S4S Lumber: 7 Key Facts for Smart Buyers

Ever wondered why seasoned woodworkers rave about S4S lumber? This versatile material is the go-to choice for those seeking precision and ease in their projects. Imagine skipping the tedious, time-consuming steps of milling and planing! With smooth, ready-to-use boards, S4S lumber can help you kickstart your next masterpiece in no time.

Table of Contents

S4S lumber represents a premium option for woodworkers who value time efficiency and precision in their projects. This pre-surfaced lumber comes ready to use with all four sides planed smooth, eliminating the need for additional milling work that can consume hours of project time.

What Is S4S Lumber and How It’s Made

Definition and Basic Characteristics

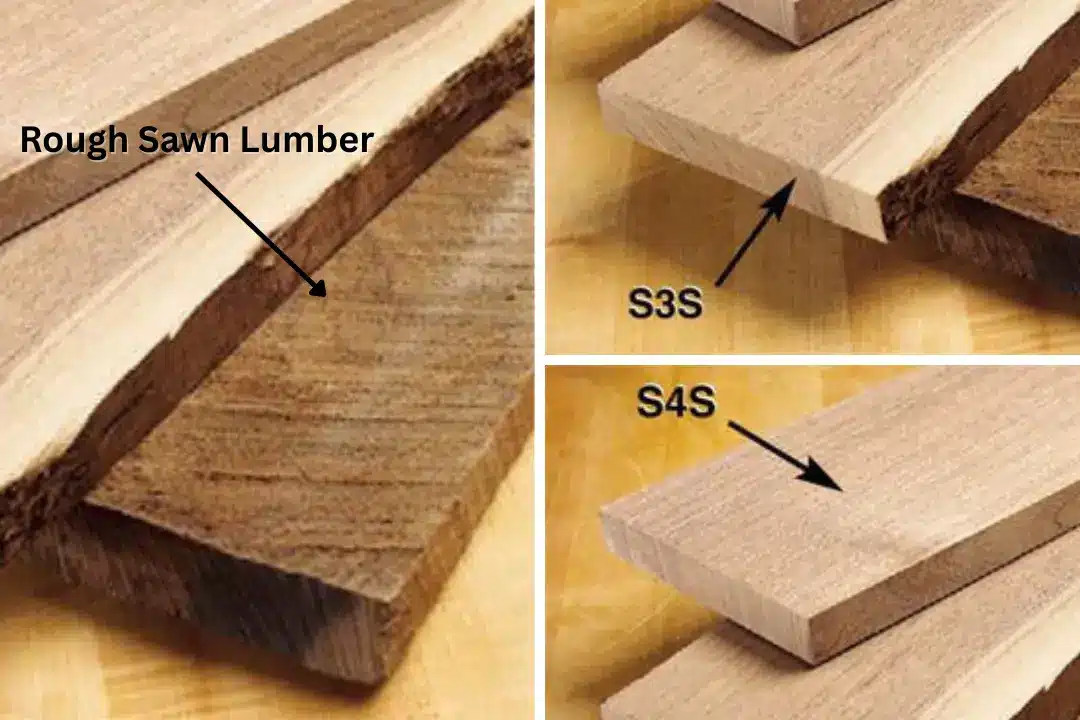

S4S lumber stands for “Surfaced on Four Sides” according to Advantage Lumber. All four sides of the board—two faces and two edges—are planed smooth and squared at the mill. This creates dimensionally accurate, flat, and smooth boards that are ready for immediate use, unlike rough sawn lumber which remains coarse and uneven.

The result is consistent shape and size across every board. Each piece arrives with four square corners and uniform dimensions that meet industry standards. This precision makes S4S lumber ideal for projects where accuracy matters most.

The Surfacing Process

Boards undergo planing after initial sawing to obtain uniform thickness and width. The surfacing process is categorized by how many sides receive treatment. KJP Select Hardwoods explains that S4S represents the most processed option compared to S2S (two sides) and S3S (three sides).

This comprehensive surfacing creates boards with four square corners and consistent dimensions throughout. The milling process removes irregularities and ensures each piece meets exact specifications for professional woodworking applications.

Key Advantages That Make S4S Worth the Investment

Time and Labor Savings

S4S lumber allows woodworkers to skip milling, jointing, or planing processes entirely. This enables faster project starts, which proves especially useful for tight schedules or small workshops without extensive machinery. The time savings can amount to hours per project by eliminating setup and preparation steps.

