Timber Wood vs Lumber vs Wood: What’s the Difference

Ever wondered what timber wood really means compared to lumber or plain wood? The words are used in different places and by different trades. This short guide will make the names clear. You will learn how each term links to processing, look, and common uses.

Table of Contents

Confused by the terms timber wood, lumber, and wood? This guide gives clear, side‑by‑side meanings, regional notes, and project tips so you pick the right material every time.

Understanding Timber Wood vs Lumber vs Wood

Basic Definitions and Terminology

Timber wood usually refers to raw logs or cut pieces that are not fully finished. Lumber, on the other hand, means milled boards that are cut to standard sizes and ready to use. Both come from the same wood source. For a deeper explainer, see What is the difference between timber, lumber and wood?.

In daily speech, many people mix these terms, yet trades use them with precision to avoid costly mistakes. For general building context, you can review core construction wood basics.

Regional Usage Variations

In the US and Canada, people say lumber for processed boards and timber for logs or standing trees. In the UK, Europe, Australia, and New Zealand, timber can mean both raw logs and finished structural material.

Industry-Specific Meanings

Foresters use timber from trees and logs. Sawmills call their rough-sawn output timber or rough lumber. Retailers sell dimensional lumber by size and grade. Builders rely on standard lumber dimensions so parts fit with minimal planing.

Global Regional Differences in Wood Terminology

North American Usage

North American yards stock “lumber” for framing, trim, and cabinets; “timber” usually refers to large sections or raw logs. For an accessible overview, see What is the difference between timber and lumber.

UK and European Standards

In the UK and much of Europe, “timber” covers both rough and planed structural sections sold by strength class and moisture state. Many projects also combine structural timber with laminated wood for longer spans.

Australian and New Zealand Terms

Australia and New Zealand use “timber” for framing and joinery products across hardwood and softwood species. Merchants list sizes in millimetres and often sell visual grades for appearance work.

Key Differences: Timber vs Lumber Comparison

Think of timber wood as earlier in the process and lumber as ready-to-install boards, though regional language can flip that label. A quick matrix helps you choose fast, with more detail at Timber vs Lumber: What’s the Difference.

| Feature | Timber | Lumber |

|---|---|---|

| Stage | Logs or sawn, often unplaned | Milled, cut to standard sizes |

| Common Uses | Beams, frames, heavy structures | Cabinetry, trim, flooring |

| Look | May have rough faces or bark | Clean, smooth, barkless |

| Regional Term | UK/EU/AU common | US/CA dominant |

| Precision | Lower by default | Higher, ready to fit |

Processing Stages

Rough timber gets sawn, sorted, dried, and then planed to produce straight, stable stock. Many shops request kiln-dried wood to reduce movement after installation.

Typical Applications

Builders pick big timber for posts, beams, and trusses where section size carries heavy loads. Finish carpenters prefer lumber for tight joints, fine trim, and furniture parts that need stable dimensions.

Appearance and Characteristics

Timber can show waney edges and saw marks until planed, while lumber arrives smooth and ready for fast assembly. Species choice drives color, grain, and hardness across both categories.

Types and Classifications of Timber Wood

Hardwood Timber Varieties

Popular hardwood timber includes oak, walnut, and mahogany for strength, rich color, and clean finishes. For project picks, browse practical wood for furniture ideas by use and price.

Hardwoods suit visible parts that take stain well and resist wear in tables, stairs, and high‑traffic areas. They’re pricier but offer long service life with proper sealing.

Softwood Timber Options

Pine, spruce, and fir give affordable, light, and workable stock for framing and interior trim. Many sheet goods pair with softwood cores; check practical plywood dimensions for cabinet and subfloor layouts.

Softwoods take screws easily and mill fast, which cuts install time. They can dent more readily, so plan protective finishes in busy rooms.

Dimensional vs Rough Classifications

Dimensional timber or lumber is milled to standard sizes, while rough stock comes oversized for custom milling. Many shops buy rough to control final thickness, grain match, and yield; a quick primer is available at What is the difference between lumber and timber?.

- Use dimensional for speed and predictable fit.

- Pick rough when you need extra thickness after flattening.

