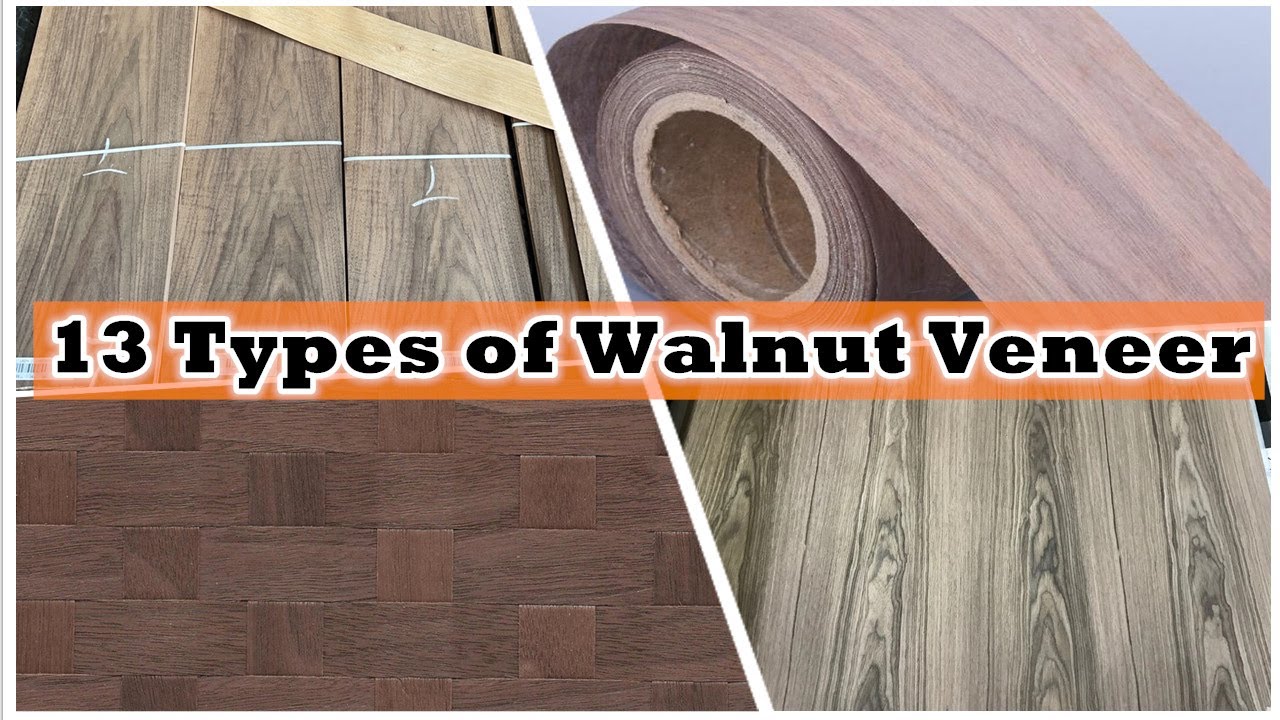

Veneer Walnut Wood: 5 Best Choices Today

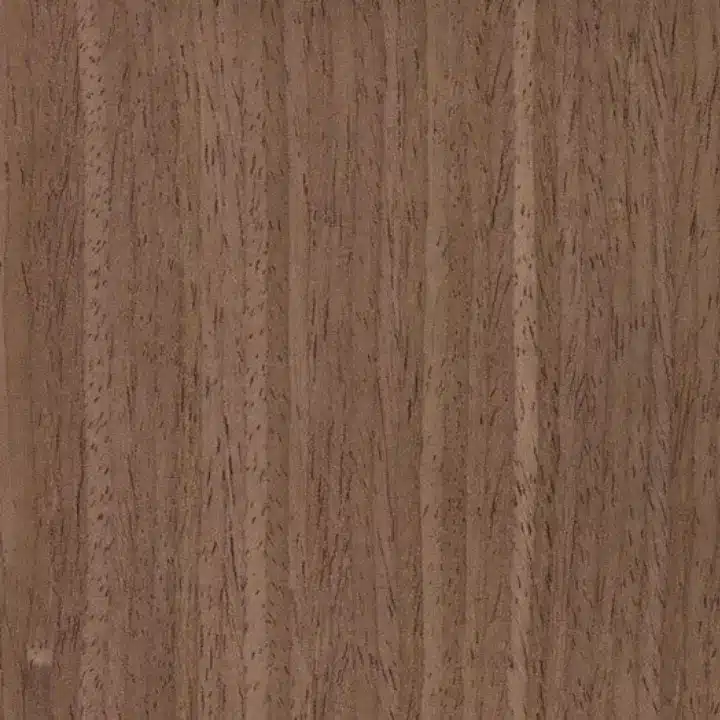

Ever looked at a piece of furniture and wondered why it looks so elegant and rich? The secret might be in the veneer walnut wood used. Known for its deep brown tones and unique grain patterns, this type of wood gives any project a timeless elegance. Let’s explore the top choices available today and help you find the perfect fit for your next project!

Table of Contents

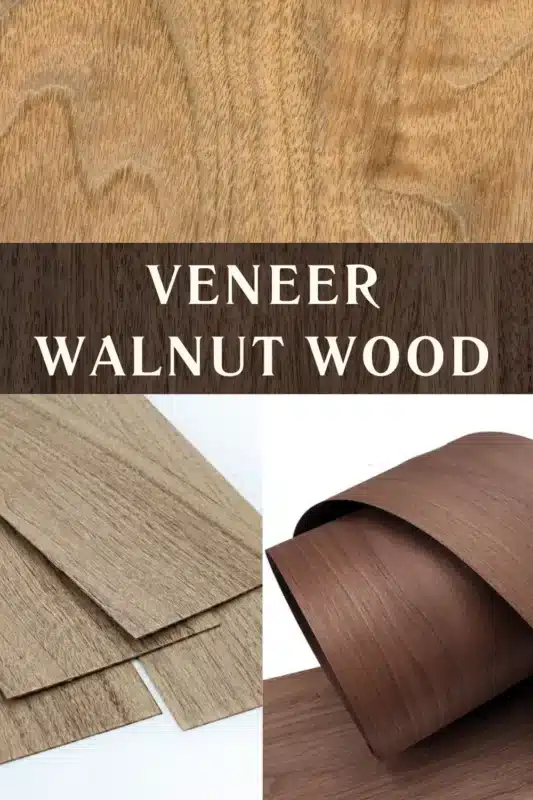

Veneer walnut wood represents one of the most sought-after decorative materials in modern woodworking, featuring rich brown hues and distinctive grain patterns that make it a top choice among designers and craftspeople. This thin-layered wood solution offers the natural beauty of walnut at a fraction of the cost of solid lumber, with natural wood veneers comprising nearly 60% of the overall veneer market according to JSO Wood Products.

Types of Veneer Walnut Wood Explained

Different cutting methods and manufacturing processes create distinct types of walnut veneer, each offering unique characteristics for specific applications. The choice between these varieties depends on your project’s aesthetic goals, budget constraints, and functional requirements.

Plain Sliced Walnut Veneer (Flat Cut)

Plain sliced walnut veneer showcases broad, sweeping “cathedral” grain patterns that create an elegant, traditional appearance. This cutting method produces the most recognizable walnut grain pattern, making it the preferred choice for classic furniture and cabinetry projects where visual impact matters most.

