Black MDF: 5 Surprising Facts to Know

Think you know all about wood materials? **Black MDF** might just surprise you. Unlike regular wood, this material combines the sleek modern look of black wood with the consistency of engineered panels. Whether you’re crafting furniture or creating eye-catching displays, Black MDF offers both reliability and style. Let’s dive into what makes Black MDF a standout choice for so many projects.

Table of Contents

Black MDF represents a specialized form of medium density fiberboard that comes pre-finished with a uniform black color, eliminating the need for additional painting or staining. This engineered wood product has gained significant traction in modern design applications, offering the aesthetic appeal of black wood while maintaining the superior workability and cost-effectiveness that MDF is known for.

What is Black MDF?

Black MDF is an engineered wood product created by pressing wood fibers under heat and pressure, then applying a black finish during manufacturing. The composition typically includes 82% wood fiber, 9% urea-formaldehyde resin, 8% water, and 1% paraffin wax, according to Wikipedia’s MDF documentation. This creates a uniform black surface that maintains consistency throughout the material’s thickness.

The density of black MDF ranges from 500–1000 kg/m³, making it denser than particleboard but lighter than most hardwoods. This density provides excellent stability while remaining easy to machine and work with standard woodworking tools.

Fact 1: Black MDF Offers a Unique Combination of Consistency and Aesthetics

Black MDF features a homogeneous structure without visible wood grain, creating smooth edges and faces that are impossible to achieve with natural wood. This characteristic makes it particularly valuable for retail displays, exhibitions, and upscale interiors where a sleek black wood appearance is desired.

The absence of knots or imperfections increases workability compared to natural black wood options. This eliminates risks of splintering and voids that can occur with solid wood materials. The uniform color extends throughout the sheet thickness with certain manufacturers, enabling intricate routing or engraving with consistently black edges.

Unlike traditional wood that requires staining or painting to achieve a black finish, black MDF delivers immediate visual impact without additional surface preparation. This saves both time and labor costs in manufacturing and construction applications.

Fact 2: Black MDF is Extremely Versatile for Cutting, Shaping, and Machining

Black MDF can be cut, machined, drilled, or routed cleanly without chips or splinters. This superior machinability makes it ideal for complex projects that require precise cuts and detailed work. The material responds well to both hand tools and power tools, maintaining clean edges throughout the cutting process.

The edges can be left exposed since the color remains consistent—a rare advantage in fiberboard products. This feature makes black MDF perfect for laser cutting applications, decorative panels, signage, and furniture components where exposed edges are part of the design aesthetic.

Black MDF accepts additional surface treatments including veneers, laminates, or lacquers for custom decorative applications. This flexibility allows designers to create layered finishes while maintaining the structural benefits of the MDF core. For those interested in comparing different engineered materials, high density fiberboard offers similar workability with increased durability.

Fact 3: Increasing Demand and Market Size for MDF

The global MDF market reached USD 42.26 billion in 2023 and is projected to reach USD 70.98 billion by 2032, according to Fortune Business Insights. This represents a compound annual growth rate of 5.6% from 2024–2032, indicating strong market confidence in MDF products.

MDF is widely preferred in applications such as furniture, cabinets, shelving, wall paneling, and flooring. Black MDF specifically targets markets where black wood aesthetics are required without sacrificing price or availability. The Asia-Pacific region held 58.87% of the global MDF market share in 2023, driving much of this growth.

This market expansion reflects increasing demand for engineered wood products that offer consistent quality and predictable performance. Black MDF benefits from this trend by providing designers with a reliable alternative to naturally dark woods or painted surfaces.

Fact 4: Black MDF Can Be Engineered for Special Uses

Specialty black MDF panels can be infused or coated for added performance characteristics. These include moisture resistance and fire retardance properties that expand the material’s application range beyond standard interior uses. Standard black MDF isn’t inherently suitable for wet environments, but select variants are available for high-traffic or demanding installations.

Research demonstrates that engineered MDF panels can provide electromagnetic shielding by incorporating carbon fibers, as documented in BioResources studies. This opens potential applications in electronics and secure environments where both aesthetic appeal and functional performance are required.