- Mill in stages to reduce warp and keep accuracy.

Common Applications and Uses

Structural Construction Projects

Large timber sections work well for posts, beams, joists, and trusses that demand high capacity. Bridge decks, barns, and timber‑frame homes often specify big sections for stiffness and look.

Fine Woodworking and Furniture

Cabinetry, casework, and tables benefit from milled lumber for flatness and precise joinery. Boards with straight grain and stable moisture help doors stay flat and drawers slide cleanly.

DIY and Home Improvement

Home projects like shelving, accent walls, and workbenches thrive on easy‑to‑cut, stable stock. Pine and poplar keep costs low while stains and paints deliver the look you want.

- Use 2x lumber for studs, simple benches, and jigs.

- Choose hardwood offcuts for cutting boards and small boxes.

- Pick plywood cores for wide panels that resist cupping.

- Seal edges and faces to limit seasonal movement.

Choosing the Right Material for Your Project

Structural vs Precision Work

Pick timber wood for large spans and load paths; pick lumber for tight joinery and repeatable parts. For stability in fine work, start with dry stock like quality kiln-dried wood.

Regional Considerations

Write or shop using the local term: “lumber” in North America, “timber” in the UK, EU, and Oceania. For language clarity, see timber vs. lumber usage notes.

Cost and Availability Factors

Softwoods usually cost less and come in longer lengths, which helps on tight budgets. Hardwoods price higher but save rework on visible surfaces thanks to better wear and finish quality.

Timber Wood Repair and Maintenance Solutions

For small dents, cracks, and color fixes, these proven fillers help you match species and get a clean finish.

