The Ultimate Guide to Sapele Wood: Characteristics, Uses, and Care Tips

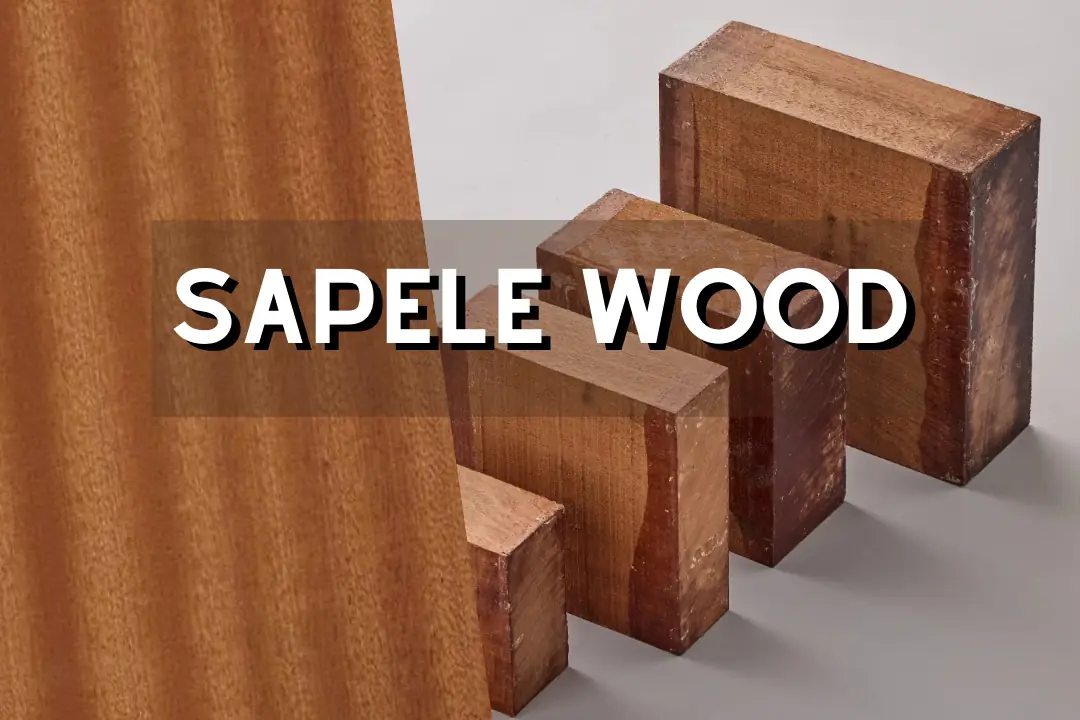

Sapele wood is an African tropical hardwood (Entandrophragma cylindricum) used as a mahogany-like material for furniture, doors, flooring, and instruments. It’s known for ribbon-striped grain, solid strength, and good stability, but it can tear out during planing and it can stain around iron or steel fasteners.

Table of Contents

If you’re asking what is sapele wood in practical terms: it’s a mid-to-high density hardwood that finishes to a deep glow, holds screws well, and behaves predictably after acclimation—yet it demands sharp tools and smart milling to avoid fuzzy grain and chipped edges.

What Is Sapele Wood?

