Top 10 Soft Wood Picks: From Balsa to Basswood

Which soft wood is best for carving, models, or outdoor work? Softness changes how easy wood is to cut, sand, and shape. This post looks at ten popular soft woods like balsa and basswood. Read on to see their key traits and common uses so you can choose the right wood for your project.

Table of Contents

Soft wood covers conifer-based timbers that are light, easy to work, and widely used in building, crafts, and instruments. This guide explains key properties, the Janka scale, and the best softer woods for each project.

What Makes Wood “Soft”? Understanding Softwood Basics

Softwood usually comes from conifers and tends to grow fast, mill cleanly, and cost less per board foot. You’ll pick it for framing, siding, trim, and many craft jobs where easy cutting matters.

Coniferous vs. Deciduous Origins

Conifers (gymnosperms) give us pine, fir, spruce, cedar, and hemlock—these are classic softwood species. Deciduous trees (angiosperms) are “hardwoods,” yet craft favorites like basswood are botanically hardwood but work like a soft wood in carving; compare with poplar wood as another friendly option for beginners.

If you’re new, focus on tree type, workability, and project needs rather than labels alone; a “hardwood” like basswood can still be the softest woods choice for carving. For a concise overview of common softwoods and uses, see AtoZ Wood Company: Types of Softwood.

Janka Hardness Scale Explained

The Janka scale measures how much force it takes to embed a 0.444-inch steel ball halfway into wood, which helps compare dent resistance. Most softwoods sit between roughly 300–700 lbf, while balsa is far lower, so plan for gentle handling and protective finishes on very soft wood.

Janka hardness is a practical indicator of a wood’s wear and dent resistance in flooring, furniture, and construction.

Industry testing standard

| Species | Janka Hardness (lbf) | Typical Use |

|---|---|---|

| Balsa | 67 | Models, cores, crafts |

| Paulownia | ~300 | Surfboards, light furniture |

| European Silver Fir | ~320 | Joinery, interiors |

| Eastern White Pine | ~380 | Millwork, boats |

| Hemlock | ~500 | General construction |

| Douglas Fir | ~620 | Beams, trusses, bridges |

| Southern Yellow Pine | 870–1,225 | Decking, poles, marine |

Key Properties of Softer Woods

Look for low density, straight grain, and good workability if you need easy cutting and gluing. Many softwoods accept nails and screws well but benefit from pre-drilling and a protective finish to reduce denting and moisture uptake.

1. Balsa Wood – The World’s Softest Commercial Wood

Balsa is extremely light, with the lowest common Janka rating of any commercial timber. Makers favor it for fast prototyping and models where weight savings matter most.

Ultra-Light Properties

Typical density is a fraction of most softwoods, and its Janka value sits around 67 lbf per published charts. Check thickness and grain quality before laser cutting or laminating, and use sealing coats to protect the soft fibers from dents; see the hardness ranking in 75 Types of Wood Ranked by Janka Hardness.

Primary Applications

Use balsa for RC aircraft, architectural models, sandwich cores with fiberglass or carbon, fishing lures, and instrument prototypes; our balsa wood guide covers sizing and gluing tips. For thin-sheet model work, these sheets are handy

Balsa Wood Sheets 1/16-inch (12 x 4) Pack of 6

- Ultra-thin 1/16-inch sheets for delicate model work

- Lightweight and easy to cut with hobby knives

- Smooth surface ready for painting, gluing, or sealing

- Consistent thickness ideal for laser cutting and crafting

- Versatile for models, prototypes, and art projects

2. Paulownia – The Fast-Growing Wonder Wood

Paulownia is a very light soft wood that machines cleanly and resists warping better than many comparably light species. Craftspeople pick it for surf craft, trim, and light furniture.

Dimensional Stability

Boards move less across the seasons thanks to low density and friendly grain, so panels and frames stay straight with basic sealing. Pre-seal end grain, use balanced laminations, and keep finishes thin to preserve its weight advantage.