Walnut Wood Repair Filler

- Rich walnut tone for seamless color matching

- Smooth, easy-to-spread putty for quick repairs

- Sands cleanly for a flush finish

- Accepts stain and finish for natural look

- Durable, long-lasting repair in an 8oz jar

Red Oak Wood Repair Paste

- True red oak shade for tight color matches

- Easy application fills cracks and gouges smoothly

- Sands down to blend with surrounding wood

- Compatible with stains and sealers for finishing

- Hard-wearing formula for furniture and trim

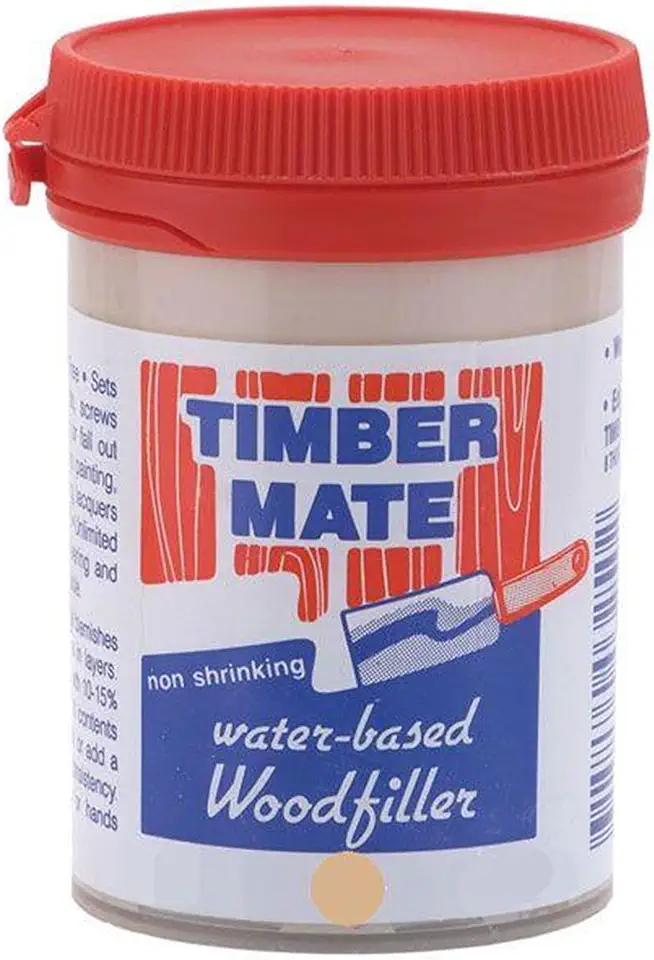

Natural Water-Based Wood Filler

- Low-odor, water-based formula for easy use

- Cleans up with water—no solvents needed

- Dries ready for sanding and finishing

- Blends well with natural wood tones

- Ideal for indoor furniture and trim repairs

Maple, Beech & Pine Wood Filler

- Color blend tailored for maple, beech, and pine repairs

- Smooth consistency for filling dents and holes

- Sands to a fine finish for seamless repair

- Stains and finishes to match surrounding wood

- Durable formula for long-term fixes

Mahogany Wood Repair Filler

- Deep mahogany shade for precise color matching

- Easy-to-shape paste for detailed repairs

- Sands smoothly for flush results

- Accepts stain and clear finishes for perfect blend

- Tough, lasting repair for furniture and trim

Color-Matching Solutions

Test a small patch under the same light to check color before you fill the entire area. Blend stains in thin layers until the patch matches the surrounding board.

Professional Grade Fillers

Pick a filler that sands clean, accepts stain, and bonds well to reduce future touch-ups. For big voids, pack in layers and re‑sand between coats to keep the repair flat.

Construction and Building Resources

Timber‑frame builders need clear joinery methods and span rules; this guide covers both with drawings and plans inside

Timber Frame Construction Guide

- Comprehensive look at post-and-beam building techniques

- Clear explanations of joinery and framing principles

- Includes practical design and construction tips

- Illustrated examples and plans for real projects

- Great resource for builders and DIY enthusiasts

Building Techniques and Methods

Use layout lines, story sticks, and reference faces to keep joints square and repeatable. Pre‑fit large members on the ground, then raise assemblies with proper bracing and safe lifting gear.

Measure twice, cut once, and stage every lift before anyone leaves the ground.

Carpentry proverb

Essential Reference Materials

Keep span tables, moisture meters, and species charts on hand so your choices match load, exposure, and finish goals. Pair those with shop notes for jigs, bit sizes, and blade settings to speed repeat work.

FAQs

What Are The Different Types Of Timber Wood Used In Construction?

Common Types Include Softwoods Like Pine, Spruce, And Fir For Framing; Hardwoods Such As Oak, Maple, And Mahogany For Flooring And Finishes; Engineered Products Like Plywood, OSB, Glulam, And LVL For Structural Applications; And Tropical Hardwoods For Outdoor Or Decorative Uses. Choice Depends On Strength, Durability, Appearance, And Cost.

How Do You Treat Timber Wood For Outdoor Use?

Treatments Include Pressure-Treating With Preservatives, Applying Water-Repellent Sealers, Stains Or Paints, And Using Natural Oils Or Borate Preservatives. Proper Kiln Drying Before Finishing And Installing With Good Detailing To Avoid Water Trapping Are Also Important. Reapply Finishes As Part Of Regular Maintenance.

What Is The Difference Between Hardwood And Softwood Timber?

Hardwoods Come From Broadleaf Trees And Tend To Be Denser And Harder, While Softwoods Come From Conifers And Are Usually Lighter And Grow Faster. Hardwoods Are Often Used For Flooring, Furniture, And High-Wear Areas, While Softwoods Are Common In Framing And General Construction. Species Properties Matter More Than The Label.

How Sustainable Is Timber Wood As A Building Material?

Timber Can Be Highly Sustainable When Sourced From Responsibly Managed Forests Because It Stores Carbon, Has Lower Embodied Energy Than Steel Or Concrete, And Is Renewable. Look For Certification (FSC, PEFC), Local Sourcing, And Reclaimed Or Engineered Wood To Improve Sustainability. Unsustainable Logging And Long Transport Distances Reduce Benefits.

How Can You Prevent Timber Wood From Rotting Or Warping?

Prevent Rot And Warping By Keeping Wood Dry And Well-Ventilated, Using Species Or Treatments Suited For The Exposure, Applying Protective Finishes Or Pressure Treatment, Ensuring Good Design Details For Drainage And Airflow, Avoiding Ground Contact, And Performing Regular Inspections And Maintenance.