This lumber type serves professionals, beginners, and DIYers equally well. Anyone can focus on construction and assembly rather than spending time on material preparation. The convenience factor makes complex projects more accessible to woodworkers at all skill levels.

Ready-to-Use Convenience

S4S lumber works perfectly for furniture, cabinetry, shelving, and high-finish carpentry projects. The smooth surfaces and square edges make it ideal for visible faces where appearance matters most. Projects can move straight to assembly without additional surface preparation.

The immediate assembly capability proves invaluable for time-sensitive projects. Cabinet makers and furniture builders can begin construction right away, knowing that all pieces will fit together with precision. This reliability reduces project delays and material waste.

Dimensional Accuracy

Boards arrive with standardized, consistent thickness and width according to industry norms. This eliminates the guesswork involved with rough lumber and minimizes the need for adjustments during construction. Each piece matches the specified dimensions within tight tolerances.

This precision makes S4S lumber perfect for applications requiring tight fits and square joints. Cabinet doors, drawer boxes, and furniture components benefit from the dimensional consistency that S4S lumber provides straight from the supplier.

S4S vs Other Lumber Types: Complete Comparison

S2S Lumber

S2S lumber receives surfacing on two faces only, leaving the edges rough and unfinished. Northcastle Hardware notes that this option requires further planing or jointing to achieve smooth edges. The cost savings come at the expense of additional work time.

This lumber type works well when edge appearance doesn’t matter or when custom edge profiles are planned. The rough edges provide flexibility for creating unique shapes or fitting irregular spaces.

S3S Lumber

S3S lumber features surfacing on two faces and one edge, leaving one rough edge for flexible width adjustments. This option provides more finishing than S2S while maintaining some customization capability. The single rough edge allows for trimming to exact widths as needed.

Woodworkers choose S3S when they need partial customization flexibility without starting from completely rough material. This middle-ground option balances convenience with adaptability for specific project requirements.

Rough Sawn Lumber

Rough sawn lumber receives no surfacing treatment, making it the most economical option available. This lumber offers maximum thickness for custom dimensions since no material is removed during planing. The trade-off involves significantly more preparation work before use.

This option suits projects where cost takes priority over convenience. Woodworkers with full shop setups can process rough lumber to their exact specifications, potentially saving money on larger projects while maintaining complete control over final dimensions.

Best Applications for S4S Lumber Projects

Furniture and Cabinetry

S4S lumber excels in furniture construction projects like tables, chairs, and cabinet frames. The smooth surfaces and precise dimensions create professional results without extensive preparation time. Cabinet makers particularly value the consistency for door and drawer construction.

Projects where surface smoothness is crucial benefit most from S4S lumber. Fine furniture pieces, jewelry boxes, and display cases require the level of finish that S4S lumber provides right from the start. This eliminates surface preparation steps that could introduce inconsistencies.

Visible Elements

Shelving and bookcases with exposed faces and edges showcase S4S lumber’s advantages perfectly. All visible surfaces arrive ready for finishing without additional planing or sanding. This saves considerable time on projects where appearance matters most.

- Doors and trim work requiring precise fits

- Moldings with consistent profiles

- Cutting boards needing smooth surfaces

- Decorative items where finish quality matters

DIY Woodworking

DIY projects that prioritize clean finish and ease-of-use work perfectly with S4S lumber. Home woodworkers without extensive shop equipment can achieve professional results using S4S lumber as their starting material. The convenience factor makes complex projects more approachable for hobbyists.

Weekend projects benefit from reduced setup time and immediate usability. Garage workshops and basement shops can tackle ambitious projects without investing in expensive planing equipment or spending hours on material preparation.

Popular S4S Lumber Species and Sizing Options

Common Hardwood Species

Popular S4S hardwood options include Maple, Cherry, Walnut, Oak, and Poplar. Each species offers different characteristics for specific applications. Cherry wood provides excellent finishing properties, while red oak offers strength and durability for structural applications.

Various grades are available including Select and #1 Common classifications. Select grade offers the highest appearance quality with minimal defects, while #1 Common provides good value with some character marks that many woodworkers find appealing.

Standard Dimensions

S4S dimensions are expressed as nominal size before surfacing. Actual measurements typically run 1/4″ to 1/2″ less after the planing process removes material from all four sides. This sizing convention follows industry standards across all lumber suppliers.

Standard lengths and thicknesses are widely available from most suppliers. Common thicknesses include 3/4″, 1″, 1-1/4″, and 1-1/2″ actual dimensions. Lengths typically range from 4 feet to 16 feet depending on species and supplier inventory.

