Luan Plywood Guide: What It Is, Uses, and 1/4-Inch Specs

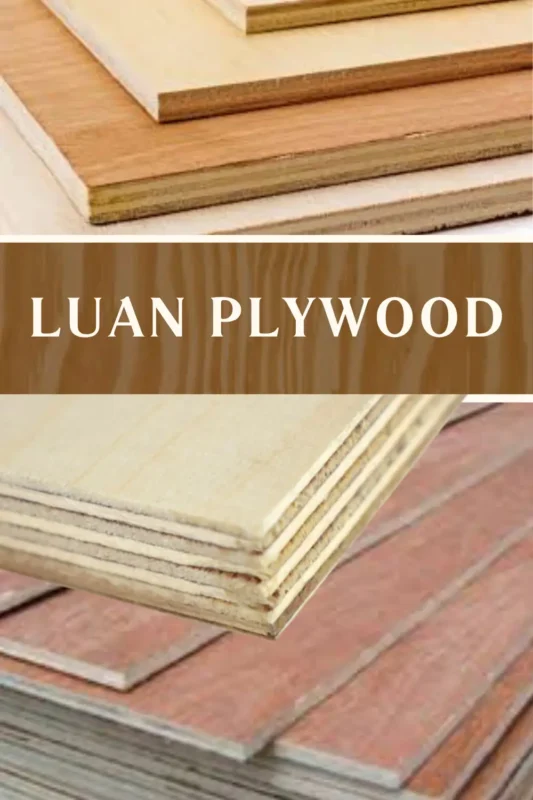

Luan plywood is a thin, lightweight tropical hardwood plywood (often sold as lauan) made from Shorea species, usually used indoors for smooth panels, cabinet backs, and underlayment. People choose it for a smooth face and easy cutting, but it’s not structural and it can warp or swell if it gets wet.

Table of Contents

If you’re here for specs, 1/4 luan plywood is commonly sold in 4×8 sheets at about 4 mm actual thickness, usually weighing in the mid-teens per sheet, and it works best where you need a flat skin—not strength.

What Is Luan Plywood

Luan (also spelled lauan) is a trade name for thin tropical hardwood plywood made from several related Shorea trees, often marketed as “Philippine mahogany” even though it isn’t true mahogany. The big tell in use is the light weight: you can carry a 4×8 sheet one-handed, and it makes a slightly hollow “papery” knock compared with denser cabinet panels.

Sellers typically position it as an interior panel with a smooth rotary-cut face that takes paint quickly and sands fast. For a quick background definition and common retail labeling, see What is Luan Plywood?.

Names and species

You’ll see lauan, luan, and “Philippine mahogany” used interchangeably on tags, which trips beginners up when they expect one exact wood. In practice, luan usually groups Shorea species that fall under Meranti in the lumber trade, and the face can vary from pale tan to pinkish red depending on the batch.

That species mix affects results: some sheets sand buttery-smooth, while others have interlocked grain that “fuzzes” under 120–150 grit and needs a sharper sanding sequence. If you need a predictable paint surface, I’ll often step up to a more consistent panel, then save luan for hidden parts where color match doesn’t matter.

Typical thickness and sizes

Luan commonly shows up in thin sheets like 1/8″ (about 3 mm) and 1/4″ (often about 4 mm actual), because it’s mainly sold as a skin material, not a structure. Standard panels are usually 4×8 (1220×2440 mm), though you’ll also run into 1200×2400 mm in some supply chains.

Those thin formats are also why it’s easy to get fooled by a panel that looks flat at the store but “potato-chips” after you bring it into a heated shop. If you’re sorting sheets, sight down the long edge, then flex the corners lightly; a sheet that springs back evenly tends to behave better once installed.

Origins and manufacturing

Luan plywood is typically made by rotary peeling logs into thin veneers, then cross-laminating layers with interior-grade adhesives. Rotary faces look wide-grained and “flowy,” and under a bright shop light you can often see cathedral grain patterns that read like a budget mahogany substitute.

The trade-off is that thin veneers and mixed species can create thickness swing and occasional core voids, which matter if you’re routing joinery or laminating floors. If you want a quick refresher on reading panel labels and what that usually implies, this guide on plywood grades helps you decode what “utility” often means in real use.

Types of Luan Plywood

Luan isn’t one uniform product; it’s more like a category that shifts by supplier and shipment. In the same week, I might see one bundle that bends cleanly for curved work and another that snaps at the first tight radius because the face veneer is brittle and the core has grain runout.

