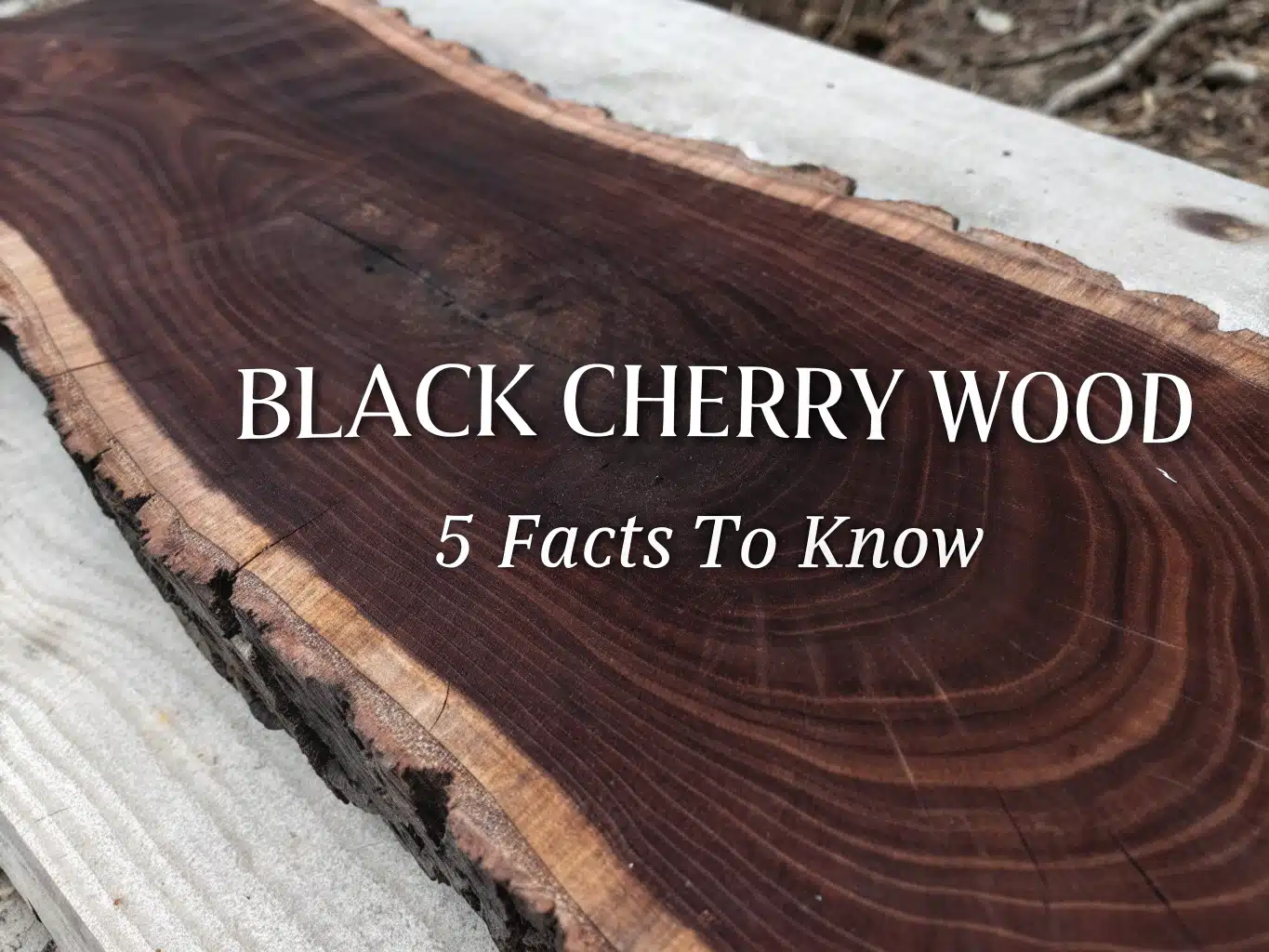

Black Cherry Wood: 5 Facts Every Woodworker Should Know

Have you seen a board shift from light pink-brown to deep russet with light and use? That is black cherry wood. It cuts clean. It sands fast. It takes a rich polish. Makers prize the fine, close grain. In this short read, you get five facts that matter, plus a simple check of Brazilian cherry and wood brazilian cherry so you can pick the right stock for your next build.

Table of Contents

I use black cherry wood when I need graceful color, dependable workability, and a finish that glows without much fuss. Its fine grain, warm patina, and steady supply across North America make it a smart pick for furniture, cabinetry, and crafted details where both beauty and practicality matter.