Species and origin

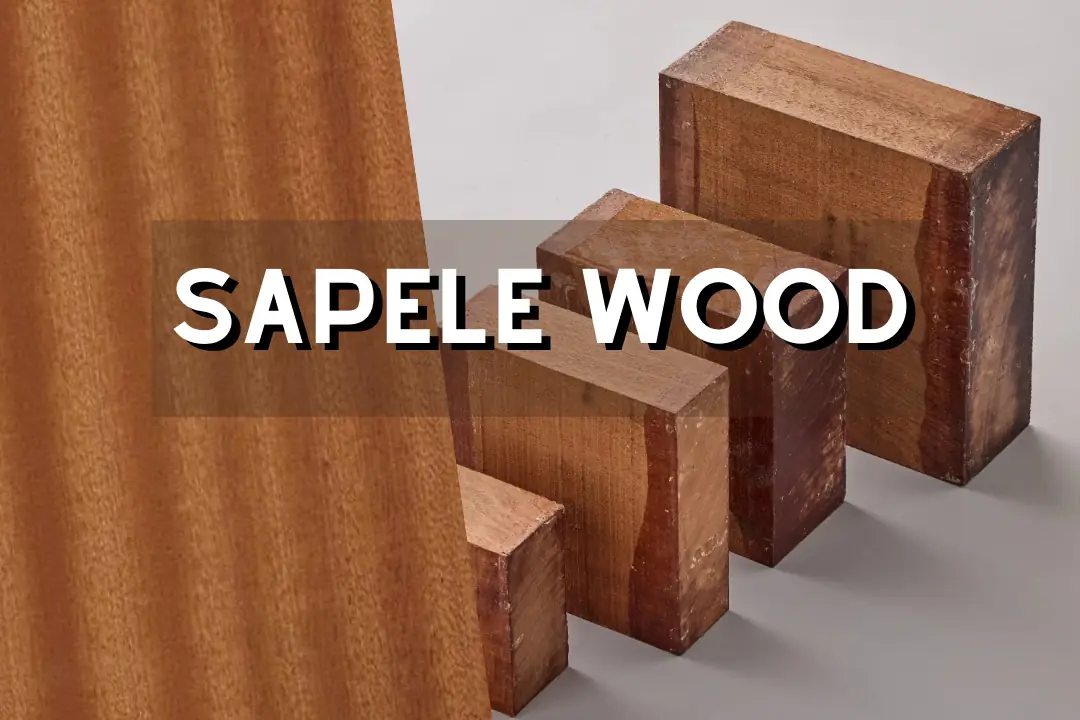

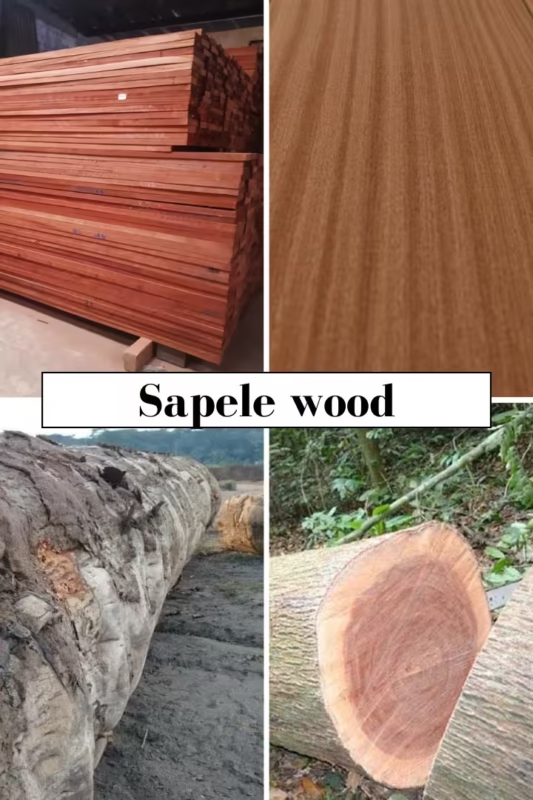

Sapele lumber comes from Entandrophragma cylindricum, a large African hardwood in the Meliaceae family (often grouped near “mahoganies” in the trade). In the shop, boards often arrive with a slightly spicy, cedar-like scent when freshly cut, and the dust feels fine and dry—easy to over-breathe if you skip extraction and a respirator.

Most stock on the market traces back to West and Central Africa, where trees grow tall, straight, and wide enough for long clear boards and veneer. If you want more context on related African species for look and performance, I cross-check sapele against African mahogany anytime a client asks for a “mahogany vibe” without the same supply constraints.

Names and look

You’ll see it sold as sapele, sapelli, or “sapele mahogany.” The base color runs from golden-brown to reddish-brown, and freshly sanded faces can look almost peachy under bright shop lights until finish hits it.

On quarter-sawn faces, stripe figure can look like alternating light and dark ribbons that “flip” as you walk past it. That chatoyance is real—under raking light it can feel like the board has depth, almost like the grain sits under glass once you build a film finish.

Sapele vs mahogany

Sapele gets compared to mahogany because the color family overlaps, it finishes beautifully, and it machines cleanly when grain is straight. The biggest day-to-day difference I notice: sapele’s interlocked grain shows more dramatic stripe on quartered stock, but it’s also more likely to tear out if you plane it like plain-sawn mahogany.