Black MDF serves as an alternative to black plywood or stained black wood in situations where cost, machinability, or finish uniformity are priorities. The engineered nature allows for consistent performance across large production runs, something that’s difficult to achieve with natural wood products.

Fact 5: Black MDF is Cost-Effective Compared to Solid Black Wood

Black MDF is less expensive and more stable than most solid black wood or engineered black wood surfaces. This cost advantage becomes particularly significant in large-scale projects where material costs can impact overall project feasibility.

The material offers greater sheet size versatility, typically available in 4×8 feet sheets or custom dimensions. Thickness options range from 3/8″ to 1-1/4″, making it ideal for large-scale interiors and commercial applications. This standardization reduces waste and simplifies project planning.

Sheet waste is minimized compared to solid wood, and material costs remain predictable throughout the project lifecycle. This contrasts with the variable pricing of black-stained hardwood, which can fluctuate based on availability and quality of the underlying wood species.

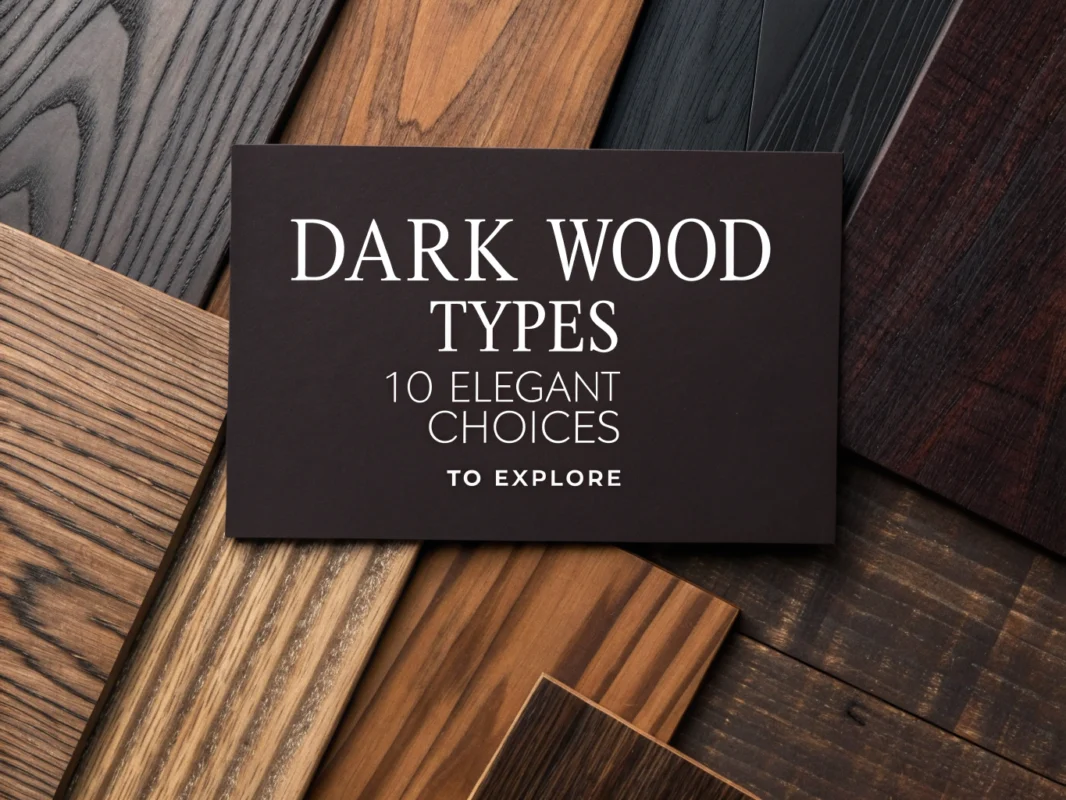

Black MDF vs. Other Black Sheet Materials

Comparing black MDF to other black sheet materials reveals distinct advantages and applications for each option:

| Property | Black MDF | Black Phenolic Plywood | Black ABS Sheet | Black Plexiglass |

|---|---|---|---|---|

| Composition | Engineered wood fiber panel | Baltic birch with black phenolic resin finish | Thermoplastic polymer (ABS) | Acrylic (PMMA) |

| Machinability | Excellent | Very good | Good | Limited (cracks if sawed) |

| Edge Color | Uniform black (some brands) | Black faces, edges may show raw wood | Black throughout | Black throughout |

| Applications | Furniture, displays, signs | Cabinets, crafts, construction | Signs, DIY, robotics | Signs, crafts, glazing |

| Moisture Resistance | Low-medium (unless treated) | High (phenolic coating) | High | High |

