Hemlock Wood: Top 7 Uses You Should Know

Wondering if hemlock wood will work for your next project? This wood is strong, affordable, and easy to work with. It shows up in framing, paneling, saunas, furniture, and pallets. Below we explain seven top uses and how Eastern, Western, Canadian, and American types differ.

Table of Contents

Hemlock wood is a versatile softwood used for framing, paneling, saunas, and many practical projects. This guide explains types, properties, common uses, and how to pick the right hemlock for your build with clear actionable tips.

1. What Is Hemlock Wood?

Types of Hemlock Species

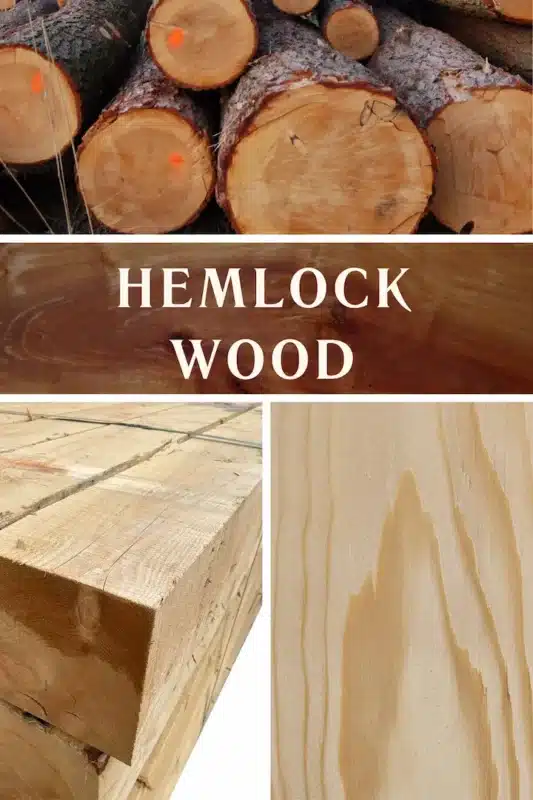

Hemlock lumber comes from the Tsuga genus, including Eastern Hemlock (Tsuga canadensis), Western Hemlock (Tsuga heterophylla), and Mountain Hemlock (Tsuga mertensiana). Sellers may list boards as Canadian hemlock or American hemlock, based on origin and supply.

Eastern Hemlock grows across eastern North America, while Western Hemlock thrives in the Pacific Northwest and coastal British Columbia. Mountain Hemlock appears in higher elevations and sees less harvesting due to access and terrain limits.

Key Characteristics and Properties

Color runs light reddish-brown with a generally straight grain and coarse texture, and the wood lacks pitch pockets or strong resin smell. It machines and glues well, takes stain evenly with pre-conditioning, and shows low natural decay resistance so exterior use needs treatment.

Workability stays friendly for hand and power tools, though the species can splinter on cross-grain cuts; a sharp blade and light passes help. For species-level details, see Eastern Hemlock data including machining notes and finishing tips, which apply broadly to Tsuga spp.

Sustainability and Availability

Supply is strong across North America, with most hemlock species listed as “least concern” and widely harvested for construction and millwork. Buyers can find kiln-dried boards, S4S trim, and framing lumber through big-box stores and regional lumberyards.

2. Construction and Framing Applications

Structural Components

Builders use hemlock for studs, joists, beams, rafters, and subflooring where appearance matters less than straight stock and stable fastening. It planes to uniform dimensions, nails cleanly, and keeps weight manageable for quick site work.

- Stud walls and interior partitions

- Roof rafters and ceiling joists

- Temporary beams, shoring, and bracing

- Subfloor panels, blocking, and sleepers

General Building Uses

General-use applications include utility shelving, shop tables, interior frames, and built-ins that get painted or stained. For load and grade basics, review this primer on construction wood to match species and grade to your project’s stress needs.

Keep cuts crisp with sharp blades and reduce tear-out with light passes; pre-drill near edges to limit splitting.

Shop-floor tip

Cost-Effectiveness Benefits

Pricing often undercuts premium softwoods while delivering straight, long stock in common dimensions. Compare span tables with Douglas fir wood for framing decisions, and buy by the unit for better job costs.

