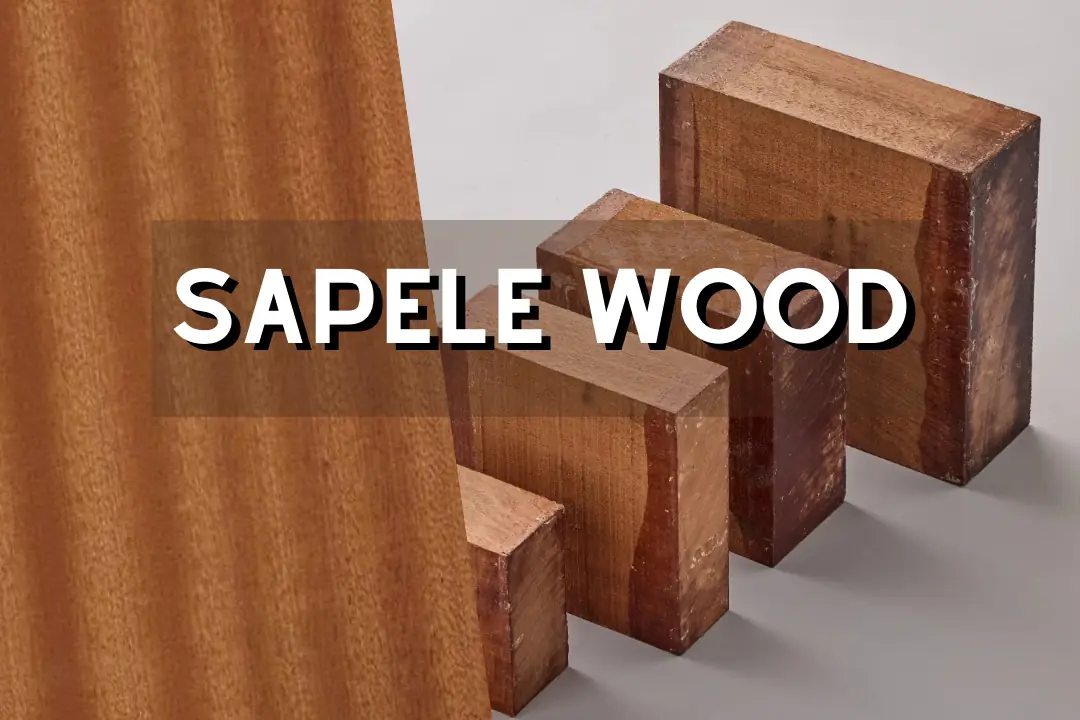

Have you ever wondered what makes Sapele wood stand out among other hardwoods? Known for its stunning beauty and impressive strength, Sapele wood offers a unique combination of quality and affordability. Whether you’re crafting furniture or building an instrument, this wonderful material may be the solution you’ve been searching for.

Table of Contents

Sapele wood (Entandrophragma cylindricum) stands out as a premium African hardwood that delivers exceptional strength, weather resistance, and mahogany-like beauty at a more accessible price point. With its distinctive ribbon grain patterns and impressive Janka hardness rating of 6,280-6,700 N, this versatile lumber has become a top choice for both interior furniture and exterior applications.

What Is Sapele Wood?

Definition and Origin

Sapele lumber comes from the Entandrophragma cylindricum tree, native to tropical Africa. This hardwood species produces heartwood ranging from golden to dark reddish-brown that deepens beautifully with age. The wood’s interlocked grain structure creates stunning visual effects including ribbon, pommele, quilted, and wavy patterns that make each piece unique.

Many woodworkers choose sapele as a mahogany alternative because it offers similar aesthetics and performance characteristics. The species has gained popularity in furniture making, boatbuilding, and architectural applications where both beauty and durability matter.

Key Characteristics

The technical specifications of sapele wood make it stand out among hardwood options. Density ranges from 640-670 kg/m³, providing excellent structural integrity for demanding applications. The Janka hardness rating of 6,280-6,700 N exceeds that of genuine mahogany and many oak species.

Dimensional stability represents another key advantage. Radial shrinkage measures approximately 4.8%, while tangential shrinkage reaches 7.2%. The T/R ratio of 1.5 indicates predictable movement patterns that reduce warping and checking issues common with less stable woods.

Reason 1: Superior Strength and Hardness

Exceptional Durability Metrics

Sapele’s hardness rating surpasses many popular hardwood species, making it ideal for high-traffic applications. The modulus of rupture reaches approximately 110 MPa, indicating excellent resistance to bending forces. This strength translates directly into superior dent and wear resistance for flooring, worktops, and furniture components.

