Discover the Top 5 Uses of Phenolic Plywood

Ever wondered why phenolic plywood is becoming so popular lately? Known for its waterproof and durable nature, this material has a lot to offer in different applications. Whether you’re considering it for floors, furniture, or home projects, phenolic plywood provides strength and stability. Let’s explore its five best uses and see why it’s a top choice today.

Table of Contents

Phenolic plywood stands out as an engineered wood product that combines traditional plywood construction with a phenol-formaldehyde resin coating, creating panels with exceptional waterproof properties and mechanical strength. This specialized material has gained significant traction in 2026 across industries ranging from construction to furniture making, thanks to its ability to withstand harsh conditions while maintaining dimensional stability.

Heavy-Duty Flooring & Industrial Platforms

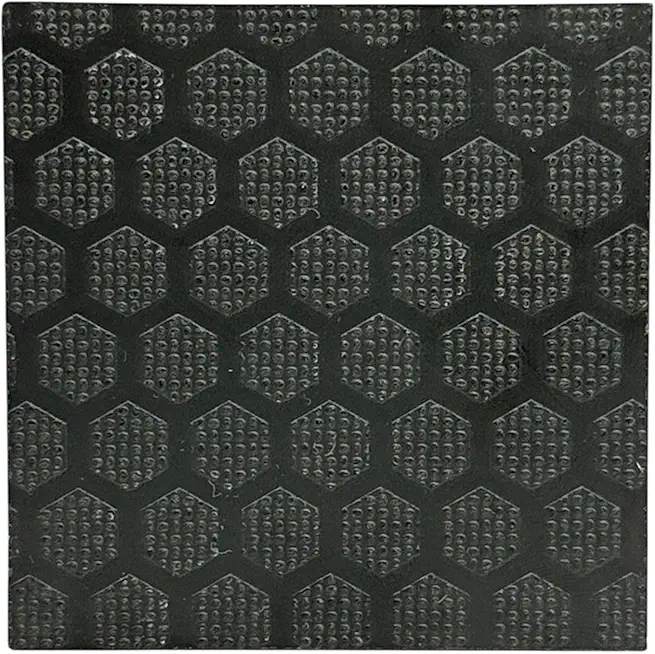

Industrial environments demand flooring solutions that can handle repeated heavy loads and exposure to chemicals. Phenolic plywood excels in warehouse floors, truck beds, and scaffolding applications where standard materials would quickly deteriorate. The anti-slip surface variants provide added safety for workers navigating these demanding spaces.

Load resistance capabilities make this material perfect for work platforms that support heavy machinery and equipment. Chemical resistance properties protect against spills and cleaning agents commonly found in industrial settings. The textured surface options reduce slip hazards while maintaining the structural integrity needed for high-traffic areas.

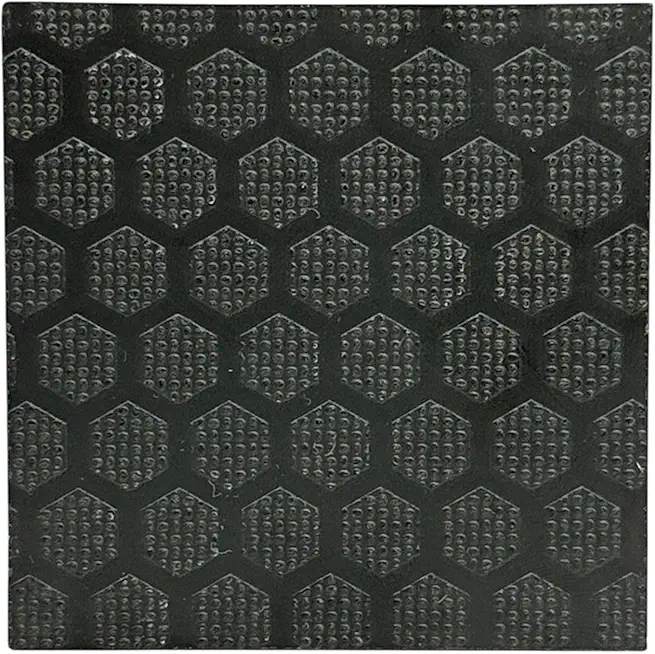

Anti-Slip Black Hex-Ply Plywood 12mm

- Anti-slip surface for safety

- High strength and stability

- Easy to handle and install

- Perfect for flooring and steps

- UV-resistant finish for longevity.

Concrete Formwork & Shuttering

Construction professionals have discovered that phenolic plywood offers superior release properties for concrete casting applications. The smooth phenolic film prevents concrete from adhering to the surface, allowing for clean removal and multiple reuses. This capability translates to significant cost savings on large construction projects.

The material’s resistance to warping and edge swelling maintains form accuracy throughout multiple concrete pours. Project managers report 50+ reuse cycles under proper handling conditions, dramatically reducing formwork replacement costs. The smooth surface finish minimizes defects on cast concrete, reducing the need for post-pour surface treatments.

Here are professional-grade options for demanding formwork applications:

Black Phenolic Plywood 18mm

- Sturdy and durable design

- Suitable for indoor and outdoor projects

- High-quality finish for professional look

- Easy to cut and work with

- Ideal for cabinetry and furniture.

Compact Black Phenolic Plywood 12mm

- Great for small projects

- Waterproof and weather-resistant

- Smooth surface for easy painting

- Durable and strong construction

- Perfect for custom carpentry.