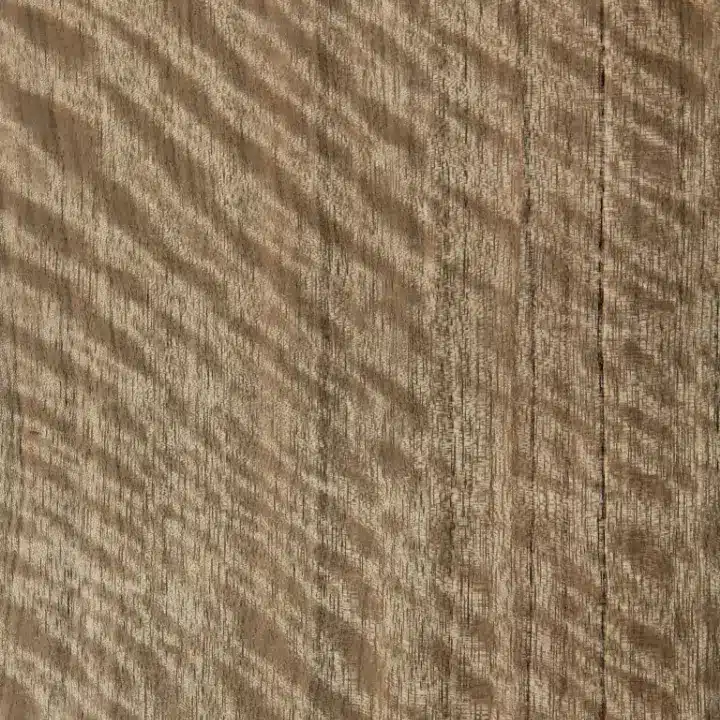

Quarter Sawn Walnut Veneer

Quarter sawn walnut veneer features tight, straight grain with a uniform appearance that appeals to modern design sensibilities. This premium cutting technique produces consistent grain patterns across panels, making it ideal for high-end furniture where uniformity and refined aesthetics are priorities.

Figured Walnut Veneer

Figured walnut veneer includes dramatic patterns like curly, wavy, crotch, and burl formations that create stunning visual effects. Each sheet offers unique characteristics, making figured veneer perfect for statement pieces, decorative inlays, and focal points in furniture design.

Reconstituted (Engineered) Walnut Veneer

Reconstituted walnut veneer uses real wood fiber that’s dyed and reconstructed to ensure consistent color and grain from sheet to sheet. This engineered approach eliminates natural defects and length waste, making it perfect for large commercial projects requiring uniformity across multiple panels.

Specialty-Backed Walnut Veneers

Specialty backing materials enhance veneer performance and application flexibility. Fleece-backed veneers offer durability and flexibility for curved surfaces, while paper-backed options provide full panel coverage at significantly reduced costs compared to traditional sheets.

Top 5 Best Veneer Walnut Wood Choices for 2025

Selecting the right walnut veneer depends on your specific project requirements, budget, and aesthetic preferences. Here are the five best options that cover different needs and applications in today’s market.

Choice #1: Plain Sliced Walnut Veneer

Plain sliced walnut veneer remains the most popular choice for traditional furniture and cabinetry projects. Its cathedral grain pattern provides classic elegance that works well in both residential and commercial applications, available in various sizes and thicknesses to match project specifications.

Choice #2: Quarter Sawn Walnut Veneer

Quarter sawn walnut veneer offers straight, uniform grain patterns perfect for clean, modern finishes. This premium option commands higher prices due to the specialized sawing technique but delivers exceptional results for luxury and minimalist design projects.

Choice #3: Figured Walnut Veneer (Burl, Crotch, Curly)

Figured walnut veneer creates visually striking focal points with its natural patterns and unique characteristics. Each sheet displays different features, making this option rare and premium-priced but perfect for statement pieces and decorative applications.

Choice #4: Reconstituted (Engineered) Walnut Veneer

Reconstituted walnut veneer provides uniform appearance and cost-effectiveness for large-scale projects. This engineered solution eliminates natural wood variability, making it ideal for commercial installations requiring consistent color and pattern matching across multiple panels.

Choice #5: Specialty Backed Veneers (Fleece and Paper)

Specialty backed veneers offer enhanced functionality and cost savings. Fleece-backed options provide flexibility for complex profiles and curves, while paper-backed sheets deliver high coverage at 60% cost savings compared to traditional veneer options.

Best Veneer Walnut Wood Products on Amazon

These top-rated walnut veneer products offer convenient solutions for DIY enthusiasts and professionals alike.

Peel & Stick Walnut Veneer Sheet

- Effortless peel and stick application

- Smooth finish enhances any surface

- Perfect for furniture restoration and DIY projects

- Durable A grade veneer for long-lasting use

- Versatile size fits most cabinetry needs

Easy-to-Apply Walnut Veneer Sheet

- Self-adhesive for simple application

- Perfect for large surfaces with 96-inch length

- Premium A grade veneer for professional results

- Enhance furniture effortlessly

- Ideal for DIY enthusiasts and professionals

Extra Wide Black Walnut Veneer

- Extra-wide size for diverse applications

- High-quality appearance for stunning finishes

- Perfect for guitars and speaker projects

- Durable and easy to work with

- Great for furniture refurbishment and décor

Compact Walnut Veneer Set

- Comes in a convenient 7-piece set

- Compact size suitable for small projects

- High-quality walnut for an elegant finish

- Perfect for artistic and craft applications

- Easy to handle and cut for customization

Iron-on Walnut Wood Edgebanding

- Preglued with hot melt adhesive for easy application

- Flexible and adaptable wood tape

- Perfect for a smooth finish on edges

- Enhances furniture and cabinetry looks

- Suitable for both DIY and professional use

Popular Applications and Market Trends

Walnut veneer finds extensive use across multiple industries and applications. High-end furniture manufacturing represents the largest market segment, followed by luxury cabinetry and architectural millwork projects that demand premium aesthetics.