The wood’s crushing strength of 60.4 MPa supports heavy loads without failure. These mechanical properties make sapele suitable for structural applications where reliability matters most. Furniture makers appreciate how the wood maintains its integrity under stress while resisting the daily wear that destroys softer species.

Structural Performance

High-traffic environments benefit from sapele’s exceptional hardness characteristics. Commercial flooring installations often specify this species because it withstands heavy foot traffic without showing premature wear patterns. Kitchen worktops made from sapele resist knife marks and impact damage that would mar softer woods.

Furniture construction projects gain long-term value from sapele’s structural performance. Chair frames, table legs, and cabinet components maintain their shape and strength through decades of use. The wood’s density provides the mass needed for stable, wobble-free furniture pieces.

Reason 2: Outstanding Weather Resistance and Stability

Natural Durability

Moisture resistance makes sapele suitable for exterior applications where other hardwoods would fail. The wood’s natural extractives provide protection against rot and decay organisms. Insect resistance adds another layer of protection, reducing the risk of damage from boring insects and termites.

Exterior doors and window frames benefit from sapele’s weather tolerance. With proper water and UV-resistant finishes, the wood performs reliably in harsh climates. UK weather conditions pose no significant challenge when appropriate maintenance schedules are followed.

Dimensional Stability

Seasonal movement patterns remain predictable and minimal with sapele lumber. The wood’s balanced shrinkage characteristics prevent the warping and checking problems that plague less stable species. Exterior applications maintain their fit and finish through temperature and humidity cycles.

Door and window manufacturers choose sapele for its reliable performance. The wood maintains proper clearances and sealing surfaces without binding or gaps developing over time. This stability reduces maintenance requirements and extends service life significantly.

Reason 3: Premium Mahogany Aesthetic at Better Value

Visual Appeal

The rich reddish-brown coloration of sapele creates an immediate visual impact that rivals genuine mahogany. Age and exposure to light deepen the color to a warm, luxurious patina that improves with time. This natural aging process adds character and value to finished projects.

Ribbon grain patterns create eye-catching figure effects that make sapele ideal for statement pieces. Pommele and quilted figures add three-dimensional depth to flat surfaces. These natural patterns can’t be replicated artificially, making each board unique and valuable.

Design Versatility

Premium cabinetry projects showcase sapele’s luxury appearance at a fraction of genuine mahogany’s cost. The wood’s figure patterns work equally well in traditional and contemporary designs. Statement furniture pieces gain instant visual appeal from the wood’s natural beauty.

Decorative veneer applications maximize the impact of figured sapele while controlling costs. Musical instrument makers value the wood’s acoustic properties combined with its stunning appearance. The species offers professional-grade aesthetics without the premium pricing of rare woods.

Reason 4: Excellent Workability and Finishing Properties

Machining and Assembly

Turning characteristics make sapele popular for lathe work and curved components. The wood holds detail well and creates smooth surfaces with proper technique. Gluing properties remain reliable when surfaces are properly prepared and appropriate adhesives are used.

Polishing to high gloss finishes represents one of sapele’s standout features. The wood accepts oils, varnishes, and lacquers with excellent results. Pore filling creates mirror-like surfaces perfect for fine furniture and musical instruments.

Versatile Applications

Furniture and flooring projects benefit from sapele’s workability and appearance. The wood machines cleanly with sharp tools and accepts a wide range of finishes. Boatbuilding applications take advantage of the species’ moisture resistance and structural strength.

Musical instrument construction utilizes sapele’s acoustic properties and stability. Guitar backs, sides, and necks made from this wood produce excellent tone while resisting the movement that affects tuning stability. Decorative veneer work showcases the wood’s figure patterns in architectural applications.

Working Considerations

The interlocked grain structure requires sharp tooling to prevent tear-out during machining operations. Carbide cutters maintain their edge longer when working with this dense hardwood. Light passes and proper feed rates reduce the risk of surface defects.

Tool dulling effects mean more frequent sharpening schedules are needed. Dust extraction becomes important due to the fine particles produced during sanding and machining. Pre-drilling prevents splitting when installing fasteners in finished projects.

Reason 5: Long-Term Value and Investment

Longevity Benefits

Scratch and dent resistance extends the useful life of sapele projects far beyond softer wood alternatives. Kitchen applications maintain their appearance through years of daily use. The wood’s hardness prevents the surface damage that requires refinishing or replacement.

Exterior applications can provide decades of performance with proper maintenance schedules. Interior projects often last for generations without structural issues. This longevity makes the initial investment in quality sapele lumber pay dividends over time.

Cost Effectiveness

Lower pricing compared to genuine mahogany makes sapele accessible for projects where budget constraints matter. The wood delivers similar performance and appearance characteristics at a significant savings. This value proposition has made sapele increasingly popular among professional woodworkers.