If you’re deciding between species, start with how the part will be cut: for show faces and door stiles, quartered sapele brings that ribbon look; for carved details, mahogany often behaves more predictably. For deeper comparison reading on your site, link out once to mahogany wood to see how grain structure changes the machining “feel.”

Sapele Wood Technical Specifications

Density and hardness

Sapele lands in the 640–750 kg/m³ density range, so it feels heavier than many domestic hardwoods when you lift a rough 8/4 board off a rack. In hardness terms, the commonly cited Janka number is 1,410 lbf, which means chair legs and door thresholds hold up well, but you’ll still see dents if grit gets trapped under something heavy and dragged.

Hardness context helps when clients pick finishes: a hard wood with a soft finish still scratches. I often pair sapele with tougher topcoats for floors and tables, and I sanity-check numbers against Wood Database: Sapele when I’m quoting wear expectations or matching it to another species.

Strength numbers

For structural feel, sapele has high stiffness and bends less than you’d expect for a “mahogany-like” wood. Published values often cited include MOR around 15,300 psi and MOE about 1.82 million psi, which shows up in real builds as shelves that feel more “solid” at the same thickness.

| Property | Typical figure used in shops |

|---|---|

| Density | 640–750 kg/m³ |

| Janka hardness | ~1,410 lbf |

| Bending strength (MOR) | ~15,300 psi |

| Modulus of elasticity (MOE) | ~1.82 million psi |

| Tangential shrinkage | ~7.2% |

| Radial shrinkage | ~5.2% |

Beginner mistake: treating these numbers like guarantees. Real boards vary by cut and growing conditions, so I still do a quick test mill—one light pass on the jointer and planer—before committing to final dimensions.

Dimensional stability

Stability is one of sapele’s best traits when it’s dried well. Low-to-moderate shrinkage means panels stay flatter and doors move less across seasons, but you can still get “wind” in wide boards if you surface them and immediately rip them into parts without letting stresses relax.

Workaround that saves projects: rough mill parts 1–2 mm heavy, sticker them overnight (or a few days for thick stock), then final plane. That pause often prevents a door stile from turning into a banana right after glue-up.

Durability and Weather Resistance

Rot and decay

Sapele heartwood rates from moderately durable to durable for decay, so it can handle occasional wetting better than many indoor-only woods. That said, I don’t treat it like teak: ground contact, trapped water, and end grain that stays wet will still shorten its life fast.

If you need real outdoor longevity, the real “secret” isn’t fancy finish—it’s water management: drip edges, venting, and sealing end grain. One good reference point for general durability notes is Duffield Timber’s sapele guide, but field performance still comes down to design details.

Insects and termites

Termites are a real edge case where sapele gets oversold. Some stock holds up fine indoors, yet sapwood is still more vulnerable, and in high-risk regions I treat sapele like “needs protection” rather than “naturally protected.”

Pro workaround: if the project goes into a known termite zone, I avoid sapwood entirely, borate-treat non-visible faces where appropriate, and pick stainless or coated fasteners to stop staining and reduce corrosion points that can attract moisture.

Exterior performance

Exterior doors and trim do well in sapele when you build and finish them like exterior work, not like indoor cabinetry. Under sun, the surface warms quickly to the touch, and unprotected color can shift—so if you want the “fresh milled” reddish tone, you’ll need UV-blocking finish and a maintenance plan.

Common mistake: sealing only the show face. I finish all sides of exterior parts as evenly as possible so moisture intake stays balanced, which cuts cupping and joint stress.

Grain, Texture, and Aesthetics

Interlocked grain

Interlocked grain means fibers change direction as the tree grows. In the shop, you’ll feel it as a planer that suddenly starts pulling little chips out “against the grain” even if the board looked consistent at first glance.

If you’re still learning grain reading, it helps to compare sapele’s shifting fiber to simpler species using your site’s wood grain pattern guide. Quick habit that prevents tear-out: I mark grain arrows on every part after the first milling pass, then I keep that orientation through joinery and final surfacing.

Ribbon stripe figure

Ribbon stripe shows strongest on quarter-sawn stock, where alternating bands catch light at different angles. For cabinets and doors, I’ll often “bookmatch” panels so the stripes mirror each other across the seam—done right, it looks intentional and high-end without any extra carving.