Physical and aesthetic characteristics of black cherry wood

Species and origin

Black cherry wood comes from Prunus serotina, often called American cherry or wild cherry. It’s native to North America and long valued by furniture makers for its stable growth, steady supply, and consistent color. The species yields a trunk that’s straight enough for clean lumber, with sapwood and heartwood that give distinct, attractive contrasts in boards and veneer.

Most lumberyards list black cherry under names like “American cherry,” “PA cherry,” or simply “cherry,” but the botanical tag tells you you’re looking at the right material. For a thorough species profile that covers color, texture, and typical properties, I like the reference at Rare Woods USA. It confirms the traits I see at the bench every day: fine texture, reliable machining, and a look that gets richer over time.

Color and grain

Freshly milled black cherry starts tan to light brown with a soft pink cast, while the sapwood shows as pale yellow. With exposure to light and air, the heartwood settles into a reddish-brown to russet tone that reads warm without looking heavy. On a table or cabinet door, that color pairs easily with brass, matte black hardware, or quiet oil finishes.

The grain is typically fine and close, which makes cherry feel smooth even before sanding to higher grits. While straight-grained boards dominate the racks, you’ll also see wavy or “curly” figure in some logs. Curly cherry can look dramatic under a clear coat, especially on drawer fronts or panels where light rakes across the surface. I orient those boards to catch the light and tighten my hand-plane setup to reduce tearout in the more active areas.

Sapwood gets a bad rap in cherry because its lighter tone breaks up the uniform look people expect. I use sapwood as a design feature: bookmatch panels to create symmetry, or set sapwood edges together to frame a darker center. With balanced layout, the contrast reads intentional and gives a custom feel to everyday pieces.

Ages to a deeper russet patina

Cherry is famous for its patina. Sunlight and oxygen slowly deepen the color, so a new project can shift from light brown to rich russet across the first year. I speed that process with a safe “sun tan”: a few hours of indirect daylight after final surfacing, rotating the parts for even exposure, then a clear topcoat to lock in the glow.

Because the look is so loved, other species often get stained to mimic cherry. You’ll see “cherry finish” on maple, birch, or poplar in budget lines. The surface color may be close, but the fine texture and depth aren’t quite the same. If a client wants the real warmth and chatoyance, I spec American black cherry and finish it with a clear or lightly tinted topcoat that lets the grain speak.

Black cherry hardwood specs

These numbers put black cherry in a sweet spot for indoor furniture: firm enough for daily use, yet easy on tools and sandpaper. If you’re picking between species for a desk or cabinet, these specs help set expectations for wear, feel, and handling.

| Property | Black Cherry Wood |

|---|---|

| Botanical name | Prunus serotina |

| Common names | Black cherry, American cherry, wild cherry |

| Janka hardness | 950 lbf |

| Average dry weight | ~560 kg/m³ |

| Texture | Fine, close-grained |

| Typical grain | Straight to gently wavy; curly figure appears in select logs |

| Color (heartwood) | Reddish-brown to russet; deepens with age |

| Color (sapwood) | Pale yellow to light cream |

I also watch for growth-ring spacing when picking boards for a project. Tighter rings yield uniform texture that planes and sands more predictably, while wider rings can add character on large panels. Both work beautifully; I just match them to the piece and the finish schedule.

Workability and finishing advantages

Easy to machine

Cherry machines cleanly with sharp knives and light cuts, which saves time on sanding and leads to a glass-smooth surface. It’s forgiving on the jointer, friendly on the router table, and kind to hand tools if you read the grain. I keep plane irons and scrapers very sharp and take thin passes; tearout stays low, and the burnished surface pops under oil or shellac.

Gluing is uneventful with modern PVA, epoxy, or hot hide glue on well-prepped surfaces. Cherry’s fine texture gives a large bonding area, so clamps come off with confidence. For sanding, I start at 150 or 180 grit after planing, move to 220, and stop there for most clear finishes. Over-sanding can make stain blotchier, so I keep to a light touch and consistent pressure.

Polishing and topcoating treat cherry kindly. Wipe-on varnish, oil/varnish blends, lacquer, and waterborne clears all yield a deep luster if the surface is flat. For a hand-rubbed glow, I wipe one thin oil coat, de-nib with grey pads, then lay down two clear coats for depth without obscuring the grain. For a quick shop finish, shellac seals beautifully and can be buffed to a mellow sheen.

For background on why woodworkers prize cherry’s workability and appearance, the summary from Purdue Arboretum echoes what I see on projects that leave the shop: stable boards, fine texture, and a classic look that suits many styles.