3. Interior Paneling and Trim Work

Wall Paneling Applications

Hemlock paneling offers a clean, low-odor interior surface with subtle grain for modern or rustic rooms. Use tongue-and-groove boards over furring, leave small gaps for movement, and keep fasteners aligned for tight, consistent lines.

Molding and Custom Trim

Trim carpenters like hemlock for casings, baseboards, and crown because it profiles well and sands quickly. Pre-prime or sand to 180–220 grit, then fill nail holes with color-matched putty for crisp, paint-ready edges.

Finishing and Staining Properties

Finish with a sanding sealer or pre-stain conditioner for even tone across earlywood and latewood. If you want a more aromatic interior species for contrast, compare with cedar wood before final color choice.

4. Sauna and Spa Construction

Heat and Humidity Resistance

Canadian hemlock performs well in saunas because it stays stable at high temperatures and doesn’t ooze pitch. Species notes in this hemlock species reference align with common sauna-grade selections used by kit makers and cabinet shops.

Sauna Accessories and Components

Benches, backrests, and headrests made from hemlock stay comfortable to the touch and resist sap bleed. Use hidden stainless fasteners, round over edges to 1/8–1/4 in., and leave vents for safe air circulation.

Here are popular hemlock sauna backrests that fit most benches and home units.

Hemlock Sauna Backrest (13 x 20.5 in)

- Ergonomic S-shaped support cradles the lower back

- Natural hemlock withstands high heat and humidity

- Smooth, non-toxic finish with no staining

- Lightweight yet sturdy for long-term use

- Easy to place on benches or mount on walls

S-Shaped Hemlock Sauna Backrest — Single Pack

- Contoured S-shape for improved posture and comfort

- 100% Canadian hemlock construction for sauna conditions

- All-natural finish—no stains or harsh chemicals

- Simple installation and repositioning as needed

- Durable design made for regular sauna use

Dynamic Hemlock Sauna Backrests — 2-Pack

- Two ergonomic backrests to improve comfort for multiple users

- Made from durable Canadian hemlock suited for high-heat environments

- Smooth, ready-to-use finish without staining or toxic treatments

- Easy placement on benches or quick mounting to walls

- Enhances posture and relaxation during sauna sessions

Canadian Hemlock Advantages

Benefits include mild aroma, consistent color, and low splinter risk when sanded to 180–220 grit. Many buyers prefer this species over spruce or pine for sauna interiors thanks to comfortable surface temps.

5. Industrial and Commercial Uses

Pallets and Shipping Crates

Manufacturers pick hemlock for pallets, crates, and boxes thanks to light weight and reasonable strength-to-cost. Western hemlock is a major commercial species in the Pacific Northwest supply chain for construction lumber and fiber, as noted by the Alaska DCCED profile on Western Hemlock, supporting broad industrial demand.

Packaging Applications

Packaging plants use hemlock for dunnage, separators, and light crates where clean machining and low resin matter. Heat-treat for export stamps (ISPM 15) and select uniform thicknesses to streamline automation.

Timber Production

Timber mills convert hemlock into framing, panel stock, and pulp for paper products. Straight, tall logs help recover long boards, keeping pricing competitive across many markets.

6. Furniture and Woodworking Projects

Utility Furniture Components

Builders use hemlock for drawer runners, cabinet backs, shop furniture, and utility tables. If you need harder stock for wear areas, compare with yellow pine and adjust joinery for long-term service.

Shelving and Cabinetry

Shelving in closets and pantries works well with hemlock when supported every 16–24 inches to limit sag. Seal with clear coat or paint-grade primer and add a front edge band for stiffer, clean lines.

Crafts and Specialty Items

Crafters turn hemlock into moldings, toys, and decor pieces where weight savings help. Use sharp gouges, take light cuts, and sand to fine grits to avoid raised grain and rough surfaces.

7. Outdoor and Decking Applications

Fencing and Enclosures

Exterior use is possible for short-life or protected builds like garden fencing, animal pens, and privacy screens. Add a cap rail to shed water, keep posts off soil with hardware, and design for easy panel swaps.