Trade-off: the most dramatic stripe often comes with more interlock, so you pay for beauty with harder milling. If the project has lots of cope-and-stick profiles, I pick boards with slightly calmer figure for the rails and stiles and save the wild stuff for flat panels.

Color and patina

Color shift is real with sapele. Fresh surfaces start brighter, then deepen into a richer brown-red over time, and the change speeds up in direct sun; you can even see “tan lines” if a rug or object sat in one place for months.

If you’re matching old and new parts, I’ll tint the finish slightly and blend with toner coats rather than trying to stain raw wood darker in one step. For color planning across species, your colors of wood resource helps set expectations before you commit to a whole-room install.

Workability: Machining, Joinery, and Finishing

Tear-out prevention

Tear-out is the #1 frustration with sapele, and it can happen fast on a jointer, planer, or even a handplane. If you’ve ever felt a board go from silky to crunchy under a plane in one stroke, that’s interlock switching direction.

- Use lighter cuts: thin passes beat “hogging off” material.

- Skew the cut on a jointer or handplane to lower effective cutting angle.

- Switch to a higher cutting angle or a sharp back-bevel on a handplane for nasty spots.

- For show faces, scrape or sand the last bit rather than chasing perfection with more planing.

- Mill stripey quartered faces with extra margin, then final-surface after joinery.

Beginner mistake: sanding tear-out away after the fact without checking thickness. Tear-out can be deeper than it looks, and chasing it can make a tabletop uneven; I’ll stop, re-evaluate grain direction, then decide if scraping or localized patching makes more sense.

Tool wear and routing

Tool wear is moderate: sapele isn’t the worst exotic for edges, but it will dull cutters faster than many domestics. On a router table, you’ll hear the tone change when a bit starts going dull—more whine and heat—and the cut edge can turn slightly fuzzy.

Workaround: climb-cut risky grain areas in very light passes (with solid workholding), then finish with a standard pass to clean up. That approach reduces blowout at the exit where sapele loves to chip, especially around end grain profiles.

Iron staining risk

Iron staining shows up as gray-blue marks when iron reacts with wood extractives, and sapele can do this around wet steel wool, carbon steel tools left on damp boards, or unprotected fasteners. The worst cases I’ve seen happened when someone used regular steel screws on an exterior door and water got into the pilot holes.

Workaround you’ll actually use: pick stainless or coated fasteners, predrill clean holes, and keep steel wool away from open grain unless you’re 100% sure it’s non-ferrous. If you do get stains, oxalic acid often lifts them, but you must neutralize and re-sand lightly before finish.

Glue and fasteners

Glue-up is usually trouble-free if surfaces are fresh and flat. Sapele takes PVA well for interior work, and its screw holding feels strong—drivers “bite” and threads seat firmly—yet you still need pilot holes because the density can split narrow parts near edges.

Pro tip for clean joints: wipe oily or dusty surfaces, and don’t over-clamp. Too much pressure can starve a joint, and with dense hardwood that failure can show up later as a hairline seam under finish.

Finishes and polish

Finishing is where sapele earns its reputation. A simple oil will make the ribbon figure pop, and film finishes can build a deep, glassy look; when you rub out the final coat, the surface can feel like warm stone—slick, cool, and dense under your palm.

Common mistake: staining to “look like mahogany” without testing. Sapele can take stain unevenly on interlocked patches, so I test on offcuts from the same board, then use a washcoat or gel stain if I need more control.

Common Uses for Sapele Lumber

Furniture and decor

Furniture is a natural fit because sapele balances strength, stability, and looks in one material. I like it for table aprons, legs, and casework frames where you want crisp edges that still survive bumps from daily life.

If you’re choosing wood for a whole build and want alternatives with different weight or color, your wood for furniture guide helps you map species to real use, not just appearance.

Flooring and cabinetry

Flooring in sapele holds up well under foot traffic, and it looks richer after finish and time. For cabinetry, quartered sapele gives you that clean stripe on long runs of doors, but you’ll want consistent board selection so one bank of cabinets doesn’t look wildly different from the next.

Cabinet-shop tip: keep rails and stiles from the same flitch when you can. Grain and color shifts are easier to manage before parts are cut, not after a whole kitchen is assembled.

Doors and windows

Doors are one of my favorite uses for sapele because it stays stable and resists everyday dents. For exterior units, build with proper joinery, seal end grain, and pick weatherproof finishes; the wood can handle the job, but the details decide whether it lasts.