Surfboard Construction

Shapers like paulownia for stringers and skins because it’s light, strong for its mass, and finishes smooth under glass. Compared with balsa, paulownia often needs less sealing and holds edges well after final sanding.

3. European Silver Fir and Western Red Cedar

European silver fir offers uniform grain for clean joinery, while Western red cedar brings aroma and natural resistance that suit exterior parts. Both are light, machine well, and accept finishes without fuss.

Natural Decay Resistance

Cedar heartwood contains natural compounds that deter moisture and insects, making it a go-to for siding and shingles. Silver fir is less resistant than cedar, so add a quality sealer or paint for longer service life.

Outdoor Applications

Pick cedar for decks, pergolas, planters, and sauna interiors where low weight and weather resistance help. Learn more about species choice in our cedar wood resource for cladding and fencing.

4. Eastern White Pine and Maritime Pine Varieties

Eastern white pine is a classic North American softwood prized for easy hand-tool work. Maritime pine from Western Europe brings reliable stock for paneling, light framing, and millwork.

Traditional Woodworking Uses

Use white pine for casework, doors, trim, and painted furniture where a smooth, knot-minimized face saves time. Maritime pine planes cleanly, stains evenly with a pre-conditioner, and takes fasteners well with pre-drilled pilot holes.

Boat Building Applications

Builders use white pine for planking, spars, and interior joinery on small craft; coat with epoxy or marine varnish for durability. Maritime pine serves in non-structural parts and brightwork where light weight and easy shaping help.

5. Basswood – The Carver’s Choice

Basswood is technically a hardwood, yet it’s a go-to soft wood for knives and gouges because it carves like soap. Beginners and pros value its clean cuts and predictable results.

Fine Grain Structure

The fine, even grain holds crisp detail with minimal tear-out, so undercutting and delicate textures come out clean. Keep blades razor sharp, and use light passes to avoid compressing the soft earlywood bands in this softer woods favorite.

Musical Instrument Making

Electric guitar bodies, blocks for luthier jigs, and lightweight instrument parts often use basswood for its uniform machining. It takes paint and clear coats smoothly, giving a stable base for finishing and hardware.

For carvers and whittlers, these curated basswood kits make practice and gifting easy.

19-Piece Basswood Whittling Block Kit

- Three different block sizes for varied projects

- Soft, fine-grain basswood that carves smoothly

- Ideal for beginners and kids as well as experienced carvers

- Easy to sand, paint, and finish for custom projects

- Great for toys, miniatures, and practice pieces

12-Pack Basswood Carving Blocks (4 x 1 x 1 in)

