can be both painted and stained. Its smooth surface allows for excellent paint adhesion and provides a uniform finish. Sanding it lightly before applying paint or stain is recommended for best results.

What Are The Disadvantages Of Using High Density Fiberboard?

The main disadvantages of using HDF include its susceptibility to water damage if not properly sealed, its weight compared to other materials, and the potential emission of volatile organic compounds (VOCs) due to the resins used in its production.