Substitutes for mahogany in fine furniture and cabinetry

I often spec black cherry where clients ask for a mahogany vibe but want domestic sourcing and easier finishing. Cherry’s color sits in the same family, and its tight grain delivers a similar elegance under clear coats. It pairs well with traditional joinery, carved details, and period hardware, yet also shines in clean, modern lines with minimalist pulls or push latches.

For doors and frames, cherry’s stability helps mortise-and-tenon joints stay tight across seasons. On drawer fronts, the soft glow ties into both light and dark interiors. If a piece calls for contrast, I’ll use quartersawn white oak or maple accents; cherry’s warm tone keeps the whole composition inviting.

Stains and topcoats that enhance black cherry wood

Cherry can blotch with pigment stains. I avoid headaches by using dye-based colorants, gel stains, or a dewaxed shellac sealer before pigment. If I want to amplify the natural red-brown, I wipe on a dye in a light russet tone, seal, then use a clear topcoat for a deep glow. For a classic look, oil/varnish blends warm the color, and waterborne clears preserve a lighter shade with less ambering over time.

Here are two reliable stain options in a black-cherry colorway that apply well on samples and small accent parts.

Varathane Fast Dry Wood Stain, Black Cherry, Quart

- Rich Black Cherry color enhances grain

- Fast-drying formula speeds projects

- Easy wipe-on application and control

- Ideal for furniture, doors, and trim

- Topcoat compatible after proper dry time

Varathane Oil-Based Wood Stain, Black Cherry, 1/2 Pint

- Deep, even color penetration

- Wipes on and blends easily

- Enhances natural wood character

- Ideal for interior furniture and cabinetry

- Ready for clear topcoats after drying

I always test color steps on offcuts from the actual project boards. That little practice removes guesswork and helps me tune sheen, tone, and clarity for the final look.

Tip I rely on: “Seal the first pigment coat with a thin barrier.” A quick pass of dewaxed shellac or a waterborne sanding sealer tames blotch and sets you up for an even, repeatable finish.

For a visual walkthrough on coloring and finishing cherry, the video below provides a helpful overview you can apply on panels, frames, and accents to reach a consistent, rich tone.

If you’re curious how cherry compares to other species for household builds, this guide to types of wood for furniture lays out strengths, looks, and maintenance so you can pick with confidence.

Durability, longevity, and maintenance

Stable and warp-resistant when properly kiln-dried

Well-dried black cherry stays put. I buy from mills that monitor schedules closely and target a uniform final moisture content for furniture. With consistent drying, cherry’s movement stays modest across seasons, which keeps panels flat and joinery lines tight. I still allow for wood motion with the right hardware, but parts remain steady if the material starts out right.

I also sticker and acclimate boards in the shop air for a few days before milling. First passes are light to release internal stress. Then I give parts a short rest after jointing and planing to final thickness, which helps the fiber settle before cutting joinery. That small pause pays off in stable assemblies and smooth glue-ups.

For general performance notes—stability, ease of finishing, and where cherry shines—the writeup at Rare Woods USA lines up with long-term results I’ve seen on cabinet doors and tabletops that live through winters and summers without fuss.

Moderate decay resistance

Black cherry offers moderate decay resistance in dry, indoor settings. I’ve used it in kitchens, living rooms, bedrooms, and offices with no trouble, and I’ve seen decades-old cabinets hold their joints, edges, and sheen. Outdoors, even under a porch roof, cherry weathers too quickly for my taste unless it’s a protected accent with diligent upkeep.

For service areas—drawer sides, cabinet interiors, trim behind doors—I sometimes switch to matching cherry plywood to save weight and cost. The veneers blend well with solid edging, and the core resists seasonal movement. The match is good enough that most people will never notice the transition.

Routine care

Cherry’s patina improves with gentle care. Dust with a soft cloth, use mild soap and water on sticky spots, and dry right away. I avoid harsh cleaners and silicone sprays that can cloud future touch-ups. If a sheen dulls after years of use, I scuff with a non-woven pad and refresh with a compatible topcoat for a clean renewal.

- Keep pieces out of direct, intense sun for the first month to let color deepen evenly.

- Use coasters and trivets; cherry handles heat from plates fine, but hot pans can print finishes.

- Wipe spills quickly, especially wine, coffee, or dye-heavy liquids.

- For scratches, try a wax stick or tinted touch-up marker; spot-sand only if needed.

- Refresh worn tops with a light scuff and one or two thin coats of the original finish to restore luster.