Common mistake: skipping drip caps and water sheds because the wood “is durable.” Durable wood still fails when water sits in the same joints year after year.

Marine and outdoor

Marine trim and outdoor pieces can work in sapele with the right build choices, but I treat it as “needs maintenance.” Salt air and sun will punish any coating, and once a finish cracks, moisture can get underneath and lift it in sheets.

Workaround: use penetrating systems where re-coating is easy, avoid trapped seams, and design parts so you can sand and refresh without disassembling a whole build.

Instruments and inlays

Instruments and decorative work benefit from sapele’s luster and stable behavior. It’s common in guitar bodies, neck laminations, and veneers, where ribbon figure reads as “premium” under clear finish without needing dye tricks.

If you like strong, dark species for accents, compare it with wenge wood for contrast; wenge is darker and splinter-prone, while sapele is smoother under sanding but trickier under a plane.

Pros, Cons, and Sustainability

Key advantages

Strength is the headline benefit: sapele holds fasteners well, resists dents, and works for parts that can’t feel flimsy. The look is another big win—ribbon stripe and natural luster can read “high-end” without stains or heavy color work.

Stability is also a day-to-day advantage: once acclimated, it stays put better than many woods with similar visual impact.

Key limitations

Machining can bite beginners. Interlocked grain tear-out, edge chipping during routing, and blotchy stain attempts are the usual problems, and you can waste expensive stock fast if you don’t change tactics early.

Outdoor risk is the other limitation: sapele can work outside, yet it’s not a “set and forget” wood. Skipping end-grain sealing, using plain steel fasteners, or leaving a horizontal surface where water ponds will shorten service life.

Responsible sourcing

Sourcing matters because sapele is a tropical hardwood with a slower growth pattern than many plantation species. I look for clear chain-of-custody paperwork and prefer suppliers that can document responsible forestry; a decent starting point for broader species notes is Ligna Wood Design’s sapele overview.

Practical buying tip: ask for consistent cut (rift/quarter if you want stripe), moisture content near your shop’s conditions, and permission to reject boards with excessive sapwood if your project is at insect risk.

Choosing Sapele Lumber and Specialty Products

Boards for building

Board choice decides how easy your project feels. For cabinetry and furniture, I pick straighter grain for rails/stiles and reserve heavy stripe for panels; for trim, I prioritize long, calm grain that won’t chip at profiles.

These sapele board sizes cover common small builds and shop fixtures:

Sapele Hardwood Boards 3/4 inch x 4 inch x 18 inch (2-pack)

- Kiln dried for stability and reduced warping

- consistent 3/4 inch thickness for accurate milling and joinery

- deep reddish brown color with attractive interlocked grain

- sands, stains, and finishes evenly for a smooth result

- great for furniture, trim, and small woodworking projects

Sapele Boards 3/4 inch x 6 inch x 24 inch (2-pack)

- Generous 6 inch width ideal for shelving and broader panels

- uniform 3/4 inch thickness for consistent joinery

- rich mahogany tones enhance finished pieces

- mills and planes smoothly with minimal tearout

- perfect for furniture, cabinetry, and larger DIY builds

Sapele Long Boards 3/4 inch x 4 inch x 24 inch (2-pack)

- Extra length suited for trim, moldings, and long runs

- stable kiln dried stock for reliable results

- appealing interlocked grain that takes stain well

- easy to cut, plane, and finish to match decor

- great choice for cabinetry, shelving, and crafts

Sapele Strips 3/4 inch x 2 inch x 12 inch (4-pack)

- Four uniform strips ideal for inlays, accents, and small projects

- consistent sizing simplifies glue ups and laminations

- smooth surface ready for sanding and finishing

- rich color adds visual warmth to craft pieces

- lightweight and easy to handle for detailed work

Turning, knife, and veneer

Specialty blanks save time because you skip the worst milling steps where tear-out happens. For turning, sapele cuts cleanly with sharp tools and sands to a high sheen; for veneer, the stripe figure can look unreal once it’s laid up and cleared.