- Uniform 4x1x1 inch blocks for repeatable projects

- Soft basswood with fine grain for easy carving

- Unfinished surface ready to sand, paint, or stain

- Great for beginners, classes, and detailed carving

- Handy for charms, figurines, and practice pieces

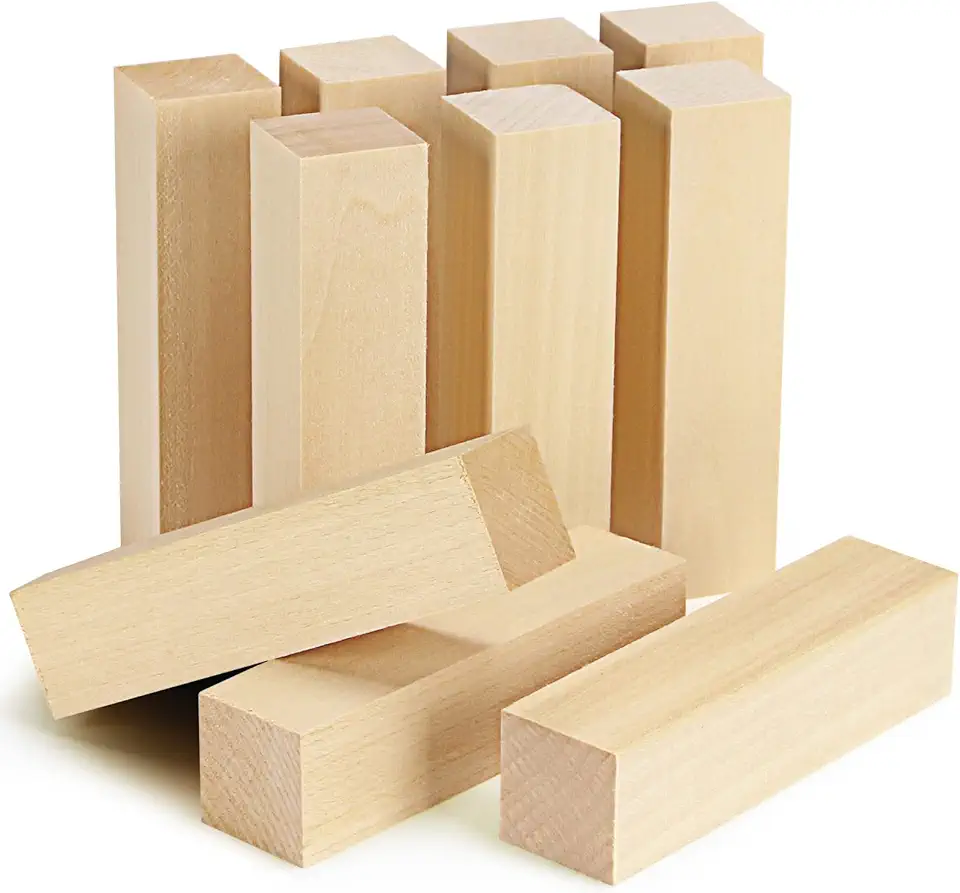

10-Pack Basswood Blocks for Whittling (4 x 1 x 1)

- Soft, easy-to-shape basswood ideal for whittling

- Consistent sizing for predictable results

- Unfinished blocks perfect for custom finishes

- Suitable for both beginners and experienced carvers

- Great for small sculptures, ornaments, and experiments

6. Spruce and Hemlock – Construction Staples

Spruce and hemlock form a big part of “SPF” framing lumber due to consistent strength-to-weight ratios. They plane fast, nail cleanly, and glue well with common PVA or polyurethane adhesives.

Structural Applications

Use them for studs, joists, trusses, and sheathing where straight grain supports predictable loads. For typical hardness ranges and species profiles, check Types of Softwood for quick reference before ordering softwood planks.

Resonant Wood Properties

Spruce is famous for soundboards thanks to high stiffness-to-weight and a clear, ringing tap-tone. Luthiers seek straight, even grain with narrow growth rings for better resonance and stability.

7. Douglas Fir and Southern Yellow Pine – Stronger Softwoods

Douglas fir combines straight grain with high stability, while Southern yellow pine ranks among the hardest softwoods. Both carry higher Janka numbers than most conifers and suit heavy-duty projects.

Bridge Construction

Douglas fir glulam beams and decking assemblies handle long spans with predictable performance, especially in covered settings. For hardness references and structural notes by species group, see Janka Hardness Rankings before specifying members.

Marine Timber Uses

Pressure-treated Southern yellow pine performs in piers, bulkheads, and freshwater docks, while Douglas fir excels in boat frames and mastwork. Explore species pages for Douglas fir and yellow pine when choosing finishes and fasteners.

Choosing the Right Soft Wood for Your Project

Match species to your tools, environment, and the abuse the part will see, then pick a protective finish that fits. Keep weight, hardness, moisture exposure, and availability in mind before you cut.

Carving and Crafts

Basswood is the top pick for detail work; balsa rules for models; cedar is nice for burning and rustic decor. Start with sharp knives, light cuts, and a thin shellac or poly seal to protect soft fibers.

