Luan Wood: 5 Key Facts for Your Next Project

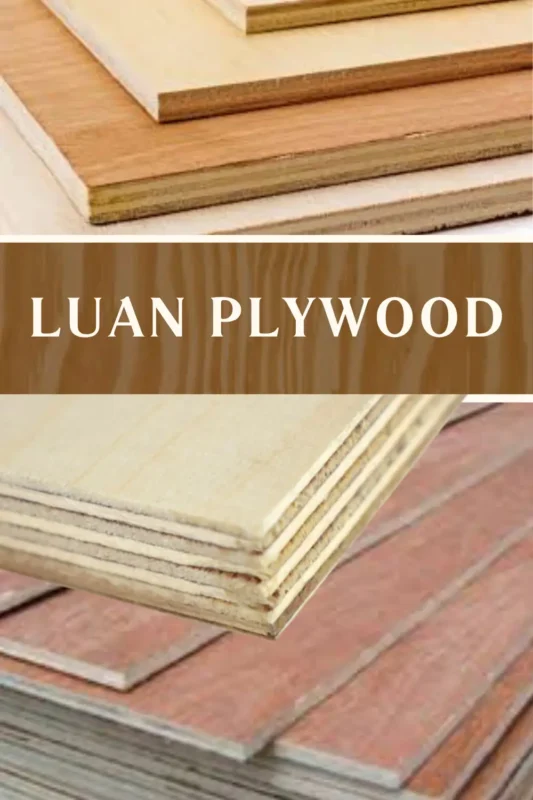

Ever wondered what luan wood really is? It is a thin, lightweight plywood sold as sheets and panels. You often see it used as underlayment, door cores, and backing in many indoor projects. This short guide covers the main types, sizes, common uses, and key limits so you can decide if luan is the right choice for your build.

Table of Contents

Luan wood is a lightweight, budget-friendly plywood made from tropical hardwoods that’s popular for underlayment, paneling, cabinetry, and crafts. This guide explains what is luan wood, how it’s made, common sizes, best uses, pros and cons, and smart buying tips.

What Is Luan Wood?

Definition and Origins

Luan wood (often “Lauan plywood” or Philippine mahogany) refers to engineered sheets made from Shorea species native to Southeast Asia; it’s a plywood, not a single tree species What Is Luan Wood?. For a deeper primer, see our guide to luan plywood and how it fits within interior-grade panels.

Main Varieties and Species

Shorea logs span several meranti groups, giving luan wood panels different colors and densities. Red meranti tends to be denser and more stable, while lighter meranti species yield paler, lighter sheets suitable for luan wood panels and craft work.

Construction and Manufacturing Process

Manufacturers rotary-cut veneers, then cross-laminate and press them with adhesives, giving luan its dimensional stability and resistance to splitting. Interior grades use moisture-resistant but interior-rated glue, while exterior or underlayment grades may use more water-resistant resins and tighter core standards.

Watch this quick overview to see how thin veneers become stable plywood that’s easy to cut and finish for interiors.

Physical Properties and Appearance

Texture and Grain Characteristics

Luan has a coarse texture with medium to large pores and sometimes interlocked grain, similar to mahogany at a fraction of the cost Mahogany/Lauan overview. For a smoother look, sand to 180–220 grit before stain or paint.

Color Variations

Tones range from pale straw to reddish-brown depending on species and veneer placement, so select sheets in person when color matching is critical. A light dye or toner can help even out face veneer differences across a room.

Weight and Density

Luan is relatively lightweight, often about half the mass of similar hardwood plywood, which helps with overhead or large-area installs. If weight is a key constraint, compare panel masses using our plywood weight guide before purchase.

Luan Wood Sheets: Sizes and Specifications

Standard Dimensions and Thicknesses

Most luan wood sheets are sold as 4×8 ft panels in 1/8–1/4 in thicknesses, with underlayment often in the middle of that range Luan flooring overview. See common panel sizes in our plywood dimensions explainer before you plan cuts.

| Thickness | Common uses | Approx. weight per 4×8 |

|---|---|---|

| 1/8 in (≈3 mm) | Crafts, wall paneling accents, drawer bottoms | ≈ 10–12 lb |

| 5/32 in (≈4 mm) | Flooring underlayment, closet backs, ceiling panels | ≈ 14–16 lb |

| 1/4 in (≈6 mm) | Cabinet backs, interior doors skins, utility sheathing | ≈ 20–25 lb |

Panel weight varies by species and glue; confirm actual mass against job load limits and handling needs.

