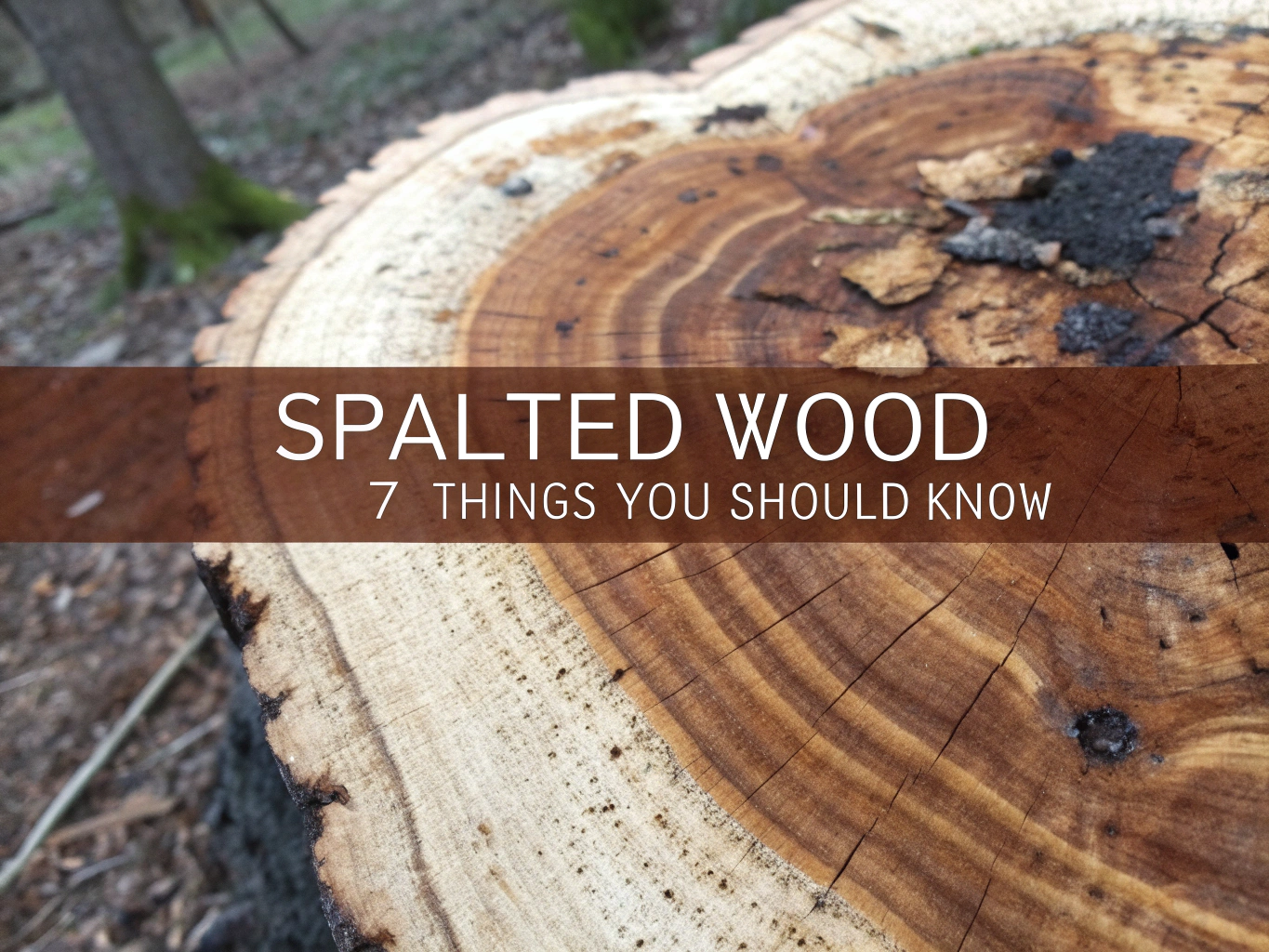

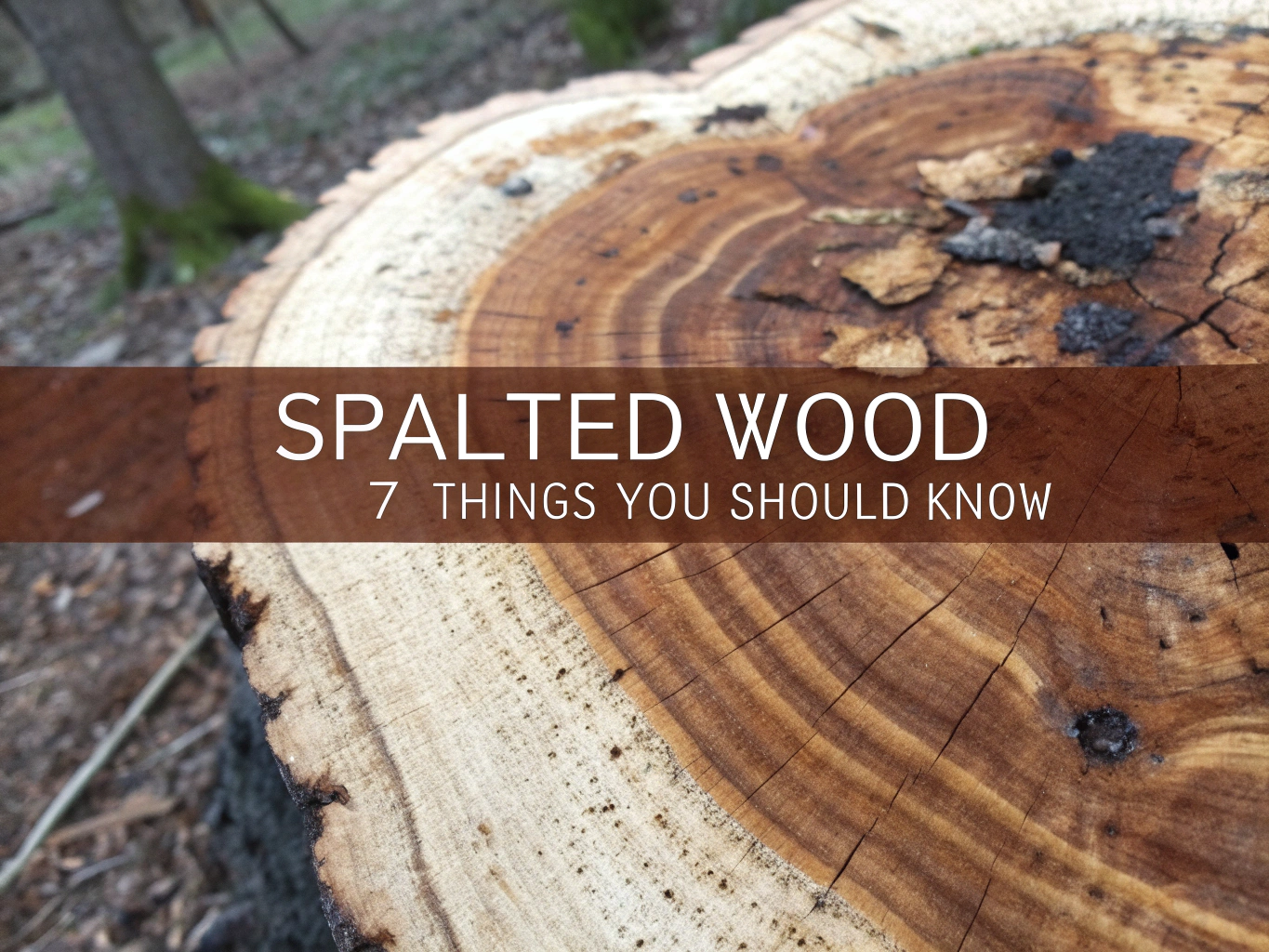

Spalted Wood: 7 Things You Should Know

Ever spotted a piece of wood that looks like abstract art and wondered why? That effect often comes from spalted wood. Wood spalting happens when fungi grow in the timber and leave dark zone lines, white rot streaks, and color stains. This post answers what is spalted wood, how the spalting process works, which spalted woods are popular (including spalting maple wood), and how to pick safe, stable pieces for your projects.

Table of Contents

Spalted wood looks exotic because fungi color the grain with dark lines, streaks, and patches. This guide explains what is spalted wood, how it forms, how to pick quality pieces, and how to use it safely.

What Is Spalted Wood?

Definition and Formation Process

Spalted wood is lumber marked by fungi that move through the fibers and leave dark “zone lines,” light streaks, and colored patches. The fungi feed on compounds in the wood and leave these visible signatures behind.

You’ll see spalting most often in dead or stressed logs where moisture, oxygen, and mild warmth are present, which are the same basic conditions fungi need to thrive. For a clear primer on what creates those lines and colors, see the Penn State article What is Spalted Wood.

Natural vs. Artificial Spalting

Natural spalting happens in forests and log piles, then millers harvest boards before decay goes too far. Artificial spalting uses controlled moisture, temperature, and inoculation to color wood more predictably.

How the Spalting Process Works

Fungal Competition and Nutrient Extraction

Different fungi compete inside the log and draw nutrients from cell walls, which creates zone lines where colonies meet. Pigments and bleaching happen as byproducts of that competition, giving wood its dramatic figure.

Commercial sellers cut and dry boards once the figure looks great but before the wood turns weak or crumbly, a timing window that protects both beauty and strength. For a quick overview with photos, see What Is Spalted Wood and What Makes It So Special?.