For projects requiring superior moisture resistance, cabinet plywood grades offer enhanced durability compared to standard MDF options.

Black Phenolic Birch Plywood, 12x24

- Durable construction for long-lasting use

- Ideal size for home and craft projects

- Smooth surface for easy painting and finishing

- Lightweight yet sturdy material

- Made from high-quality Baltic Birch.

Custom and DIY Applications for Black MDF

Home Interior Applications

Black MDF excels in modern wall paneling applications where a sophisticated black wood appearance is desired without the expense of solid wood. The material works well for furniture construction, open shelving systems, and accent walls that require a uniform finish.

The material accepts engraving and CNC-machining for custom decor or commercial branding applications. This capability allows for personalized designs that maintain the professional appearance of the black finish.

Display and Decorative Applications

Black MDF serves excellently as display bases and decorative objects where a refined appearance is needed:

Black MDF Display Base with Ogee Edge, 9x6

- Elegant ogee edge for a polished look

- Perfect size for displaying collectibles

- MDF wood provides sturdy support

- Black finish complements any decor

- Easy to clean and maintain.

Commercial and Retail Applications

Retail signage and commercial branding benefit from black MDF’s consistent appearance and ease of fabrication. The material cuts cleanly for precise lettering and maintains sharp edges that enhance the professional appearance of business displays.

For specialized applications requiring different material properties, Richlite offers an alternative engineered material with unique characteristics. Similarly, understanding plywood grades can help in selecting the right material for specific project requirements.

Material Selection Considerations

When selecting black MDF for projects, consider the following factors to ensure optimal results:

- Moisture exposure – Standard black MDF isn’t suitable for wet environments

- Load requirements – MDF has lower load-bearing capacity than solid wood

- Edge finishing – Verify that the black color extends through the material thickness

- Tool requirements – Sharp cutting tools prevent fuzzing and maintain clean edges

- Ventilation needs – Proper ventilation is important when cutting or sanding MDF

Black MDF represents a versatile solution for projects requiring the aesthetic appeal of black wood with the practical benefits of engineered materials. Its combination of workability, consistency, and cost-effectiveness makes it an excellent choice for both professional and DIY applications. For projects requiring enhanced structural properties, exploring laminated wood options might provide additional benefits while maintaining design flexibility.

FAQs

What Is Black MDF Made Of?

Black MDF is made from medium-density fiberboard that is dyed black throughout its structure. It consists of wood fibers bonded together with resin adhesive under heat and pressure, creating a uniform panel perfect for various applications.

How Does Black MDF Differ From Regular MDF?

While both black MDF and regular MDF are similar in structure, black MDF is infused with dye during the manufacturing process, ensuring a consistent color throughout. This means there’s no need for painting or finishing the surface, making it ideal for visible applications.

Can Black MDF Be Used For Outdoor Projects?

Black MDF is generally not recommended for outdoor projects. MDF is susceptible to moisture and can swell or deteriorate when exposed to outdoor elements. For outdoor use, it is better to choose materials specifically designed to withstand weather conditions.

What Are The Best Uses For Black MDF In Home Décor?

Black MDF is excellent for home décor applications such as furniture, cabinetry, shelving, and wall paneling. Its sleek and modern appearance makes it a stylish choice for those looking to enhance the interior design of their space.

How Do You Cut And Finish Black MDF Without Chipping?

To cut black MDF without chipping, use a sharp carbide-tipped blade on a table saw or circular saw. To finish the edges smoothly, sand them lightly with fine-grit sandpaper. This approach generally prevents chipping and maintains the board’s appearance.