Wood Hardness Scale: What the Janka Numbers Really Mean

Did you know the hardest measured wood, Australian Buloke, scores 5,060 lbf on the Janka test? The wood hardness scale uses that test to show how well a species resists denting. This article lays out five key facts to help you pick wood for floors, furniture, or shop projects. Read on for clear comparisons and quick tips.

Table of Contents

The wood hardness scale explains how tough each species is against dents and wear in a clear, comparable way. Use this guide to pick the best hardwoods for 2025 based on the Janka rating and real-life needs.

What Is the Wood Hardness Scale

Definition and Measurement Method

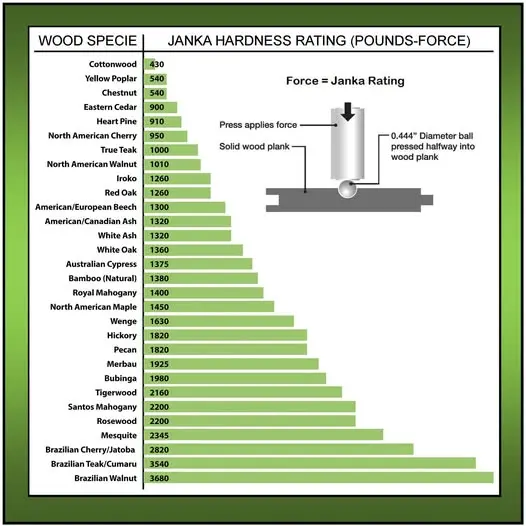

The Janka wood hardness scale is the standard scale for wood hardness used by flooring, furniture, and woodworking professionals. It reports the force needed to push a 0.444-inch steel ball halfway into a wood sample, expressed in pounds-force (lbf) or newtons (N) as a practical Janka rating reference Wood Database: Janka Hardness.

Janka hardness numbers give a simple, comparable measure of dent resistance across species.

Wood Database

Higher numbers mean tougher surfaces that resist dents and wear. Lower numbers point to easier cutting and shaping, though they tend to show marks sooner in daily use.

How the Janka Test Works

Test labs press the steel ball into a prepared sample until it reaches half-depth, then record the applied force. Standard conditions often include moisture near 12% to make results comparable across species Rejuvenation FD: Janka Hardness Scale.

Results vary by grain direction and sample defects, so look for averages across multiple boards. Treat Janka numbers as a practical guide, not an absolute promise of real-world performance.

Understanding Janka Rating Numbers

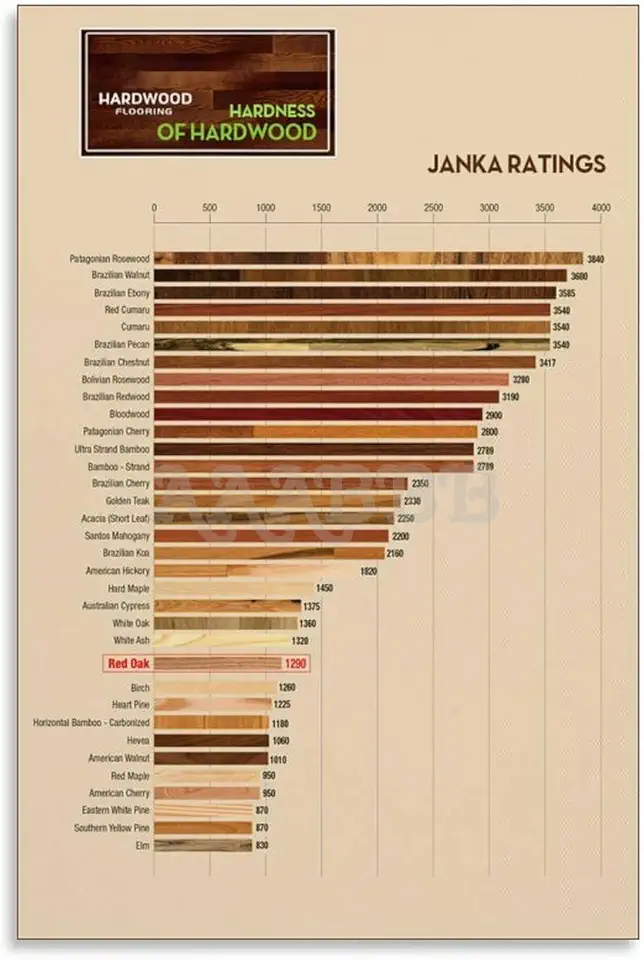

Red oak around 1,290 lbf sits near the midpoint of common hardwoods, so it’s a simple baseline for comparing species (red oak). Woods at or above 1,290 lbf handle daily traffic well, while softer options show marks sooner.