Reduced replacement frequency provides long-term cost benefits that offset higher initial material costs. Projects built with sapele require less maintenance and last longer than those made with softer species. Professional-grade performance justifies the investment in quality lumber.

Technical Specifications and Properties

Physical Properties

Understanding sapele’s technical specifications helps in project planning and material selection. The density of 640-670 kg/m³ places it in the medium to heavy hardwood category. This density contributes directly to the wood’s strength and durability characteristics.

- Janka Hardness: 6,280-6,700 N (approximately 1,410 lbf)

- Modulus of Rupture: 109.9 MPa

- Elastic Modulus: 12.04 GPa

- Crushing Strength: 60.4 MPa

Shrinkage Data

Movement characteristics determine how sapele will behave during seasonal humidity changes. The shrinkage values support the wood’s reputation for dimensional stability. These predictable movement patterns make sapele suitable for precision applications.

- Radial Shrinkage: 4.8%

- Tangential Shrinkage: 7.2%

- T/R Ratio: 1.5 (indicates good stability)

- Volumetric Shrinkage: 12.8%

Best Sapele Wood Products for Your Projects

Small Boards and Craft Projects

These premium sapele lumber pieces work perfectly for small woodworking projects, turning blanks, and custom knife handles.

Sapele Lumber Board Set, Pack of 2

- Premium quality Sapele wood

- Great for small woodworking projects

- Measures 3/4\

Veneers and Decorative Applications

Sapele veneer sheets provide an economical way to achieve the wood’s stunning appearance in furniture restoration and decorative projects.

12-Piece Sapele Wood Veneer Sheets

- Perfect for laser cutting projects

- Smooth, unfinished surface ready for customization

- Ideal for school projects and crafting

- Easy to paint and work with various tools

- High-quality 3mm thick Sapele wood

Natural Sapele Veneer Sheet

- Ideal for furniture restoration tasks

- Perfect dimensions for versatile use

- Enhances appearance with real wood texture

- Easy to cut and apply for projects

- Loved by both professionals and hobbyists

Specialty and Kitchen Applications

Artistic and functional pieces showcase sapele’s unique ribbon patterns and durability in kitchen environments.

Working with Sapele: Tips and Best Practices

Machining Techniques

Sharp carbide tooling provides the best results when machining sapele’s dense fibers. The interlocked grain structure can cause tear-out if tools aren’t properly maintained. Light passes prevent overloading the cutting edges and reduce surface defects.

Climb-cutting on routers (where safe) helps minimize tear-out on figured grain patterns. Regular tool sharpening schedules become necessary due to the wood’s abrasive nature. High-angle plane irons work better than standard angles for hand tool operations.

Finishing and Maintenance

Pre-drilling for screws prevents splitting in this dense hardwood. Stainless steel or coated fasteners avoid the iron staining that can discolor sapele surfaces. The wood’s natural oils can interfere with some finishes, so test compatibility on scrap pieces first.

Exterior applications require water and UV-resistant finishes for maximum longevity. Pore-filling creates the smooth surface needed for mirror finishes on fine furniture. The wood accepts oils, varnishes, and lacquers with excellent results when properly prepared.

Safety Considerations

Dust extraction and PPE become important when machining sapele due to the fine particles produced. The wood has a normal cedar-like scent when freshly cut. Avoid iron contamination during glue-up and finishing to prevent yellowing or discoloration of the wood surface.

Proper ventilation helps manage dust levels during sanding operations. The dense nature of sapele creates more airborne particles than softer woods. Regular cleaning of dust collection systems maintains their effectiveness with this abrasive material.

FAQs

What Are The Uses Of Sapele Wood?

Sapele wood is a popular choice for furniture, musical instruments, and cabinetry due to its attractive appearance and durability. It is also used for flooring, boat building, and decorative veneers.

Is Sapele Wood Good For Flooring?

Yes, sapele wood is excellent for flooring. Its resilience to wear and tear, combined with its rich color and fine grain, make it a high-quality option for both residential and commercial flooring applications.

How Does Sapele Wood Compare To Mahogany?

Sapele wood is often compared to mahogany due to their similar appearance. However, sapele tends to be slightly harder and more stable, making it a great alternative for projects requiring durability.

What Is The Cost Of Sapele Wood Per Board Foot?

The cost of sapele wood can vary, but it generally ranges from $5 to $7 per board foot. Prices may fluctuate based on quality, availability, and regional demand.

How Do You Care For Sapele Wood Furniture?

To maintain sapele wood furniture, regularly dust it and use a mild wood cleaner to prevent buildup. Avoid excessive moisture and direct sunlight to preserve its finish and prevent warping.