Cherry is sometimes used in cutting boards, but I prefer tighter-pored maple for heavy chopping. For food-prep projects, this guide to the best wood for cutting boards covers safe choices and maintenance so your board stays sanitary and stable.

Growth, sustainability, and forest ecology

Fast-growing hardwood

Prunus serotina grows quickly for a hardwood, which helps keep supplies steady and prices rational. Stands on good sites reach useful sizes in relatively short rotations compared with many temperate hardwoods. That growth habit supports a healthy market for black cherry lumber used in furniture, paneling, and millwork.

Strong sustainability

Black cherry carries strong sustainability credentials. According to Impactful Ninja, U.S. forests replace about one cubic meter of black cherry every 6.12 seconds, and it’s not listed as threatened or endangered. That turnover reflects abundant managed stands and a long history of domestic supply that supports both big mills and small shops.

I also like that consistent domestic sourcing keeps transport emissions lower than imports, and mills have dialed-in drying schedules for repeatable quality. Between the renewal rate and stable forestry, cherry checks the boxes for projects where clients care about sourcing and footprint.

Lower carbon footprint

Impact assessments point to a lower cradle-to-gate carbon footprint for kiln-dried black cherry compared with many mainstream hardwoods. The same analysis pegs cherry’s figure at roughly 301 kg CO₂-eq per cubic meter, which stacks up well against maple, ash, and white oak. Finished furniture then acts as a long-lived carbon store, keeping that carbon out of the atmosphere for decades.

Ecological role

In the forest, black cherry supports wildlife with fruit that feeds birds and small mammals. Young growth fills gaps after disturbance, and well-managed stands contribute to mixed hardwood diversity. I choose FSC- or similarly certified stock when possible to back up these benefits with credible oversight.

Historical context

Cherry surged in popularity as furniture makers looked for a domestic stand-in for imported mahogany. As secondary-growth forests matured through the 20th century, cherry became a key lumber species for casework and architectural trim. Its steady supply and familiar handling kept it on shop cut lists even as styles shifted from traditional to modern lines.

Uses, black cherry lumber options, and comparison with Brazilian cherry

High-demand applications

I reach for black cherry wood on projects where a warm tone and clean finish matter: kitchen cabinets, bookcases, built-ins, hutches, sideboards, and bedroom sets. It’s also a favorite for architectural trim, stair parts, and paneled rooms because it cuts clean profiles and holds crisp edges. Thin veneers bookmatch nicely on door panels and tabletop fields, while solid edging keeps corners durable.

You’ll also see cherry in specialty items—turned bowls, handles, toys, boxes, and stringed instruments—because it’s pleasant on the lathe and finishes without drama. For a deeper look at how foresters and woodworkers categorize uses, the USFS FEIS profile lists common products and roles alongside ecological notes. That mix of utility and beauty explains why black cherry lumber remains a go-to in small and large shops.

Why do craftsmen choose black cherry wood?

The reasons are straightforward. Cherry looks elegant without stain, sands fast, glues predictably, and takes both modern and traditional finishes. It holds routed details cleanly, accepts hand-cut joinery, and requires less corrective sanding than many hardwoods. On built-ins, doors hang true and panels sit flat with simple allowance for wood movement.

Material yield tends to be strong because boards come in friendly widths and lengths with minimal defects. With careful layout, I can optimize figure on panels, keep straight grain on rails and stiles, and save offcuts for drawer parts and small accents. That efficiency trims waste and cost across a project.

If you want a broader context before buying, this short primer on cherry wood summarizes the main traits, grades, and frequent uses so you can sort through options quickly.

Choosing black cherry lumber and craft stock

For furniture, I prefer FAS and select-grade boards for wide, clear panels, mixing in #1 Common for shorter parts and rails. I check color match under the same light I’ll use during finishing, and I sticker rough-sawn boards in the shop for a day before milling. Straight-grained stock goes to frames; the curly and wavy boards become drawer fronts, panels, and table fields.

Turners, carvers, and small-project makers can save time by starting with pre-cut blanks sized for lathes and benchtop tools. Below are ready-to-use options I’ve found handy for handles, bowls, inlay, and trim where uniform sizing speeds layout and finish work.