Meranti variants

Many luan panels fall under Meranti groupings such as Light Red, Dark Red, Yellow, or White Meranti. In practical shop terms, “lighter” sheets often paint more evenly, while darker red sheets can look richer under clear finish but may blotch if you go straight to stain without a sealer.

A common mistake is assuming two sheets labeled luan will match as a pair for cabinet door panels. If color match matters, open the stack and select consecutive sheets, then keep them face-to-face during acclimation so both sides see similar humidity.

Color and grain

Luan’s face can run from pale straw to a warm reddish brown, usually with a shimmer when you tilt it under light because the rotary cut changes grain direction across the sheet. When you sand it, the dust feels finer than construction plywood, but the face can still “tear” if you use a dull blade or push too fast.

If you’re clear-coating, do a quick wipe with mineral spirits to preview the final look; it’s the fastest way to spot patchy veneer or glue smear that will jump out after finish. For projects where face appearance is the main goal, I’ll often compare it against alternatives like maple plywood and pick based on how much finishing time I can afford.

Common thicknesses

The most common luan thicknesses are 3 mm (about 1/8″) and 4 mm marketed as 1/4″, with thicker panels appearing less often. Thin luan bends more easily for skins and curved forms, but it also telegraphs bumps underneath, so prep work on the substrate matters more than most people expect.

Watch for a beginner trap: mixing nominal and metric stock in one build. A “1/4-inch” luan panel that’s really 4 mm paired next to true 1/4″ material can leave a visible step at seams, especially under glossy paint.

Key Properties of Luan Plywood

Luan’s performance comes down to three things: low density, thin plies, and a face veneer that’s made for looks more than abuse. In hand tools, it feels “easy” in the cut—then punishes you with splinters if you don’t support the fibers on the exit side.

Weight by thickness

For planning transport and wall installs, weight matters more than most specs sheets admit. A 4×8 sheet is light enough to maneuver solo, but that same lightness often signals less stiffness, which means you need more fastening points or a flatter substrate.

| Nominal thickness | Typical actual thickness | Typical 4×8 sheet weight | What it feels like in use |

|---|---|---|---|

| 1/8″ | ~3 mm | ~10–12 lb | Very flexible; easy to crease if you carry it flat |

| 1/4″ | ~4 mm (often) | ~14–16 lb | Still flexible; needs support to stay flat |

Expect variation by shipment and moisture level; I’ve weighed sheets that swing enough to change how they hang on a wall. If you need planning numbers for other panels, this internal guide to plywood weight helps you compare materials before you load the truck.

Surface and finish

Luan’s face is usually smooth right out of the stack, which is why it’s popular for quick paint jobs and as a skin over frames. When I run a palm across a fresh sheet, it feels slick but not glassy; you can still sense tiny open pores that will drink primer if you skip a sealing step.

Common mistake: sanding straight through the face veneer at edges and corners. Use a sanding block on edges, stop around 180–220 grit for paint, and seal end grain with primer or shellac so you don’t get fuzzy edges after the first coat.

Flex and stability

Thin luan can bend into gentle curves, which makes it handy for soffits, curved cabinet skins, and templates. That same flexibility also means it can “oil-can” (pop in and out) if it’s fastened too far apart or if one side sees more humidity than the other.

The fix is boring but reliable: fasten closer, glue when appropriate, and finish both sides when appearance allows. If you’re building panels where flatness matters, I’ll often pick a different sheet good from the start—luan can behave, but it doesn’t give you the same predictable flat panel-to-panel consistency.

Pros and Cons of Luan Plywood

Luan rewards you when you treat it like what it is: a finish surface and lightweight skin. It disappoints when you ask it to act like structural plywood or expose it to moisture.

Main pros

- Lightweight panels are easier to lift, tack in place, and trim.

- Smooth face usually needs less prep than construction plywood for paint.

- Easy cutting with common saw blades (with the right support).

- Flexible thin sheets work for curves, skins, and templates.

- Lower cost than many cabinet-grade hardwood plywood.

Main cons

The biggest drawbacks are moisture sensitivity, variable cores, and thin face veneer that’s easy to damage. I’ve seen beginners install it as a “quick wall panel” in a slightly damp basement, then watch seams swell and ridges print through paint within weeks.

Splintering is another frequent pain point: crosscuts can leave a prickly edge that feels like tiny needles when you wipe dust off with your hand. Use a sharp blade, add painter’s tape over cut lines, and support the exit side with a backer to reduce tear-out.

Common Uses for Luan Plywood

Luan shines on interior work where you want a clean look without hauling heavy panels. It’s also a go-to when you need a disposable pattern material that still cuts cleanly enough to trace repeatedly.

