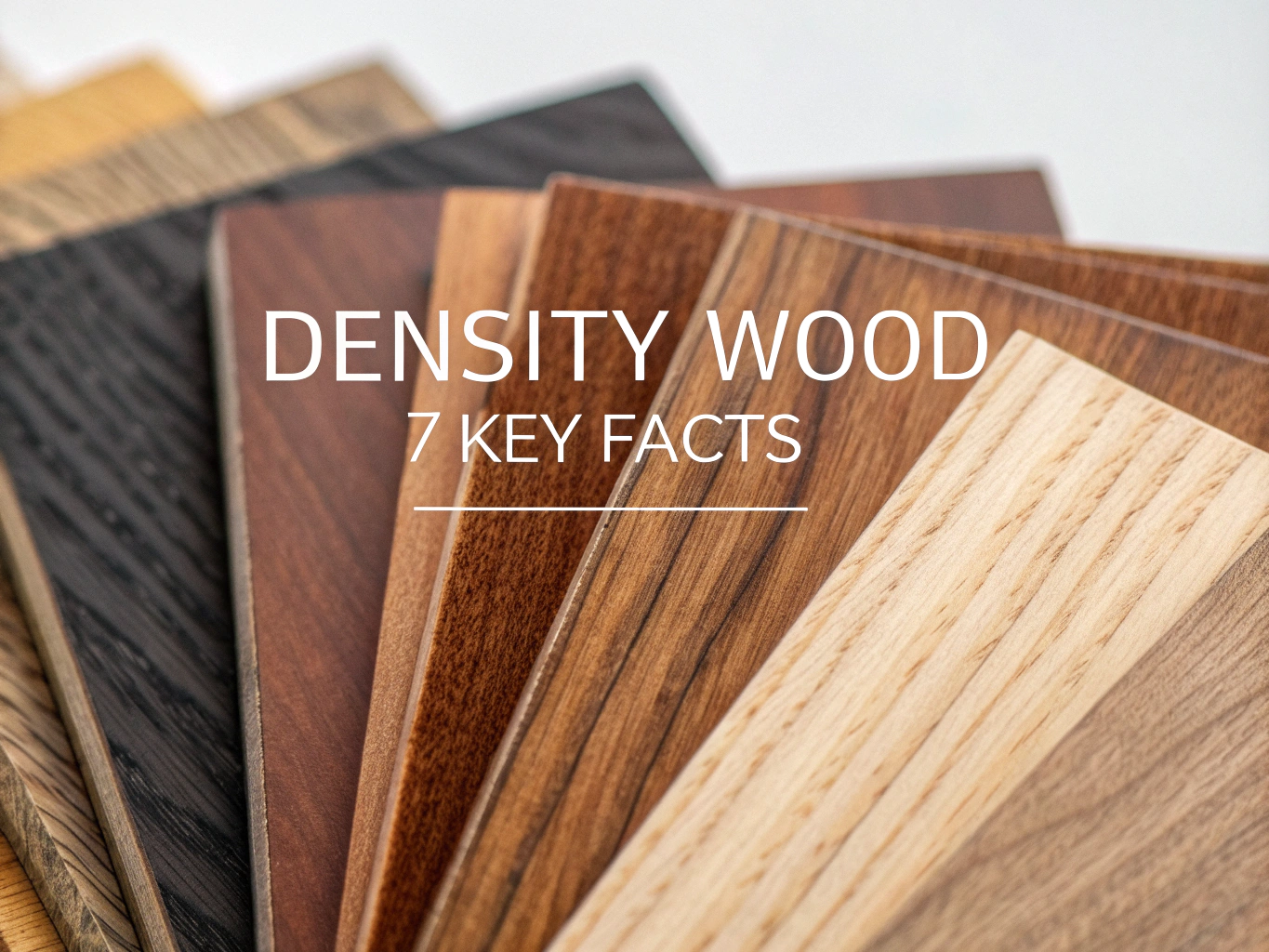

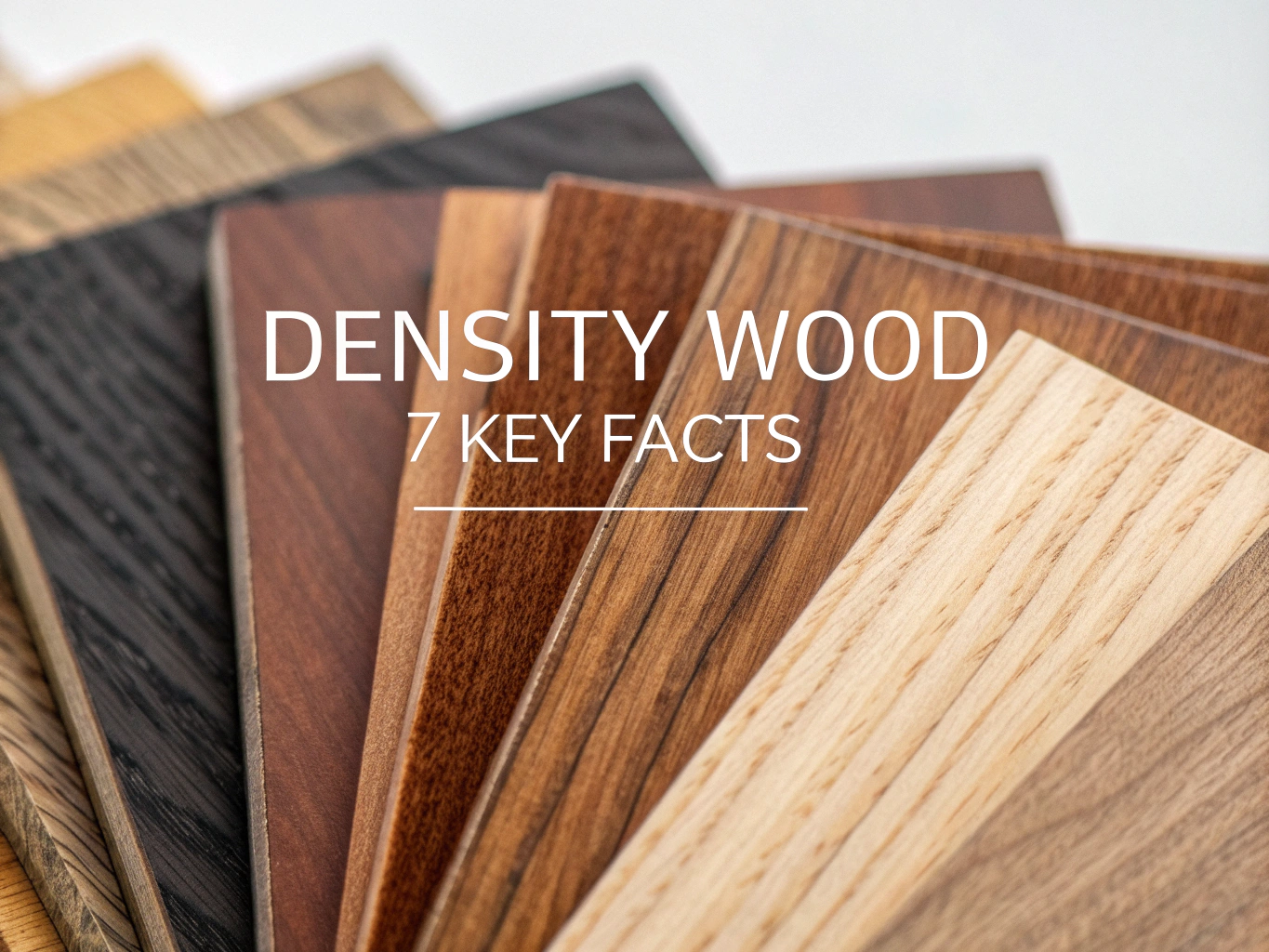

Density of Wood: 7 Key Facts Every Maker Should Know

Did you know some woods weigh less than 200 kg/m³ while others top 1,200 kg/m³? Density shapes a wood’s strength, feel, and weight. In this post I explain how experts measure wood density, why moisture changes readings, and where common hardwoods and softwoods sit on the scale. Read on for seven clear facts to help you pick the right wood for any project.

Table of Contents

The density of wood drives strength, weight, burn time, and machining quality, so builders and makers watch it closely with every project. This guide explains what the density of wood means, how to measure it, typical wood densities by species, and why those numbers matter in real work.

Understanding the Density of Wood

What is Wood Density?

Wood density is the mass per volume of a piece of wood, usually expressed in kg/m³ or g/cm³, and it answers the common question, “what is the density of wood?”. Higher values usually mean greater hardness, better wear resistance, and longer burn times, while lower values give lighter weight and easier workability.

Many references compare species at a standardized moisture level, so you can predict strength, weight, and performance before you buy. For a clear overview of properties that link to density, see Britannica — Properties of wood for background on structure and mechanical behavior.

Higher density wood tends to be stronger and more wear resistant, while lower density wood is lighter and easier to machine.

Practical rule used by woodworkers and engineers

How Wood Density is Measured

Most comparisons use air-dry samples near 12% MC (moisture content), or oven-dry tests with a correction to a common reference. The mass density of wood depends on both species and moisture; wetter boards weigh more per given volume.