Ultra-hard exotics above ~2,500 lbf resist dents strongly but can be harder to machine and finish with standard tools. Softwoods and very low Janka hardwoods work easily yet suit light-duty or decorative projects.

1. Hardest Woods Dominate the Janka Scale

Australian Buloke Leads at 5,060 lbf

Australian Buloke tops the chart at about 5,060 lbf, far beyond common domestic species. It’s documented among the highest recorded values in published Janka lists Alan’s Factory Outlet Janka List.

Other Ultra-Hard Exotic Species

Other elite species include Baraúna (~4,800 lbf), Quebracho (~4,570 lbf), Guayacan (~4,500 lbf), and Gidgee (~4,270 lbf). Historic favorites like lignum vitae hover near 4,390 lbf with a renowned track record in heavy-duty uses.

Common Domestic Hardwood Ratings

Hickory (~1,820 lbf) is among the hardest North American options for floors and tool handles (hickory). Maple (~1,450 lbf) and white oak (~1,360 lbf) deliver a balanced mix of durability and workability (maple; white oak).

Red oak around 1,290 lbf still serves millions of homes for sturdy, affordable flooring. Its popularity makes it a practical benchmark for the wood hard scale (red oak).

2. Janka Ratings Guide Practical Applications

High-Traffic Areas (Above 1,290 lbf)

Hallways, kitchens, and living rooms benefit from woods above the 1,290 lbf mark. Retail floor guides point buyers to harder options for dent resistance in busy spaces Nielsen Bros Flooring: Hardness Guide.

Hickory, maple, white oak, and Brazilian cherry each handle abrasion from pets, toys, and dropped items. Choose species with a solid Janka rating and a durable finish for long-term service.

Moderate-Use Spaces (1,000-1,290 lbf)

Bedrooms and studies can use species around 1,000–1,290 lbf. These woods offer decent wear resistance and easier cutting, saving time on installation.

Low-Traffic Applications (Below 1,000 lbf)

Softer woods suit wall paneling, accent pieces, and areas with light foot traffic. Curious about poplar’s role in this range? See this primer: is poplar a hardwood.

3. Hardness Isn’t the Only Factor

Stability and Moisture Response

Dimensional stability affects gaps and cupping as seasons change, so check species movement as well as hardness. Flooring specialists stress that finish and humidity control matter for long-term results Superior Flooring: Janka & Stability.

Grain Pattern and Aesthetics

Grain and color shape the entire room, so compare straight, open, or swirling patterns with your design. White oak’s medullary rays, maple’s clean look, and hickory’s bold contrast each set a different visual tone.

Cost and Lifestyle Considerations

Budget, pets, and maintenance time all influence the right pick for your home. A tough finish can protect softer species, while harder woods can reduce repair frequency.

4. Popular Woods Compared on the Scale

White Oak Benchmark

White oak around 1,360 lbf stands as a dependable benchmark for strength, stability, and style. Learn more about its uses and look here: white oak.

Maple and Hickory Performance

Hard maple at ~1,450 lbf is common in sports floors and cabinets for its clean appearance. Hickory near 1,820 lbf resists heavy wear and impacts in high-traffic spaces (maple; hickory).

Exotic Options Like Brazilian Cherry

Brazilian cherry (Jatoba) around 2,350 lbf offers deep reddish tones and premium dent resistance for busy homes. Many buyers compare it to hickory and white oak using a simple Janka chart Wood Database: Janka Chart.

| Species | Janka (lbf) | Common Uses |

|---|---|---|

| White Oak | ~1,360 | Flooring, furniture, cabinetry |

| Red Oak | ~1,290 | Flooring, stairs, trim |

| Hard Maple | ~1,450 | Sports floors, cabinets, butcher blocks |

| Hickory | ~1,820 | High-traffic floors, tool handles |

| Brazilian Cherry (Jatoba) | ~2,350 | Premium floors, stairs |

| Strand Bamboo | ~1,380 | Eco-friendly flooring |

5. Reference Charts Simplify Wood Selection

Visual Comparison Tools

Wall charts turn the Janka hardness rating scale into a quick visual lookup for shops, classrooms, and home studios. The three posters below make species comparisons easy.