Panel Types and Grades

Look for interior, exterior, underlayment, or utility grades, each with different glue lines, void allowances, and face quality. For clarity on letters and faces, review common plywood grades so your sheet matches the finish level you expect.

5 Key Applications for Your Next Project

Flooring Underlayment

Luan underlayment provides a flat, uniform surface for vinyl and similar finishes, with easy scoring and stapling to subfloors. Keep seams tight, leave slight expansion gaps at edges, and fill fastener heads for a smooth finish floor.

Interior Doors and Cabinetry

Thin luan skins work well on hollow-core doors and cabinet backs thanks to their light weight and stable faces. For a cleaner result, use a fine-tooth blade, back the cut to limit tear-out, and finish exposed edges with edge banding.

- Use 80→150→220 grit sanding for smooth faces before primer.

- Choose underlayment or better face grade for visible panels.

- Apply a stain-blocking primer if using paint finishes.

Wall Paneling and Ceilings

The light mass makes luan wood paneling quick to install on ceilings and accent walls with brad nails or construction adhesive. Paint, stain, or clear coat can give a “mahogany-like” look for tight budgets.

Furniture Backing Components

Use luan for cabinet backs, drawer bottoms, and closet systems where you want stiffness without bulk, then match the visible faces with trim. If you need small project panels, you can drop in a ready-made option at checkout for convenience.

General Construction Uses

Builders use luan wood panels for templates, millwork patterns, utility shelving skins, and as a sacrificial surface for shop jigs. For heavier-duty faces, consider stronger options like sande plywood in the same thickness.

Advantages of Choosing Luan Wood

Cost-Effectiveness

Luan provides a mahogany-like appearance at a fraction of the price, which helps stretch remodeling budgets. It’s widely available, so you can source multiple sheets with consistent faces for room-scale work.

Versatility and Workability

Panels cut, glue, and finish easily, making them helpful for DIY and pro crews alike. You can score with a knife for breaks, or use a fine-tooth blade for clean edges.

Structural Stability

Cross-laminated veneers reduce movement across humidity swings compared with solid wood boards. That stability keeps door skins flat and cabinetry backs square after installation.

Lightweight Installation

The low density means easier lifting, quicker overhead work, and fewer fatigue issues on large jobs. Confirm expected panel mass using our quick plywood weight reference before ordering a stack.

Important Considerations and Limitations

Moisture Resistance Factors

Standard luan isn’t highly water resistant, so avoid wet areas unless you choose exterior or underlayment grades with higher-quality glue lines and faces Luan plywood guide. Seal edges and penetrations to reduce swelling and face checking in humid rooms.

Finishing Requirements

Because the texture is coarse, plan on progressive sanding and a good primer or sealer, especially with paint finishes. If you want a smoother face out of the box, compare luan to sande plywood before you commit.

Tool and Hardware Compatibility

Some species can be silica-bearing, which dulls edges faster; keep spare blades handy. Pre-drill for screws near edges and use washers or finish nails with glue to limit splits.

- Cut with 60–80T fine plywood blades for cleaner edges.

- Use backer boards to reduce tear-out on crosscuts.

- Choose narrow-crown staples or 18ga brads for underlayment.

- Seal cut edges before high-humidity installs.

Grade Selection Guidelines

Pick a grade that matches visibility and moisture risk: underlayment for floors, better face grades for wall panels, and exterior-rated for damp zones. For quick decoding of letters and faces, skim our plywood grades chart before buying.

Alternative Wood Options for Craft Projects

If luan wood sheets aren’t ideal for small models or laser work, try these thin wood packs for consistent results.