Environmental Conditions Required

Fungi need moisture, oxygen, and mild warmth; cool, damp seasons with airflow are ideal for coloring but risky for structure if left too long. Dense species take longer to show color, while paler sapwoods reveal contrast sooner.

Distinctive Visual Features of Spalted Wood

Zone Lines

Zone lines appear as thin, dark, often wavy borders where fungal colonies meet, and they add graphic contrast without always weakening sound wood. These lines can frame figure beautifully, much like how burl wood highlights swirling grain in a different way.

Zone lines, pigments, and bleaching often occur together, giving each board its own one-of-a-kind map of color and texture.

Vermont Wildwoods

White Rot Patterns

White rot fungi digest lignin and leave pale or bleached streaks, but they can soften fibers. Light bleaching with firm fibers is workable; deep bleaching with spongy spots signals structural risk.

Pigmentation Effects

Some fungi leave blue, red, brown, purple, or yellow tones that show best on pale sapwood. These colors can shift with finish choice, so test an offcut with your preferred finish before committing.

Best Wood Species for Spalting

Spalting Maple Wood

Maple is a favorite because its light sapwood makes dark lines and pigments pop clearly. Learn how makers use it in our guide to spalted maple wood, and compare base material traits in maple wood.

Species and figure matter for looks and handling, so woodworkers often compare spalted maple with ambrosia maple and birdseye maple. For species data and photos, see the Spalted Maple entry.

Other Popular Spalted Woods

Many species spalt well, though color and fiber strength vary with density and moisture. Pale, diffuse-porous hardwoods tend to show the most dramatic contrast.

- Beech, birch, and sycamore for fine lines and even tone

- Poplar and hackberry for quick color development

- Hickory for bold lines but firmer cutting feel

- Tropical options like tamarind and mango for vivid pigments

Physical Properties and Workability

Weight and Hardness Characteristics

Base species dictate weight and hardness, while spalting can reduce both slightly as fungi process cell walls. Plan for sharper cutters and gentle passes to keep tearout low.

| Example species | Typical dried weight | Janka hardness | Spalting impact |

|---|---|---|---|

| Maple (hard/soft) | ~38–44 lb/ft³ | ~700–1,450 lbf | Slight softening; lines highly visible |

| Birch / Beech | ~37–43 lb/ft³ | ~910–1,300 lbf | Good contrast; moderate softening |

| Poplar | ~22–31 lb/ft³ | ~300–540 lbf | Colors develop fast; can turn soft |

| Tamarind | ~50+ lb/ft³ | Higher density | Vivid pigments; cuts clean when stabilized |

Structural Integrity Considerations

Freshly spalted boards can be sound and stable if dried promptly, but long exposure can create punky zones. Use a fingernail or awl test to check fibers; soft, crumbly spots call for stabilization or rejection.

Safety and Quality Considerations

Identifying Sound vs. Punky Wood

Sound spalted wood feels firm under pressure and shows crisp machining, while punky areas dent easily and shed fibers. If dust smells musty and fibers fuzz, stop and evaluate before proceeding.

Wear a respirator and collect dust well, since fungal residue and fine particles can irritate lungs; kiln drying kills active growth but dust still deserves care. For a plain-language safety note, see Spalted wood — beautiful, but is it safe?.

Proper Drying and Stabilization

Dry stock to a target moisture level that matches your shop, then seal surfaces quickly with your finish of choice. For soft spots, use thin CA glue or vacuum resin to harden fibers before final machining.

Popular Uses and Applications

Woodworking Projects

Spalted maple slabs make striking tabletops, accent panels, and instrument caps because lines amplify figure. Turners love bowl and vessel blanks for flowing forms that showcase contrasting lines.

Knife makers, pen turners, and box makers often start with pre-sized blanks to save time and reduce waste. Compare figure styles with birdseye maple if you want subtler surface movement.

Decorative and Functional Items

For cutting boards, utensils, and serving ware, pick stock that’s fully sound and sealed to handle daily use. If your board includes softer sections, stabilize and finish well or reserve it for light duty service.

Below are curated blanks and references for bowls, pens, handles, and more, including stabilized options for cleaner machining and durable results.