Treatment Requirements

Hemlock lacks natural rot resistance, so use pressure-treated stock or apply a penetrating oil or exterior varnish. Recoat on a schedule and lift end-grain from wet surfaces to extend service life.

Budget-Friendly Exterior Projects

Budget builds like temporary decking, site barriers, or shed cladding can make sense with treated hemlock. For longer exposure, see options in this guide to the best wood for outdoor furniture and pick finishes that match local weather.

8. Comparing Hemlock Wood Varieties

Eastern vs Western Hemlock Wood

Eastern Hemlock shows light reddish-brown color and can splinter, while Western Hemlock runs slightly softer in grain and widely supplies long, straight boards. For a higher-elevation species that’s a bit heavier and harder, see the Mountain Hemlock profile for context on shared traits across Tsuga.

Canadian Hemlock Wood Properties

Canadian hemlock sold for interiors is typically straight-grained, low-odor, and easy to finish. It’s common in sauna kits, paneling, and trim work where a uniform look and low pitch are top priorities.

Choosing the Right Type

Match species to project goals: long framing runs favor Western Hemlock supply, while interior trim often leans Canadian sources; Eastern Hemlock remains a solid all-rounder for general lumber. Treat any exterior components and compare grades for the best balance of cost and strength.

| Feature | Canadian Hemlock | Western Hemlock | Eastern Hemlock |

|---|---|---|---|

| Typical Source | Canada | Pacific Northwest U.S. & B.C. | Eastern North America |

| Common Uses | Saunas, paneling, trim | Framing lumber, pulp | Construction, framing |

| Grain/Texture | Straight, coarse | Straight, softer grain | Straight/spiral, coarse |

| Appearance | Light reddish brown | Light brown | Light reddish brown |

| Durability | Non-durable; treat for exterior | Non-durable; treat for exterior | Non-durable; treat for exterior |

| Sensitivities | Possible mild skin irritation | Generally mild | Possible mild skin irritation |

FAQs about Hemlock Wood (Brief)

Is it durable? Not by default; use it indoors or protect it outside with treatment or quality finishes for longer life.

Where to use? Top picks include framing, interior trim, sauna interiors, crates, and utility furniture.

Any cautions? Wear gloves if you have skin sensitivity and pre-drill near edges to limit splits.

Related reads: Compare species like larch wood or evaluate construction wood grades for framing choices.

FAQs

What Are The Uses Of Hemlock Wood?

Hemlock Is Commonly Used For Framing, Siding, Interior Trim, Paneling, And Utility Lumber Because Of Its Straight Grain And Workability. It Accepts Paint And Stain Well, Making It Suitable For Furniture, Cabinetry, And Decorative Millwork When Properly Finished.

Is Hemlock Wood Good For Outdoor Projects?

Hemlock Can Be Used For Outdoor Projects But Is Not Naturally Very Decay-Resistant; It Performs Well For Covered Structures Like Porches Or Trim If Sealed And Maintained. For Ground Contact Or Exposed Outdoor Use, Pressure Treatment Or A More Durable Species Like Cedar Or Redwood Is Recommended.

How Does Hemlock Wood Compare To Other Types Of Wood?

Compared With Other Softwoods, Hemlock Is Similar To Spruce And Fir: Affordable, Stable, And Easy To Machine But Softer And Less Decay-Resistant Than Cedar Or Hardwoods. It Offers Good Dimensional Stability And A Straight Grain But Lacks The Natural Oils And Rot Resistance Of Species Like Cedar And Cypress.

What Is The Durability Of Hemlock Wood?

Hemlock Has Moderate Durability In Dry, Protected Environments But Is Not Highly Durable When Exposed To Moisture Over Time. Its Lifespan Depends On Exposure, Finish, And Maintenance; Treated Or Well-Sealed Hemlock Will Last Much Longer Outdoors.

Is Hemlock Wood Resistant To Pests And Rot?

Hemlock Is Not Particularly Resistant To Pests And Rot In Its Untreated State And Can Be Susceptible To Insect Attack And Fungal Decay. Kiln Drying, Preservative Treatments, And Proper Sealing Will Greatly Reduce These Risks For Exterior Or Ground-Contact Applications.