Common Units and Standards

Common units include kg/m³, g/cm³, and lb/ft³, with conversions used for international work. Many labs publish density at 12% MC to keep numbers comparable across species.

How Wood Density is Measured

Measurement Methods

You can measure the density of wood at home with a small block, a precise scale, and calipers for dimensions; this gives practical, repeatable results. Pros often test oven-dry density, then adjust to 12% MC for direct comparison with published data.

- Cut a defect-free sample with straight grain.

- Measure length, width, and thickness with calipers.

- Compute volume (L × W × T), converting to cm³ or m³.

- Weigh the sample on a scale with gram precision.

- Divide mass by volume to get density; note moisture content.

- Repeat 2–3 times and average for reliable numbers.

Moisture Content Impact

Water adds weight but barely changes the piece’s outer dimensions, so density rises with moisture. Methods and correction factors used by foresters are outlined in USDA Forest Service Research Note, which helps you compare air-dry and oven-dry values.

Specific Gravity vs. Density

Specific gravity compares wood to water by ratio, while density gives actual mass per unit volume. Many charts list both; you can convert quickly since 1.0 g/cm³ equals 1,000 kg/m³.

Typical Wood Density Ranges

Global Density Variations

Across species, wood densities span ~200–1,200 kg/m³, with temperate woods clustering between 300 and 900 kg/m³. See the World Agroforestry wood density database for measured values used in carbon and forest studies.

Softwood vs. Hardwood Ranges

Average softwoods run ~350–600 kg/m³ and suit framing, craft panels, and easy machining. Average hardwood density rises to ~600–1,200 kg/m³, giving better wear resistance for floors, benches, and heavy-duty uses.

Extreme Examples

Balsa sits near ~160 kg/m³ and feels featherlight, perfect for models and balsa wood craft projects with very low weight. At the other end, lignum vitae can exceed 1,200 kg/m³ and even sink in water.

Below are a few popular blanks and sheets that reflect this range in density and use cases.

6-Pack 12x12 Basswood Craft Sheets

- Thin 1/16 inch sheets easy to cut and shape

- Smooth, unfinished surface ready for paint, stain, or wood burning

- Ideal for laser cutting and detailed model work

- Lightweight yet stable for layering and framing projects

- Versatile for crafts, drawing, engraving, and school projects

Maple Wood Sheets 4x8 1/8 inch

- Fine-grain Canadian maple ideal for veneer and signs

- Smooth surface ready for staining, engraving, or painting

- Uniform 1/8 inch thickness for consistent application

- Easy to cut, sand, and glue for craft projects

- Durable hardwood finish for long-lasting pieces

Poplar Board 1/4 x 3.5 x 24 in

- Solid American poplar with a smooth planed surface

- Thin board ideal for board-and-batten, trim, and accents

- Takes stain and paint evenly for attractive finishes

- Lightweight and stable for crafting and small shelving

- Easy to cut, rout, and fasten for quick projects

Ironwood Turning Blank 6x3x2 in

- Dense exotic hardwood built for durability and wear resistance

- Excellent for turning, carving, and knife handles

- Rich natural grain creates striking finished pieces

- Stable, heavy blank ideal for fine woodworking

- Ready for sanding, polishing, and custom finishing

Wood Densities by Species

Common Hardwood Densities

These figures reflect typical air-dry density near 12% MC and help match hardwood density to floors, furniture, and joinery. Values vary by region, age, and growth rate; use them as a practical planning range.

| Hardwood | Approx. Density (kg/m³ at ~12% MC) |

|---|---|

| Oak (red/white) | 680–750 |

| Maple (hard) | 630–755 |

| Walnut | 610–660 |

| Ash | 650–700 |

| Beech | 700–730 |

| Ironwood | 1,000–1,200+ |

For a broad cross-species chart you can compare with your samples, see the Nova Density Chart and align your target specs by unit.

Popular Softwood Densities

Pine runs ~350–560 kg/m³, spruce ~400–500, and fir ~430–550 at ~12% MC, which keeps weight down for framing and craft panels. These wood densities favor easy nailing, quick machining, and lower shipping cost.

Exotic and Specialty Woods

Ebony often sits ~950–1,100 kg/m³ and takes a glassy polish for inlays; see ebony wood for traits and uses. Bubinga averages ~800–950 kg/m³ with striking figure, covered here: bubinga wood for tonewood and furniture.