These packs fit common turning, knife-handle, and veneer needs:

Sapele Turning Blanks 4-Pack 1-1/2 inch x 6 inch

- Kiln dried blanks that hold shape well on the lathe

- straight grain for predictable turning and clean cuts

- ideal size for pens, bottle stoppers, and small bowls

- easy to sand and finish to a high sheen

- sustainably sourced for eco friendly projects

Sapele Knife Scales Precut

- Precut scales sized for knife handles to simplify build time

- dense hardwood offers excellent edge and impact resistance

- beautiful grain patterns add unique character to each handle

- machines and sands cleanly for a comfortable ergonomic fit

- takes oils and finishes for a lasting, food safe surface

Extra Wide Sapele Veneer Sheets 22 x 98 inch

- Extra wide sheets ideal for speaker baffles, tabletops, and large panels

- straight grain offers a clean, uniform appearance

- unfinished surface ready for glue down and finishing

- flexible and thin for bending and laminating

- perfect for furniture restoration and guitar work

Cutting boards and food use

Food contact projects like cutting boards can work with sapele if you build them right and finish with a food-safe system after full cure. The big beginner mistake is leaving pores unsealed around end grain or rushing glue-up; liquids can wick in and leave dark lines if squeeze-out wasn’t cleaned well.

For strip-style boards, long consistent pieces make glue-ups easier and flatter:

Practical Notes From Real-World Use

What surprised me the first time I built a set of sapele cabinet doors was how quickly a “perfect” planed surface can turn into a torn surface two inches later. The fix wasn’t new machines—it was changing the process: lighter passes, sharp knives, and accepting that a card scraper can beat a planer for final show-face prep.

Another gotcha is color matching across a room. If you mix flat-sawn and quarter-sawn pieces, the chatoyance shifts so much that stain won’t unify it; you’ll see it most at night when warm bulbs hit the wood at an angle and the stripe flashes brighter than the surrounding panels.

Fastener staining is the real-world failure I see most on exterior projects. A single missed pilot hole that cracks a stile can invite water, then iron reacts and leaves a shadow you can’t sand out without changing the profile—so I default to stainless, predrill, and seal holes before I drive screws on outdoor installs.

Dust control matters more than people expect. Sapele dust is fine and hangs in the air; you can feel it dry your throat after a long sanding session, so I run extraction, wear a respirator, and vacuum before finishing to avoid nibs and gritty film.

FAQs

What Is Sapele Wood And Where Does It Come From?

Sapele is a West and Central African hardwood harvested from Entandrophragma species and commonly sold as sapele lumber.

It grows in countries like Ghana, Cameroon, and Ivory Coast and is prized for its rich, reddish-brown color and distinctive ribbonlike grain. Furniture makers, cabinet shops, and instrument builders use it for veneers, doors, and guitars because it balances stability and attractive figure.

Is Sapele Wood The Same As Mahogany?

Sapele is not the same as true mahogany, though it is often marketed as “African mahogany” because it belongs to the same family (Meliaceae).

They are different species with distinct grain patterns, color tones, and mechanical properties—sapele tends to have a more interlocked grain and darker reddish hues. For many projects you can substitute one for the other, but finishing, machining, and tonal characteristics will differ.

How Hard Is Sapele Wood Compared To Oak?

Sapele is a relatively hard hardwood with a Janka hardness around 1,400 lbf, making it similar to or slightly harder than common oaks.

Compared to red oak it is generally harder and denser, while it is often comparable to white oak. Expect similar wear resistance for flooring or furniture, but machining behavior and grain can make it feel different in use.

Is Sapele Wood Good For Outdoor Use Without A Finish?

No—sapele should not be left outdoors untreated for long periods because it will weather, gray, and eventually degrade.

Although it has moderate natural durability, prolonged exposure to moisture and UV requires a protective finish or regular maintenance to preserve color and prevent checking. Use exterior-grade sealers or marine varnish, or choose more durable tropical species or treated lumber for long-term outdoor projects.

Why Does Sapele Lumber Tear Out When Planing Or Routing?

Sapele tears out when planing or routing because it often has interlocked, reversing grain that lifts fibers instead of cutting cleanly.

Avoid tear-out by using very sharp cutters or carbide blades, taking light passes, cutting with the grain where possible, and using a sacrificial backing board. Scoring the cut line or using higher spindle speeds with lower feed rates can also produce smoother edges.

Thank you for a complete presentation of beautiful sapele wood. The wood is so stunning I almost dont want to cut it. Thanks barbra