Cabinets and furniture

Luan is common for cabinet backs, dust panels, drawer bottoms, and lightweight furniture skins. It’s a good fit when the panel is supported on all sides; it’s a poor fit for long unsupported spans, where it can sag and start to rattle when you close doors.

If you’re building anything “nice” that will see wear, don’t confuse luan with cabinet-grade hardwood plywood. For that, compare your options with cabinet grade plywood so you know what you’re paying for in veneer thickness and core quality.

Walls and ceilings

For walls and ceilings, luan works as a painted panel over furring strips or a flat substrate, especially when weight matters. The key is fastening density: spread-out nails can let the panel drum or bow, and you’ll hear a faint “thunk” when you tap it as it separates from the backing.

A common mistake is installing sheets straight from a cold garage into a warm room. Stack them flat indoors for a couple days, then install; that acclimation reduces seam creep where joints open or ridge after temperature swings.

Crafts and templates

Luan is excellent for templates, patterns, mockups, and craft builds where you want a smooth face that marks well with pencil. It laser-cuts and CNC-cuts, but batch variability can affect kerf and fit; if your slots are tight, test-cut and adjust because luan can vary fractions of a millimeter sheet to sheet.

If you need cleaner edges and fewer void surprises for precision parts, I’ll often shift to birch panels. Here’s a quick video that helps visualize handling and panel behavior before you commit to a stack.

Flooring underlayment

1/4 luan plywood is often used as underlayment under vinyl, laminate, or carpet where you need a smoother surface than the subfloor provides. The feel test is simple: drag a putty knife across seams; if the knife “ticks,” that ridge can telegraph through thin flooring under sunlight.

Two common failures show up here: swelling from moisture and fastener issues. Avoid using luan over damp slabs or where spills are likely, and don’t staple randomly—use a consistent pattern and set fasteners so you don’t leave raised crowns that print through later; for typical retail descriptions of 1/4″ sheets, see 1/4 4×8 Luan Plywood.

Luan Plywood vs Other Plywood

Luan can be the right choice, but it’s rarely the “one plywood for everything.” I pick based on moisture exposure, stiffness needs, and whether the finish has to look perfect at arm’s length under raking light.

Luan vs CDX

CDX is built for construction: thicker plies, stronger glue lines, and tolerances that assume it’ll be covered up. Luan is built for appearance and light duty; it has a smoother face, but it won’t tolerate weather or jobsite abuse the way CDX does.

If you’re deciding between them for sheathing or anything with moisture risk, pick CDX and keep luan for interior skins. Luan can look great indoors, but it’s the wrong bet anywhere water can reach an edge and wick into the plies.

Luan vs marine plywood

Marine plywood is built to resist water damage with better cores and glue, and it’s priced to match. Luan is usually interior-grade; even a small leak can cause edge swelling, and once it swells, sanding rarely brings back a truly flat panel.

If your project lives near a sink, a shower, a boat, or a humid shop, skip luan and reference this internal guide on marine plywood to match the panel to the environment.

Luan vs Baltic birch

Baltic birch is denser and more consistent, with fewer voids and stiffer layers—great for drawers, jigs, boxes, and CNC parts that need repeatable fit. Luan is lighter and often smoother on the face, but the core can surprise you when you route an edge and hit a soft spot.

If you need small, strong panels for precise work, Baltic birch saves time because you fight less sanding and fewer patch repairs. For a deeper comparison, this internal page on Baltic birch breaks down why it behaves differently in joinery.

2-Pack 12 inch Baltic Birch Sheets 3 mm

- Two 12 by 12 inch B BB grade Baltic birch sheets at 3 mm for strength

- Denser and stiffer than basswood for structural parts

- Smooth faces and clean edges for precise CNC and laser work

- Minimal voids and stable layers for professional finishes

- Ideal for durable models, boxes, and finished pieces

1/4 Luan Plywood Specs and Buying Notes

This is where most “what should I buy” decisions land, because 1/4 luan plywood is the common store format. It’s handy, but you’ll get better results if you shop with calipers, a straightedge, and a plan for how you’ll treat seams and edges.

Nominal vs actual thickness

“1/4 inch” is often nominal for luan; many sheets come in around 4 mm rather than a true 0.250″. That matters for underlayment transitions, router depth settings, and any dado meant to capture the panel snugly.

Pro workaround: if a groove needs to fit a whole stack of panels, cut the groove to the thickest sheet you measured, then use a thin bead of flexible adhesive or a strip of veneer tape as a shim on thinner sheets. It’s faster than chasing perfect fit on a material that doesn’t hold perfect thickness.