- Basswood: best for whittling and fine detail with minimal tear-out.

- Balsa: best for ultra-light models, prototypes, and laser-cut parts.

- Paulownia: great for surf craft, trim, and light furniture panels.

- Cedar: ideal for outdoor decor and projects needing natural resistance.

- Spruce: pick for musical soundboards and lightweight frames.

Construction Applications

Use SPF (spruce-pine-fir) for studs and trusses; step up to Douglas fir for beams and long spans; choose Southern yellow pine where higher hardness and treated options matter. For cladding and outdoor trim, Western red cedar keeps weight low and offers decay resistance.

Sustainability Considerations

Many softwoods grow quickly and fit well in managed forests; look for FSC or PEFC labels and buy regionally to reduce transport impact. The USDA Forest Service shares guidance on responsible forestry practices that support renewable wood supply.

For project-ready packs in softer species, these options are easy to store and quick to use.

BeaverCraft 18-Piece Basswood Carving Block Set

- High-quality soft basswood for smooth carving results

- Two block sizes for versatility in projects

- Unfinished wood ready for carving, painting, or staining

- Ideal for beginners learning techniques and pros refining details

- Consistent, usable blocks for crafts and repairs

Basswood Carving Starter Set with Carry Case

- Portable case keeps blocks organized and protected

- Soft basswood blocks made for easy carving

- Great starter kit for new carvers and hobbyists

- Blocks sand and paint smoothly for finished projects

- Convenient for classes, travel, and on-the-go crafting

18-Pack Basswood Squares 6 x 6 (1/16 inch)

- Pre-cut 6x6-inch squares with uniform 1/16-inch thickness

- Smooth surface ideal for drawing, burning, or painting

- Lightweight balsa/basswood suitable for laser cutting and engraving

- Easy to trim and glue for model building

- Perfect for crafts, prototypes, and hobby projects

FAQs

What Is The Best Soft Wood For Furniture Making?

Pine Is Often Considered The Best Soft Wood For Furniture Because It’s Readily Available, Affordable, And Easy To Work With; It Takes Stain And Paint Well. For More Durable Or Outdoor Pieces, Cedar Or Redwood Are Better Choices Due To Their Natural Rot Resistance. Choose Kiln-Dried, Straight-Grained Boards And Match The Wood To Your Project Needs.

How Can I Tell The Difference Between Soft Wood And Hard Wood?

You Can Tell Softwood From Hardwood By Botanical Source (Softwoods Come From Conifers), By Density And Weight, Grain Pattern, And End-Grain Pores—Hardwoods Usually Show Distinct Vessel Pores. Practical Tests Include The Janka Hardness Rating, Feeling The Weight, Or Looking At The End Grain Under Magnification.

Are Soft Woods Suitable For Outdoor Projects?

Some Softwoods Are Suitable Outdoors When They Are Naturally Durable (Like Cedar Or Redwood) Or Properly Treated (Pressure-Treated Pine). To Ensure Longevity, Use A Weather-Resistant Finish, Provide Good Drainage And Airflow, And Reapply Sealers Or Stains Regularly.

What Are The Advantages Of Using Soft Wood In Construction?

Softwoods Offer Lower Cost, Lighter Weight, Ease Of Cutting And Fastening, And Quick Availability Due To Faster Growth Cycles, Making Them Cost-Effective And Often More Sustainable. They Also Provide Good Thermal Insulation And Are Easier To Repair, Though They May Require Treatment For Long-Term Durability.

How Do I Properly Maintain And Care For Soft Wood Furniture?

Maintain Soft Wood Furniture By Dusting Regularly With A Soft Cloth, Wiping Spills Immediately, Avoiding Direct Sunlight And Extreme Humidity, And Using Coasters Or Pads. Periodically Refinish With Oil, Wax, Or Varnish As Needed, Sand Out Scratches Before Recoating, And Store Indoors Or Under Cover When Not In Use.