20-Pack Basswood Craft Sheets

- Smooth, lightweight basswood ideal for painting and staining

- Thin 2mm sheets cut easily with craft knives, laser, and hobby tools

- Consistent thickness for ornaments, models, and small assemblies

- Accepts paint, glue, and woodburning for versatile finishing

- Pack of 20 gives material for multiple projects and practice

LINSHRY 5-Pack Basswood Sheets 1/16

- Large 12×8 in sheets suited for architectural models and classroom projects

- Smooth, uniform surface for painting, engraving, and decals

- Easy to cut, sand, and shape for fine detail work

- Lightweight, low-tension wood that resists warping

- Five sheets provide variety for practice and small builds

6-Pack Baltic Birch Plywood 3mm

- Durable multi-ply birch with a stable, flat surface for precision work

- B/BB grade offers a smooth face ready for finishing or staining

- Stronger and stiffer than single-ply woods for structural projects

- Ideal for laser cutting, CNC, scroll saw, and painting

- Six sheets give plenty of material for furniture, models, and prototypes

For larger craft panels or classroom sets, this batch gives more area and value per pack.

12-Pack Balsa Wood Sheets

- Ultra-lightweight balsa perfect for model airplanes and architectural mockups

- Soft grain sands and shapes quickly for custom parts and detailing

- Natural, unfinished surface accepts glue and paint easily

- Thin 1/16 inch thickness is ideal for delicate work and layering

- Twelve sheets provide ample material for hobby and school projects

30-Pack Basswood Sheets 12×12 in

- Large 12×12 sheets give room for bigger panels and multiple cutouts

- Thin 1.5mm thickness balances flexibility and dimensional stability

- Smooth, unfinished surface accepts paint, stain, ink, and varnish

- Cuts cleanly with laser, CNC, and hand tools for precise shapes

- Bulk 30-pack suits classrooms, studios, and repeat projects

Woodpeckers Baltic Birch 3mm Pack

- High-strength Baltic birch construction for sturdy, warp-resistant panels

- B/BB grade veneers provide a clean, sandable face for finishing

- Consistent 3mm thickness works well with lasers and CNC routers

- Holds fasteners and edges without splitting for reliable joins

- Six large sheets are great for cabinetry, signage, and detailed projects

Sustainability and Sourcing Considerations

Environmental Impact

Luan draws from tropical hardwoods across Southeast Asia, so purchasing choices can affect forest health and regeneration timelines. Learn how meranti, okoume, and similar species are marketed and graded from Anderson Plywood before you pick a source.

Responsible Purchasing Guidelines

Choose vendors that provide legality documents and certifications like FSC or PEFC, and avoid vague species labeling. When possible, match your spec to verified luan wood panels with clear face grades and thickness tolerances using our overview of ply board types.

FAQs

What Is Luan Wood Used For?

Luan is a lightweight hardwood plywood commonly used for interior applications like paneling, door skins, cabinet backs, drawer bottoms, underlayment, and decorative veneers where a smooth surface and low cost are priorities.

Is Luan Wood Suitable For Outdoor Projects?

No. Luan Is Not Recommended For Outdoor Use Because It Is Thin And Not Moisture-Resistant; It Tends To Warp, Delaminate, And Deteriorate When Exposed To Weather. If You Must Use It Outdoors, Seal All Surfaces And Keep It Protected From Direct Moisture, But Exterior Plywood Or Pressure-Treated Lumber Is A Better Choice.

How Does Luan Wood Compare To Plywood?

Luan Is A Type Of Lightweight Plywood With A Smooth Veneer Surface That’s Ideal For Finish Work, But It Is Generally Less Strong And Less Moisture-Resistant Than Structural Plywood Varieties. Standard Construction Plywood (Like CDX Or Marine Plywood) Offers Greater Durability And Load-Bearing Capacity.

Can You Stain Or Paint Luan Wood?

Yes. Luan Can Be Painted Or Stained, But Because The Veneer Can Be Thin And Uneven, Painting With A Primer Gives The Most Consistent Results. If You Stain, Test First And Use A Pre-Stain Conditioner To Reduce Blotching, Then Seal With A Clear Finish.

Where Can I Buy Luan Wood Sheets?

Luan Sheets Are Readily Available At Home Improvement Stores, Local Lumberyards, Specialty Plywood Dealers, And Online Retailers. Look For Listings Under “Luan,” “Lauan,” Or “Luan Plywood,” And Check Available Thicknesses And Grades Before Buying.