Hardest Wood in the World: Top 10 Woods Ranked by Janka Hardness

What is the hardest wood in the world? If you picture a tree that barely dents, think of woods with very high Janka scores. This post lists the top 10, led by Australian Buloke with a 5,060 lbf rating. You will find each wood’s score, common uses, and simple tips for picking strong wood for heavy wear.

Table of Contents

Curious about the hardest wood in the world? This guide explains what is the hardest wood in the world, how hardness is measured, and where the hardest wood in the world shines in real projects.

What Is the Hardest Wood in the World?

The Australian Buloke is the hardest wood in the world, recording a Janka hardness of 5,060 lbf, which far exceeds common hardwoods used in homes; this ranking is widely reported across trade sources like Top 10 hardest woods. If you’re asking “what is the hardest wood in the world,” the answer is Australian Buloke, and the hardest wood in the world is prized where extreme dent and wear resistance matter.

Australian Buloke – The Record Holder

This Australian ironwood grows dense, tight fibers that make it incredibly resistant to surface damage and abrasion. Builders choose it sparingly because the hardest wood in the world can be slow to machine and heavy to transport, yet it holds up in punishing settings.

Understanding Wood Hardness Measurement

Wood hardness is measured on the Janka scale, which quantifies the force required to press a steel ball halfway into the wood. The harder the wood, the more force it resists, and the hardest wood in the world leads the chart by a wide margin.

Understanding the Janka Hardness Scale

The Janka hardness test standardizes wood hardness in lbf or newtons, giving buyers an objective wear-resistance rating. Use this scale to compare the hardest wood in the world against common flooring and decking options.

How the Test Works

The Janka test drives a 0.444-inch steel ball into clear, conditioned wood until it’s embedded halfway, and the force reading reflects dent resistance.

Common industry definition

Labs test heartwood across the grain at roughly 12% moisture to keep results comparable between species. This lets you see just how hard the hardest wood in the world is relative to everyday species you might buy.

Interpreting Hardness Ratings

Higher lbf equals higher dent resistance, which helps floors, decks, and work surfaces stay smooth under impact. Keep in mind the hardest wood in the world can be tough on blades and bits, so carbide tooling and pre-drilling save time.

Context with Common Woods

Here’s a quick comparison so you can see how the hardest wood in the world stacks up next to everyday options used in projects. These values are typical averages; individual boards can vary with growth conditions.

| Wood Species | Approx. Janka (lbf) |

|---|---|

| Australian Buloke | 5,060 |

| Ipe (Brazilian Walnut) | 3,680 |

| Hard Maple | 1,450 |

| White Oak | 1,360 |

| Northern Red Oak | 1,290 |

| American Walnut | 1,010 |

| Teak | ~1,000 |

| Southern Yellow Pine | ~690 |

1. Australian Buloke – 5,060 lbf

Australian Buloke ranks as the hardest wood in the world with extreme density that shrugs off dents and abrasion. Carpenters cut slowly, use sharp carbide, and pre-drill because the hardest wood in the world resists fasteners and can blunt tools.

2. Schinopsis brasiliensis (Baraúna) – 4,800 lbf

This South American hardwood is known for its exceptional compressive strength and overall toughness. When properly seasoned, it offers good dimensional stability despite its extreme density.

Baraúna is strong and can handle heavy use. It works well in tough places like door thresholds, industrial floors, and other surfaces that get a lot of impact.

Ranked as one of the hardest woods in the world, it machines well with sharp tools. It can hold sharp edges, making it good for both structural and precise uses.

3. Schinopsis balansae (Quebracho) – 4,570 lbf

Quebracho is known locally as “axe-breaker,” which says a lot about its tough surface and mass. It sits close to the hardest wood in the world tier and serves well in posts, bridge timbers, and wear blocks.