Sheet weight and handling

A typical 4×8 sheet is light enough that you can carry it without strain, but that also means it can crease if you grab it mid-span and let it fold. Carry it on edge, support the middle with your forearm, and keep corners from smacking door frames—those corners crush easily and show through paint.

For clean cuts, I score the face lightly with a knife at the cut line when the job needs a crisp paint edge. That quick step reduces splinter lift on the face veneer, which is the main reason “easy plywood” suddenly looks ragged after trimming.

Typical price range

Expect roughly $20–$40 for a 4×8 sheet of 1/4 luan in many markets, with swings based on import grade, core quality, and how flat the batch is. The cheapest sheet can cost more in labor if you spend an hour filling voids, flattening bubbles, or redoing seams that telegraph through finish.

If you’re comparing sizes and standards across materials, this internal reference on plywood dimensions helps you avoid the common mismatch between 4×8 nominal panels and metric imports.

Best-fit applications

1/4 luan plywood works best as a skin: cabinet backs, drawer bottoms with perimeter support, wall panels over a flat base, and underlayment where moisture is controlled. It’s a poor pick for shelves, spans, or anything that takes screws close to an edge; the thin plies can split and the fastener can “mush” the core.

Two rules keep you out of trouble: seal it if there’s any chance of moisture, and don’t rely on it for strength. If you need a stronger interior alternative with a similar thin-panel purpose, compare with sande plywood, which often feels stiffer and more consistent in tight joinery.

Practical Notes From Real-World Use

The biggest surprise with luan is how often flat-on-the-rack becomes wavy after a day in a different space. I’ve had stacks that looked perfect at pickup, then developed a gentle twist overnight because one face absorbed shop humidity faster; storing sheets flat with weight on top fixed most of it, but the worst offenders never fully came back.

Another issue is finish telegraphing: seams, staple crowns, and even small debris under a sheet can show through vinyl or glossy paint once sunlight hits at a low angle. The workaround that actually holds up is treating prep like flooring prep—vacuum, skim-fill low spots, feather seams, then re-check by dragging a straightedge and listening for that scratchy “tick” that signals a ridge.

Cut quality causes pain too. A beginner will often blame the plywood, but the real culprit is a dull blade and no backer support, which turns the exit edge into a furry mess that drinks paint. I get cleaner results by using a fine-tooth blade, cutting with the good face down on a circular saw (good face up on a table saw), and scoring the surface when the edge will be visible.

Moisture is the non-negotiable risk. If luan gets wet, edges can swell and leave a “puffy” line you can feel with your fingertips even after it dries; once that happens, you’re often better replacing the panel than trying to sand it flat. If you need a panel meant for wet environments, swap to a purpose-built sheet like marine plywood and follow the material, adhesive, and fastening rules that come with it; FSRI’s luan panel listing is also useful if you’re checking material identifiers for compliance or documentation.

FAQs

What Is Luan Plywood Used For?

Luan plywood is a lightweight, economical sheet material used primarily for interior finishes and light-duty projects.

It’s commonly used for wall paneling, cabinet backs, drawer bottoms, decorative veneers, and craft work where high structural strength is not required. It cuts, paints, and glues easily but must be sealed and kept dry for longevity.

Is Luan Plywood The Same As Lauan Or Philippine Mahogany?

Luan (often spelled lauan) refers to lightweight tropical plywood and is not strictly the same as Philippine mahogany.

Philippine mahogany is a trade name that historically covered several Shorea species, while modern luan products vary by species and grade. Check the species, grade, and glue type rather than relying only on the trade name.

How Strong Is 1/4-Inch Luan Plywood?

Quarter-inch luan plywood is thin and intended for non-structural uses, offering low load-bearing capacity and noticeable flex under weight.

It works well as backing, cabinet backs, or decorative panels but requires solid framing or support when used horizontally. For projects needing strength or screw-holding, choose thicker plywood or engineered panels like Baltic birch.

Can Luan Plywood Be Used As Flooring Underlayment?

Luan plywood can be used as a temporary or light-duty flooring underlayment but is generally not recommended for modern permanent floors.

It will support some floor coverings if fully supported and sealed, but it can cup or delaminate with moisture and heavy traffic. Use exterior-grade plywood, OSB, or cement board for long-term durability and code compliance.

What’s The Difference Between Luan Plywood And Baltic Birch Plywood?

The main differences are species, construction, and strength: luan is thin, lightweight tropical plywood, while Baltic birch is a multi-ply, high-strength birch plywood built for durability.

Baltic birch has more plies, uniform face veneers, superior screw-holding, and dimensional stability, making it preferred for cabinets and furniture. Luan is cheaper and suited for low-stress interior finishes and veneers.