If you need a smooth, uniform maple panel for engraving tests or density comparisons, consider these thin sheets for small projects

Maple Wood Sheets 4x8 1/8 inch

- Fine-grain Canadian maple ideal for veneer and signs

- Smooth surface ready for staining, engraving, or painting

- Uniform 1/8 inch thickness for consistent application

- Easy to cut, sand, and glue for craft projects

- Durable hardwood finish for long-lasting pieces

Hardwood vs. Softwood Density

Density Comparison Overview

Hardwood density generally exceeds softwood values, which boosts wear resistance, fastener holding, and stability. A quick reference to heavy species and their traits appears in the Wood Database — Strongest woods, useful for selecting demanding applications.

Density of Maple Wood

Hard maple averages about 630–755 kg/m³, which places it in the higher end of common flooring woods. That density supports crisp machining, good wear life, and strong screw holding for benches and tops.

Performance Characteristics

Heavier species resist dents and abrasion, while lighter species cut faster and reduce tool strain. Match density to your need: durability for floors and handles, or light weight for casework, trim, and models.

Factors Affecting Wood Densities

Moisture Content Effects

As MC rises, the mass density of wood increases since bound and free water add weight without much change in outer dimensions. Publish or compare numbers at the same MC (commonly 12%) to keep your data clean.

Growth Conditions

Slow growth, tighter rings, and harsher climates can push density up, while rapid growth usually lowers average density. Soil nutrients, altitude, and site exposure also shift grain and mass per unit volume.

Tree Location and Defects

Trunk wood tends to be denser than branches, and juvenile wood near the pith is lighter than mature heartwood. Knots, reaction wood, and irregular grain change local density and reduce clear-wood strength.

Engineered Wood Density

Density of MDF Wood

The density of MDF wood typically falls between 600 and 800 kg/m³, higher than many softwoods and lower than heavy hardwoods. For classroom projects and smooth paint finishes, MDF’s uniformity makes cutting and routing very predictable

24-Pack 12x12 MDF Craft Boards

- Consistent 1/8 inch thickness for reliable results

- Smooth surface ideal for painting and stenciling

- Easy to cut, sand, and engrave for DIY projects

- Economical bulk pack for classrooms and craft rooms

- Great for signs, mixed media, and model bases

Plywood Variations

Plywood density depends on the veneer species and glue content, often similar to the softwood or hardwood core used in the panel. For quick estimates by sheet size and thickness, this guide to plywood weight helps plan handling and loads.

Composite Materials

OSB and particleboard center near 600–750 kg/m³, while high-density fiberboard is tighter and heavier than MDF in the same thickness. Learn more about high-density fiberboard for cabinet doors and smooth laminates.

Applications and Importance of Wood Density

Construction Applications

High-density woods suit flooring, worktops, tool handles, and structural parts that face compression and wear. Lower-density species reduce weight for trim, casework, and panels that benefit from quick cutting and easy fastening.

Fuel and Energy Uses

Dense hardwoods burn longer and produce more heat per log, which improves stove efficiency. Lighter species catch quickly and help start fires but require more frequent refueling.

Educational Tools

Teachers can compare the mass density of wood with plastics and metals using compact cylinder kits for classroom labs

12-Piece Density Cylinder Set with Storage Block

- Includes a variety of materials to compare densities in one kit

- Cylinders illustrate differences in mass and volume for experiments

- Comes with a handy storage block to keep pieces organized

- Great for classroom demonstrations and hands-on learning

- Compact set perfect for labs and STEM activities

FAQs

What Is The Density Of Different Types Of Wood?

Wood density varies widely: very light woods like balsa are around 100-200 kg/m³, softwoods (pine, spruce) typically range 350-550 kg/m³, and many hardwoods (oak, maple) fall between 600-900 kg/m³. Actual values depend on species, growth conditions, and moisture content.

How Is Wood Density Measured?

Density is mass divided by volume and is usually reported in kg/m³ or g/cm³. Common methods use an accurate scale and either calipers to calculate volume or water displacement for irregular samples; standardized tests often measure oven-dry mass on a specified moisture basis according to ISO or ASTM procedures.

Why Does Wood Density Matter In Construction?

Density influences strength, stiffness, durability, and weight. Higher-density woods generally carry heavier loads and resist wear better, while lower-density woods are lighter and offer better thermal insulation. Density also affects fastener holding, machining, and finishing, so it guides material selection for specific structural and finish requirements.

Does Wood Density Affect Its Strength?

Yes. There is a strong correlation between density and mechanical properties: denser woods tend to be stronger and stiffer in bending, compression, and tension. However, species characteristics, grain orientation, and defects also matter, so density is a useful predictor but not the sole determinant of strength.

How Does Moisture Content Affect The Density Of Wood?

Moisture adds mass and can change volume, so increasing moisture content raises measured density on a mass/volume basis. Drying reduces mass and shrinks volume, so reported density depends on the reference moisture basis; that is why densities are often given on an oven-dry or 12% moisture basis for consistency.