Kiln-Dried Red Quebracho Turning Blank (8×8×2 in)

- Kiln-dried Red Quebracho platter blank

- S4S surfaced on four sides for easier setup

- Approx. 8 in × 8 in × 2 in size for platter or bowl turning

- Very dense and hard wood for durable finished pieces

- Red Quebracho (Schinopsis spp.) with South American origin

4. Guayacan (Lignum vitae) – 4,500 lbf

Lignum vitae combines extreme hardness with a high concentration of natural, self-lubricating oils. These oils greatly lower friction. This helps the wood work well in moving parts like bearings and propeller shaft sleeves without extra lubrication.

Because of this unique combination of hardness and lubrication, it has long been valued in mechanical and industrial applications where heat and wear are constant concerns.

Lignum vitae is one of the hardest woods in the world. It also resists decay and moisture very well. This makes it great for marine hardware, underwater parts, and special tools. These items need to last in tough, wet conditions for a long time.

Woodcraft Lignum Vitae Turning Blank (2x2x12)

- Genuine Lignum Vitae (Guaiacum officinale) hardwood

- One solid piece sized 2 x 2 x 12 inches for turning and carving

- Known as one of the hardest and heaviest woods for durable parts

- Fine texture with interlocked grain and a naturally oily feel

- Polishes to a great finish and resists insect attack for long-lasting projects

5. Gidgee – 4,270 lbf

Gidgee from Australia is an extremely dense and heavy hardwood, known for its dark brown to near-black color and excellent dimensional stability once properly seasoned.

Its interlocked grain and natural oils make it highly resistant to moisture movement, wear, and impact, allowing it to perform reliably in harsh or demanding conditions.

Because it is very hard and tough on tools, craftspeople typically use Gidgee in small, high-stress components where durability is critical rather than in large decorative pieces.

Common applications include knife scales, heavy-duty mallets, and wear strips exposed to constant friction, where Gidgee’s exceptional hardness and longevity truly stand out.

6. Snakewood – 3,800 lbf

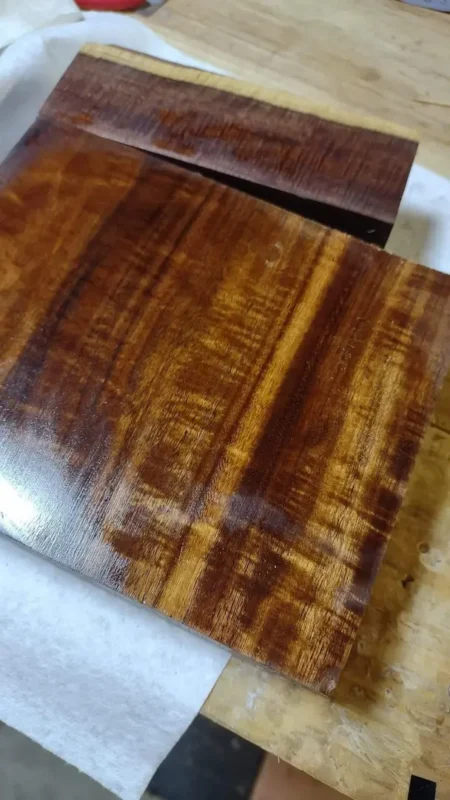

Distinctive Grain Patterns

Snakewood shows a dramatic freckled figure that looks like scales, making small pieces visually stunning. Many buyers rank it among the hardest wood in the world picks for inlays, bows, and high-end accents.

Rarity and Exotic Appeal

The supply is limited, pieces are short, and cracks can appear if drying isn’t careful, so selection and acclimation are key for this rare material. For deep info on sourcing and care, see our Snakewood guide covering grading, work tips, and uses among the hardest wood in the world species.

Snakewood Pen Blank 3/4 x 3/4 x 5 (1 Pc)

- Striking snakeskin-like black markings for a premium look

- Tight grain and rich reddish/orange tones

- Machines and turns well for pen blanks and small projects

- Polishes to a smooth, high-gloss finish

- Natural wood—each piece varies and size may differ slightly

7. Verawood – 3,710 lbf

Natural Oil Content

Verawood contains abundant natural oils that shed water and help resist decay, so wipe surfaces with solvent before gluing for a strong bond. It sits near the hardest wood in the world class and often polishes to a glassy sheen.