Furniture and Cabinetry

Modern furniture designers appreciate phenolic plywood’s industrial aesthetic combined with practical durability. The material works exceptionally well in high-traffic environments like schools, offices, and laboratories where traditional wood finishes would show wear quickly. Kitchen worktops and cabinet construction benefit from the moisture resistance and easy maintenance properties.

Cutting and finishing operations proceed smoothly with standard woodworking tools. The pre-finished surface eliminates the need for additional coating in many applications. Cabinet grade materials offer consistent quality that furniture makers can rely on for professional results.

These furniture-grade options provide excellent finishing characteristics:

Light Brown Phenolic Birch Plywood 18mm

- Warm light brown tone

- Robust and versatile

- Ideal for furniture making

- Excellent surface for finishing

- Supports heavy loads with ease.

Espresso Brown Phenolic Plywood 19mm

- Elegant espresso finish

- Superior strength and durability

- Easy to customize and cut

- Resilient to wear and tear

- Perfect for decorative and functional use.

Light Brown Phenolic Plywood 18mm

- Natural finish enhances decor

- Durable and dependable

- Suitable for various projects

- Easy to work and shape

- Maintains form under pressure.

Vehicle and Marine Construction

Transportation and marine industries require materials that maintain dimensional stability in harsh environments. Bus and trailer manufacturers specify phenolic plywood for flooring applications where moisture exposure and temperature fluctuations are constant challenges. Boat builders use it for bulkheads and wall linings where traditional materials would fail.

Anti-slip variants provide passenger safety on steps and deck surfaces. The material’s resistance to salt water and UV exposure makes it ideal for marine applications. Vehicle floor installations benefit from the easy cleaning properties and resistance to chemical spills that occur during transport operations.

Thick Anti-Slip Birch Plywood 18mm

- Enhanced grip for safe use

- Highly durable and rigid

- Resistant to weather conditions

- Suitable for various applications

- Long-lasting quality and reliability.

DIY, Custom Carpentry, and Home Projects

Home workshop enthusiasts find phenolic plywood perfect for projects requiring moisture-resistant surfaces. Utility room shelving, home gym equipment, and garage storage solutions benefit from the material’s durability and professional appearance. The ready-to-use smooth surface eliminates preparation time for many finishing applications.

Creative DIY projects take advantage of the material’s workability with standard tools. Custom carpentry applications appreciate the consistent quality and reliable grading standards. Home builders often choose this material for areas where moisture exposure is a concern but appearance remains important.

Compact Light Brown Phenolic Plywood 12mm

- Rich light brown color

- Robust and long-lasting

- Versatile for diverse applications

- Easy to cut and finish

- Excellent resistance to moisture.

Performance Benefits and Market Trends for 2026

Sustainability concerns drive increased adoption of phenolic plywood in 2026 construction projects. The material’s reusability factor aligns with eco-conscious building practices that prioritize waste reduction. Modular construction methods particularly benefit from panels that can withstand multiple assembly and disassembly cycles.

Performance statistics demonstrate water absorption rates below 10% after 24 hours, compared to much higher rates for standard plywood. Dimensional change under moisture conditions typically remains under 2%. Surface hardness measurements of 25-45 N/mm² provide excellent resistance to impact and abrasion damage.

Industry certifications continue emphasizing formaldehyde emission controls and responsible sourcing practices. FSC and PEFC certifications become increasingly important for projects requiring environmental compliance. Laminated wood products compete in similar markets but often lack the chemical resistance properties that phenolic coatings provide.

Best Practices and Buying Considerations

Proper edge sealing maximizes panel longevity in moisture-prone applications. Cut edges require waterproof paint or tape to maintain the material’s protective properties. Storage recommendations include keeping panels flat and elevated off ground surfaces in well-ventilated areas.

Certification requirements vary by application, with structural uses requiring EN 636 or EN 314-2 compliance. Standard panel sizes of 1220x2440mm (4’x8′) accommodate most project needs. Thickness options from 12mm to 18mm cover the majority of applications, with specialty grades available for specific requirements.

Quality considerations include checking for consistent film adhesion and proper core construction. Reputable suppliers provide material certificates and performance data to verify specifications. Project planning should account for the material’s premium cost compared to standard plywood, balanced against its extended service life and reduced maintenance requirements.

FAQs

What Is Phenolic Plywood Used For?

Phenolic plywood is used for applications that require durable and moisture-resistant surfaces. It is commonly employed in industrial settings, including formwork for concrete, trailer floors, and any situation where washable, non-slip surfaces are essential.

How Is Phenolic Plywood Different From Regular Plywood?

Phenolic plywood differs from regular plywood because it is coated with a phenolic resin film, making it more resistant to moisture, scratches, and chemicals. This coating also provides a non-slip surface, ideal for many industrial and construction uses.

Can Phenolic Plywood Be Used Outdoors?

Yes, phenolic plywood can be used outdoors. Its moisture-resistant properties make it suitable for outdoor use, especially in applications where weather resistance and durability are crucial, such as outdoor furniture and construction formwork.

What Are The Benefits Of Using Phenolic Plywood?

The benefits of using phenolic plywood include its high resistance to moisture, chemicals, and wear and tear. It provides a strong, durable, and long-lasting surface, ideal for heavy-duty applications. Additionally, its non-slip coating ensures safety in environments where traction is important.

How Do You Cut And Finish Phenolic Plywood Effectively?

To cut and finish phenolic plywood effectively, use carbide-tipped blades to handle its tough coating. Sealing the cut edges with a waterproof sealant is recommended to maintain its moisture resistance. Sanding may be necessary to smooth any rough edges after cutting.