Barrington Cherry Turning Blanks, 2 x 2 x 6 (4-Pack)

- Square blanks ready for the lathe

- Straight-grained cherry for smooth cuts

- Consistent sizing for clean glue-ups

- Ideal for handles, knobs, and small spindles

- Sands and finishes to a warm, rich tone

Exotic Wood Zone Black Cherry Bowl Blanks, 6 x 6 x 2 (2-Pack)

- Kiln-dried stability reduces movement

- Unfinished blanks ready for custom shaping

- Sustainably sourced hardwood

- Great for decorative and functional bowls

- Accepts sanding and finish for a fine sheen

Black Cherry Thin Boards, 1/8 x 2 x 16 (3-Pack)

- Ideal for inlay, models, and edging

- Stable hardwood that cuts cleanly

- Smooth surfaces for reliable glue-ups

- Uniform sizing saves prep time

- Stains and finishes to a rich tone

Barrington Cherry Boards, 3/4 x 2 x 12 (4-Pack)

- Uniform dimensions for precise joins

- Smooth machining for clean edges

- Great for trim, craft, and small builds

- Stable hardwood with classic cherry look

- Finishes beautifully for lasting results

For buyers stepping into exotics, I often get asked about Brazilian cherry. If you’re weighing that species for flooring or casework, this quick look at Brazilian cherry outlines traits and project fit so you can pick the right material for the job.

Black cherry vs Brazilian cherry

Brazilian cherry (jatoba) sits in a much harder class than black cherry, which is why it shows up so often in flooring. That extra hardness resists dents yet brings tougher machining and heavier boards. Black cherry is gentler on blades and finishes with fewer steps, which suits furniture, built-ins, and millwork where close tolerances and touchable surfaces matter.

Color-wise, jatoba leans orange-red to deep red-brown and can darken significantly under UV. Black cherry starts light and shifts to a russet tone that stays warm and calm in most rooms. For a cohesive interior, I often choose black cherry for cabinets and trim, then use neutral floors; for a bold, high-traffic floor, Brazilian cherry makes sense if the design calls for that intensity.

On sustainability, black cherry’s domestic supply and strong replacement rate are easy wins for many projects. Jatoba depends on imports and can carry longer shipping routes and more complex sourcing. If a client wants a deep red floor with minimal denting, I’ll discuss jatoba’s pros and tradeoffs; if the brief calls for warm furniture with graceful aging, I point to black cherry wood for the finish quality and ease of working.

For anyone comparing both species from a design angle, this short guide format helps: think use-case first, then dial in species. Floors that see heavy traffic favor jatoba; furniture and interior details that benefit from smooth tooling, crisp joinery, and a rich patina favor black cherry. If you’re still choosing, skim both overviews, look at samples under real room light, and run a small test finish before you buy.

FAQs

What Are The Uses Of Black Cherry Wood In Furniture Making?

Black cherry is prized for fine furniture and cabinetry, including dining and coffee tables, chairs and rockers, desks, dressers, bed frames, built-ins, and case goods. Its straight, closed grain machines, glues, and finishes beautifully, making it ideal for mouldings, trim, paneling, and veneer. It also turns and carves well and steam-bends for curved parts like arms and backs, while its warm color deepens to a rich patina over time.

How Durable Is Black Cherry Wood Compared To Other Hardwoods?

Cherry is a moderately hard hardwood at about 950 on the Janka scale, softer than hard maple, white oak, and hickory but similar to walnut. It resists warping and moves predictably with humidity, holds joinery and fasteners well, and, with normal indoor use, lasts for decades. Expect it to dent and scratch a bit more easily than the hardest species, but it finishes and repairs cleanly.

Is Black Cherry Wood Good For Outdoor Use?

Cherry is not recommended for outdoor use because its natural decay resistance is low and UV and moisture break down the surface quickly. If you must use it outside, keep it under cover, elevate it off the ground, and apply a high-quality exterior finish with UV inhibitors, renewing the finish at least annually. For true outdoor durability, consider teak, ipe, or white oak instead.

What Are The Distinguishing Features Of Black Cherry Wood?

Heartwood ranges from pinkish to reddish brown and darkens noticeably with light exposure, creating a classic warm patina. The wood has a fine, uniform texture with a straight, closed grain, occasional curl or figure, and small gum streaks or pitch pockets. It machines smoothly, has a faint sweet aroma when worked, and finishes to a silky luster with excellent clarity.

How Do You Care For And Maintain Black Cherry Wood Furniture?

Dust regularly with a soft microfiber cloth and clean with a slightly damp cloth followed by a dry wipe. Use coasters, trivets, and felt pads, avoid harsh cleaners and silicone polishes, and keep humidity around 35 to 55 percent. Protect from direct sun or rotate pieces to patina evenly; refresh oil or wax finishes as needed and spot-repair light scratches with a wax stick or touch-up polish.