Spalted Wood: A Guide to History & Art

- Comprehensive overview of spalted wood history and uses

- Clear explanations of the biological and chemical processes behind spalting

- Practical guidance on identifying and selecting spalting for projects

- Techniques for stabilizing and preserving spalted wood

- Inspiration and project ideas for woodworkers and artists

Stabilized Spalted Tamarind 5-Pack

- Stabilized and kiln-dried for immediate use

- Consistent dimensions for predictable turning and machining

- Bold, unique spalting patterns for eye-catching results

- Suitable for pens, handles, and small projects

- Low maintenance and easy to finish

Spalted Tamarind Knife Scales — Stylish Handles

- Striking spalting patterns for custom knife handles

- Ready-to-machine dimensions for accurate fitting

- Dense, stable wood that holds pins and adhesives well

- Smooths and polishes to a high sheen

- Adds a unique, high-end look to custom knives

Spalted Tamarind Lumber 3/4" x 2" x 24" — 5-Pack

- Five uniform boards ideal for cutting boards and projects

- Kiln-dried and stabilized for minimal warping

- Rich spalting adds decorative interest to finished pieces

- Easy to cut, glue, and machine to size

- Great value pack for multiple projects

Spalted Tamarind Bowl Blank 6 x 6 x 3"

- Perfect size for small to medium lathe bowls

- Dramatic spalting patterns for standout turnings

- Kiln-dried for stability on the lathe

- Accepts finishes evenly for a beautiful sheen

- Ready for sanding, turning, and decorative work

Spalted Tamarind Pepper Mill Blank 3" x 3" x 12"

- Sized for pepper mill projects and tall turnings

- Kiln-dried and stable for safe turning

- Bold, decorative spalting for a striking finish

- Solid square block that machines cleanly

- Compatible with a variety of finishes and hardware

Spalted Tamarind Pen Blanks 3/4" x 5" (5-Pack)

- Five matched pen blanks for consistent projects

- Stabilized and ready for turning

- Distinct spalting and grain for unique pens

- Easy to shape, sand, and polish to a high gloss

- Ideal size for most pen kits

Spalted Tamarind Bowl Blank 4" x 4" x 2"

- Ideal dimensions for small to medium bowl turnings

- Rich spalting offers dramatic visual interest

- Kiln-dried to reduce cracking and movement

- Easy to turn and finish smoothly

- Great for decorative and functional bowls

Spalted Tamarind Cutting Board Blocks 3/4" x 2" x 18" (5-Pack)

- Pack of five uniform boards for multiple projects

- Excellent for cutting boards, inlays, and knife scales

- Kiln-dried for stability and low moisture content

- Attractive spalting brings unique character to each board

- Easy to mill, glue, and finish

DIY Spalting and Advanced Learning

You can culture spalting at home by controlling moisture and air, using fungal starters, and pausing the process before decay spreads. Pick sapwood from species you know well—maples are predictable; browse types of maple trees if you’re choosing logs.

Work outdoors or in a ventilated space, label tubs with dates, and check fibers weekly so you stop at peak color and contrast. For a practical how-to guide with project tips, see below.

Spalting 101 — Guide to Coloring Wood

- Step-by-step methods for creating spalting with fungi

- Advice on species selection and wood preparation

- Safety tips and equipment recommendations for spalting projects

- Techniques to control colors and patterning

- Tips for finishing and preserving spalted wood

FAQs

What Is Spalted Wood And How Is It Formed?

Spalted wood is lumber that has been partially colonized by fungi, which creates distinctive dark zone lines, color stains, and marbled patterns. It forms when fungi invade dead or dying wood under the right combination of moisture, oxygen, and temperature; different fungal species produce different colors and textures, and the effect can occur naturally or be encouraged in controlled conditions.

How Can You Identify Spalted Wood?

You can identify spalted wood by its characteristic dark zone lines (thin black or brown lines), irregular color stains (such as pinks, blues, or grays), and areas of white rot that create soft, bleached-looking patches. Look for contrasting patterns when the surface is planed or sanded; if the wood has unusual, high-contrast streaks and lines that don’t match normal grain, it’s likely spalted.

Is Spalted Wood Dangerous?

Spalted wood itself is not inherently toxic, but the fungi that caused the spalting can produce spores and, in rare cases, mycotoxins. Working with spalted wood can release fine, moldy dust, so always use good dust extraction and a proper N95 or better respirator, eye protection, and gloves. Fully dried and sealed spalted pieces are generally safe for finished furniture when appropriate precautions are taken during milling and finishing.

How Do You Stabilize Spalted Wood For Furniture Making?

Stabilize spalted wood by first selecting pieces with sound structural areas and removing or trimming away overly punky sections. Dry the wood thoroughly, then consolidate soft or punky spots with penetrating stabilizers such as cyanoacrylate, low-viscosity epoxy, or commercial wood hardeners; vacuum or pressure impregnation helps for deeper penetration. Fill voids and cracks with epoxy or resin mixes, laminate or back the piece for added strength, and use strong joinery and finishes to lock the wood’s structure before using it in furniture.

Does Spalted Wood Require Special Care Or Maintenance?

Finished spalted wood needs similar care to other fine wood furniture, but it benefits from a few extra precautions: keep it dry and avoid prolonged exposure to high humidity, reapply protective finishes as needed, and avoid heavy impact on thin or heavily spalted areas. If the piece wasn’t fully stabilized when made, monitor for new softness or decay; properly sealed and finished spalted wood can last many years with routine care.