Janka Wood Hardness Chart — 12x18 Art Print

- Clear Janka hardness reference for quick material comparisons

- High-quality canvas print with vivid inks

- Compact 12x18 size fits workshops and home walls

- Stylish educational decor for living rooms or studios

- Easy to hang or frame for instant display

Janka Hardness & Density Chart — 8x12 Print

- Side-by-side Janka hardness and density ratings for quick reference

- Compact 8x12 size perfect for workbenches or small walls

- High-contrast layout for easy reading at a glance

- Decorative and informative for woodworkers and designers

- Unframed print ready for custom framing or mounting

Large Janka Wood Hardness Poster — 20x30 Print

- Oversized 20x30 chart makes hardness ratings easy to read from a distance

- Clear Janka gradations help select the right wood for projects

- High-quality print suitable for shops, studios, or classrooms

- Decorative and practical piece for woodworking enthusiasts

- Unframed format allows custom mounting or framing

Workshop and Educational Use

Post a chart above the bench so you can compare species during design, cutting, and finishing steps. Teachers also use these visuals to explain the Janka wood hardness scale during quick demos

Tips for Homeowners and Woodworkers

Choosing Based on Janka Ratings

Match the Janka number to the room’s traffic so the surface wears at a predictable rate. Use 1,290 lbf as a practical line: above for busy rooms, below for light-duty or accent areas.

- Kitchen, hall, entry: aim for 1,300–2,000 lbf for dent resistance and long life.

- Bedrooms, offices: 1,000–1,300 lbf balances durability and workability.

- Low-traffic or wall use: under 1,000 lbf is fine and easier to machine.

- Pets and kids: prefer harder woods or tougher finishes for fewer dents.

- Refinishing plan: select a species with adequate thickness for sanding.

Workability vs Durability Trade-offs

Harder woods last longer yet can dull blades and complicate joinery. Softer species cut faster and glue well, but they trade away dent resistance.

Using Reference Tools Effectively

Keep a printed Janka chart in the shop so decisions stay quick and consistent. Compare numbers for white oak, maple, hickory, and Brazilian cherry before you buy, and save links to reliable sources.

FAQs

What Is The Hardest Type Of Wood On The Janka Hardness Scale?

Australian Buloke Is Generally Recorded As The Hardest Wood On The Janka Scale — Often Around 5,060 Lbf — Though Results Can Vary By Sample And Source. Other Extremely Hard Woods Include Ipe And Quebracho. Keep In Mind That Very Hard Woods Can Be Tougher To Machine, Fasten, And Work With.

How Is Wood Hardness Measured And Why Is It Important?

The Janka Test Measures The Force Required To Embed A 0.444-Inch Steel Ball Halfway Into The Wood, Reported In Pounds-Force (Lbf) Or Newtons. It’s Important Because It Gives A Standardized Measure Of Resistance To Denting And Wear, Helping You Compare Species For Flooring, Furniture, And Tool Selection. However, It Doesn’t Reflect Toughness, Flexibility, Or Dimensional Stability.

Can The Janka Hardness Scale Help Me Choose Flooring?

Yes — The Janka Number Is A Useful Guideline For Flooring Choice: Higher Values Indicate Better Resistance To Dents And Heavy Traffic. As A Rough Rule, Species Above ~1500 Lbf Work Well In High-Traffic Areas, 1000–1500 Lbf Are Good For Typical Residential Use, And Below 1000 Lbf Suit Low-Traffic Or Decorative Areas. Also Consider Finish, Plank Thickness, Installation, And Humidity Control.

Are There Any Wood Species That Are Known For Being Particularly Soft?

Yes. Balsa Is By Far The Softest Commonly Measured Wood (Often Around 100–350 Lbf). Other Soft Species Include Eastern White Pine, Basswood, Poplar, And Some Cedars And Firs. Soft Woods Are Easier To Work And Lighter But Dent And Scratch More Readily, Making Them Less Suitable For High-Wear Flooring.

How Does Wood Hardness Impact Furniture Durability?

Hardness Influences A Piece’s Resistance To Dents, Scratches, And Edge Wear — Harder Woods Generally Hold Up Better For Tabletops, Legs, And Surfaces That See Heavy Use. That Said, Durability Also Depends On Design, Joinery, Finish, And Construction Quality; A Well-Built Piece From A Softer Wood Can Outperform Poorly Made Furniture From A Harder Species.