- Feature wall panels and architectural millwork installations

- Restoration projects requiring period-appropriate materials

- Interior design detailing for luxury residential construction

- Commercial furniture and hospitality industry applications

Market data from JSO Wood Products shows that natural wood veneers make up nearly 60% of the overall veneer market. Demand continues increasing in high-end residential construction where black walnut wood and other premium species create distinctive design statements.

Key Considerations When Choosing Veneer Walnut Wood

Several factors influence the selection of appropriate walnut veneer for your project. Understanding these considerations helps match the right product to your specific needs and budget constraints.

Consistency vs. Uniqueness

Engineered veneers provide uniformity across large projects, eliminating natural variations that might disrupt design continuity. Natural varieties offer unique grain patterns on every sheet, perfect for projects where individual character and distinctive appearance matter more than consistency.

Durability and Application Factors

Backed veneers significantly increase lifespan and performance, particularly for curved surfaces and high-use applications. Thickness and backing material choices affect both installation methods and long-term durability, with fleece backing offering superior flexibility for complex shapes.

Price and Quality Factors

Wood source, grain quality, and finishing processes directly impact veneer pricing. Budget considerations should balance initial costs against long-term performance, with premium options often providing better value for high-visibility applications where quality matters most.

Environmental Benefits and Cost Advantages

Veneer walnut wood offers significant environmental and economic advantages over solid wood alternatives. Resource efficiency maximizes valuable walnut usage through thin layers, reducing waste compared to traditional solid wood construction methods.

Sustainability benefits include reduced forest pressure and waste minimization during manufacturing. Wooden Ave reports that paper-backed sheets offer over 60% cost savings compared to traditional options, making premium walnut aesthetics accessible for budget-conscious projects.

- Maximized usage of valuable walnut resources through efficient cutting

- Reduced environmental impact compared to solid wood harvesting

- Cost-effective access to premium walnut aesthetics

- Support for eco-conscious building and furniture manufacturing

These advantages make walnut veneer an attractive option for projects requiring premium aesthetics while maintaining environmental responsibility. The cost savings enable broader access to walnut’s distinctive beauty across various types of wood for furniture applications.

Making the Right Veneer Walnut Wood Choice

The five best veneer walnut wood options each serve specific project needs and budget requirements. Plain sliced veneer works best for traditional applications, while quarter sawn varieties suit modern, minimalist designs requiring grain consistency.

Figured veneers create dramatic focal points but command premium prices due to their rarity. Reconstituted options provide cost-effective uniformity for large projects, while specialty-backed veneers offer enhanced performance for challenging applications requiring flexibility or maximum coverage.

Match your veneer choice to project requirements by considering aesthetic goals, budget constraints, and performance needs. Whether you’re working on furniture restoration, architectural millwork, or modern cabinetry, the right walnut veneer selection will deliver both beauty and functionality for years to come.

FAQs

What Are The Benefits Of Using Walnut Veneer For Furniture?

Walnut veneer offers a beautiful, rich finish to furniture at a more affordable price compared to solid walnut. It’s lightweight, making it easier to work with and more adaptable to various design styles while providing a high-quality appearance.

How Does Walnut Veneer Compare To Solid Walnut Wood?

While solid walnut offers durability and the ability to be refinished multiple times, walnut veneer provides a cost-effective alternative that maintains the aesthetic appeal of solid wood. Veneers are also less susceptible to warping and splitting.

Is Walnut Veneer Durable And Sustainable?

Walnut veneer is durable when properly maintained and offers a sustainable choice as it uses less wood compared to solid lumber. Many manufacturers source their veneers from sustainably managed forests.

How Can I Maintain And Clean Walnut Veneer Surfaces?

To maintain walnut veneer, dust regularly with a soft, dry cloth and clean using a damp cloth with mild soap if needed. Avoid excess water and harsh chemicals, as they can damage the veneer finish.

What Is The Cost Difference Between Walnut Veneer And Other Wood Veneers?

Walnut veneer tends to be more expensive than common veneers like oak or maple but is often less costly than exotic wood veneers. Its price is generally determined by the quality and rarity of the veneer.