Musical Instrument Applications

Makers use Verawood for nuts and saddles, shaper jigs, and select wind instrument parts where stability matters. Its place beside the hardest wood in the world options reflects its durability and crisp attack in small components.

Outanaya Verawood Scalp Massage Comb

- Retro carved verawood/sandalwood comb for hair and beard grooming

- Massages your scalp while you comb to relax and smooth hair

- Designed to help ease itchiness during daily scalp care

- Premium wood material for durable long-lasting use

- Compact size about 12.3 x 4.7 cm for easy home or travel use

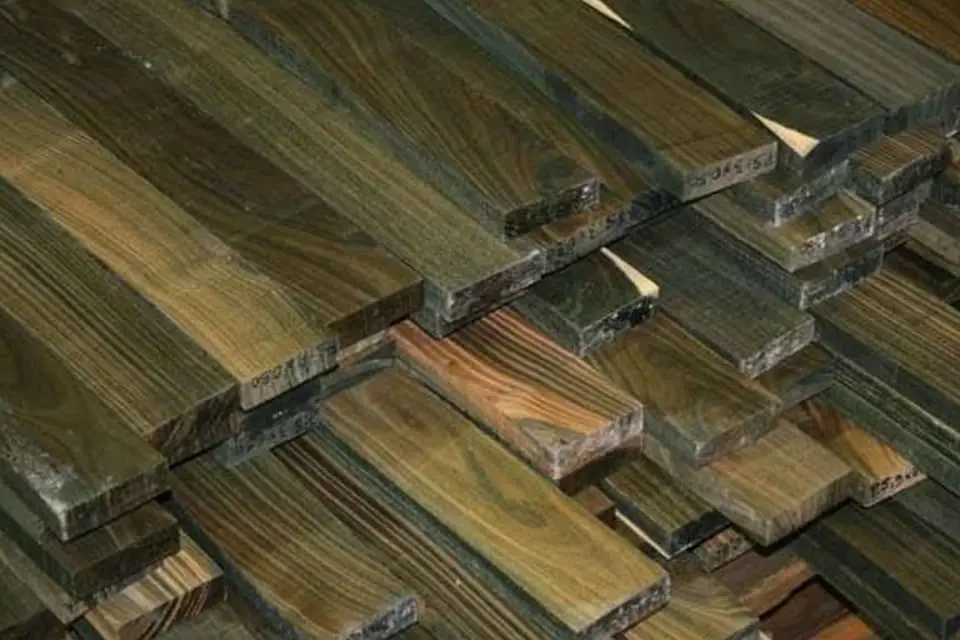

8. Camelthorn – 3,680 lbf

This Southern African hardwood is known for its very high density, excellent weather resistance, and strong dimensional stability when dried slowly and correctly.

Thanks to its toughness and durability, Camelthorn ranks among the hardest woods in the world and is well-suited for demanding, high-wear applications.

It is often used for strong fence posts that need to withstand tough outdoor conditions. It is also used for mallets and finely detailed items where strength and precision matter.

Namibfire Kameeldoring Camel Thorn BBQ Wood Splits (20 lb)

- Dense Camel Thorn hardwood burns hotter and longer for steady coals

- 20 lb pack of ~11-inch splits sized for grills smokers and outdoor baking

- Bold smoky flavor and aroma similar to mesquite

- Ideal for smoking or grilling meats seafood and vegetables

- Sustainably harvested in Namibia and hand-sorted/packed in South Africa

9. African Blackwood – 3,670 lbf

Instrument Making Excellence

African Blackwood is the gold standard for clarinets, oboes, and bagpipe chanters thanks to its close grain and dimensional stability. Luthiers value it among the hardest wood in the world species for precise boring and clean threads.