Recommended S4S Lumber Products

These curated lumber packs offer excellent value for woodworkers starting projects with premium S4S materials:

Woodworking Variety Pack: Walnut, Maple & Cherry

- Includes 5 walnut, 5 maple, and 5 cherry boards

- Perfect for mixed wood projects

- Uniform 3/4 x 2 x 12 inch size

- Craft ready and easy to work with

- Ideal for small scale woodworking.

Woodchucks Wood Combo Pack: Walnut, Cherry & Maple

- 15 boards with a rich mix of walnut, cherry, and maple

- Consistent 3/4 x 2 x 24 inch dimensions

- High-quality finish for smooth crafting

- Versatile for various woodworking needs

- Enhances project aesthetics with natural wood grains.

Barrington Hardwoods Maple Board Set

- Set of four 3/4 x 2 x 12 inch maple boards

- Durable and long-lasting hardwood

- Perfect for furniture and cabinetry

- Easy to cut and shape

- Provides a sleek, clean finish.

Walnut, Cherry & Maple Combo Pack

- 15 board pack for diverse projects

- Includes walnut, cherry, and maple

- 3/4 x 2 x 24 inch dimensions

- Smooth, planed surfaces

- Enhances array of woodworking aesthetics.

Where to Buy S4S Lumber and What to Expect

Purchase Locations

S4S lumber is available at lumberyards and woodworking specialty stores that cater to serious woodworkers. These locations typically offer the widest species selection and highest quality grades. Staff expertise at specialty stores helps match lumber to specific project requirements.

Home improvement chains and online suppliers provide convenient access to S4S lumber for smaller projects. Many retailers offer pre-packaged bundles and variety packs that work well for hobbyist woodworkers. Online ordering expands access to species that local stores might not stock.

Pricing Considerations

Hardwoods typically cost more than softwoods or pine lumber across all surfacing options. S4S lumber commands premium pricing compared to rough sawn material since the milling and finishing processes add value and convenience. This cost difference reflects the time and labor savings provided.

Prices vary significantly by species, thickness, and length. Exotic hardwoods like teak wood command higher prices than domestic species. Thicker boards and longer lengths also increase costs since they require larger source logs and more processing time.

Smart Buying Tips for Quality S4S Lumber

Quality Inspection Points

Check for surface consistency and square corners when evaluating S4S lumber quality. High-quality boards should be free from warping, cupping, or major defects that could affect project outcomes. Run your hand across surfaces to detect any irregularities in the planing.

Verify actual versus nominal measurements using a reliable measuring tool. Actual dimensions typically measure 1/4″ to 1/2″ less than nominal sizes after surfacing. This verification prevents surprises during project planning and ensures pieces fit together as expected.

Purchase Strategy

Buy extra material to account for mistakes or project adjustments that inevitably occur during construction. A 10-15% overage provides insurance against cutting errors or design changes. This small investment prevents project delays when additional material is needed.

- Compare grades for best balance of price and appearance

- Consider FSC-certified or sustainably sourced options

- Ask about volume discounts for larger projects

- Inspect boards individually when possible

When Not to Choose S4S

Projects requiring maximum thickness for custom dimensions work better with rough sawn lumber. The surfacing process removes material that might be needed for thick components or custom profiles. Large timber framing projects often require the full thickness that only rough lumber provides.

Budget-conscious projects where cost is the primary concern might benefit from rough sawn alternatives. The convenience of S4S lumber comes at a premium that may not justify the expense for utility projects or practice pieces where appearance matters less than function.

FAQs

What Does S4S Mean In Lumber?

S4S stands for “Surfaced on Four Sides.” This means that the lumber has been planed on all four sides, making it smooth, dimensionally accurate, and ready to use for various projects.

How Does S4S Lumber Compare To Rough Cut Lumber?

S4S lumber is smoother and more precise in its dimensions compared to rough cut lumber, which is typically thicker, rougher, and requires additional processing before use.

Where Can I Buy S4S Lumber Near Me?

You can purchase S4S lumber at most home improvement stores, local lumberyards, or specialized woodworking supply shops. Checking online for locations and availability can also help.

Is S4S Lumber More Expensive Than S2S Lumber?

Generally, S4S lumber is more expensive than S2S (Surfaced on Two Sides) because of the additional processing to surface all four sides.

What Are The Benefits Of Using S4S Lumber For Woodworking Projects?

S4S lumber is ready-to-use, saves time in preparation, is easy to handle, and provides a smooth finish, making it a great choice for precise and time-efficient woodworking projects.