Tonal Qualities

The dense body yields quick attack and clear articulation, while low porosity reduces moisture uptake during long sessions. Players seeking alternatives sometimes compare it with ebony wood, though the hardest wood in the world list places Blackwood in a unique category for wind instruments.

Oedema Black Ebony Knife Scale Blanks (2-Pack)

- Black ebony wood with high hardness and fine texture

- Sized about 4.72 x 1.57 x 0.39 inches per piece

- Bold natural grain for a premium look

- Unfinished blanks—easy to DIY, carve, stain, or paint

- Great for knife handles, woodworking projects, boxes, and crafts

10. Grey Ironbark – 3,664 lbf

Construction Applications

Grey Ironbark handles heavy loads in bridge decking, sleepers, and structural members where impact and abrasion are constant. It’s a frequent substitute when projects call for the hardest wood in the world tier strength with reliable supply in Australia.

Australian Heritage Wood

This eucalypt has a long track record in harsh climates and needs proper seasoning to limit internal stresses. Builders pick it from the hardest wood in the world category for wharf piles, posts, and exterior framing.

Doc of All Trades Red Ironbark Knife Scales

- Red Ironbark wood knife scales for custom handles

- Approx. 5 in × 1.5 in × 3/8 in sizing

- Listed hardness around ~3200 for durability

- Workability rated 9/10 (hard but workable)

- Colorfastness rated 3/4 with grain/figure that varies

Properties and Applications of Ultra-Hard Woods

Across the hardest wood in the world lineup, you’ll see exceptional density, high wear resistance, and longer service life under foot traffic and impact. Plan for slower machining, higher tool costs, and thoughtful design that respects weight and movement.

Industrial and Marine Uses

Hard, oily species like Lignum vitae and Verawood excel in bearings, bushings, sheaves, and deadeyes where lubrication and wear resistance are prized; see this overview of the strongest wood for context. Many crews still spec these woods from the hardest wood in the world group for applications that punish softer timbers.

- Bearings and thrust washers for wet environments

- Heavy-use decking on docks and piers

- Wear strips, skid plates, and machine beds

- Lock gates, fenders, and bollards in ports

Flooring and Decking

For busy spaces, species near the hardest wood in the world tier resist dents and keep a smooth surface longer; acclimate well and pre-drill.

Tool Handles and Specialty Items

Dense woods make shock-resistant mallets, chisels, plane soles, and wear parts; Gidgee, Buloke, and Camelthorn stand out. For bright handle color with good hardness, consider Osage orange as a practical complement to the hardest wood in the world picks

Decorative and Artistic Applications

Small, high-density blanks turn into pens and knobs with crisp details and a deep polish. Turners often pair Snakewood or African Blackwood with colorful species like cocobolo to contrast the hardest wood in the world hues and textures.

Factors That Influence Wood Hardness

Several variables push a species higher or lower on the chart that ranks the hardest woods in the world. Knowing these helps you pick boards that behave predictably.

Species Genetics

Genetic traits set fiber density, cell structure, and extractive content that drive base hardness. That’s why the hardest wood in the world group is dominated by slow-growing species with tight grain.

Growth Conditions

Soil, rainfall, and growth rate affect ring width and latewood fraction, which influence hardness. Trees from drier or harsher sites often produce wood closer to the hardest wood in the world range.

Grain Orientation Effects

Hardness varies with test direction: across the grain (side hardness) is what the Janka scale reports, while end-grain hardness is much higher. Quartered boards can feel a bit different underfoot than flatsawn, even within the hardest wood in the world set.

Moisture Content Impact

At higher moisture, hardness drops; at near 12% MC, readings are most comparable between species. Keep your project wood at room conditions before working, especially with the hardest wood in the world species that move less but still react to climate.

FAQs

What Is The Hardest Wood In The World?

Australian Buloke Is Commonly Cited As The Hardest Wood Based On Janka Hardness Tests (Often Reported Around 5,000+ Lbf). Other Extremely Hard Species Include Lignum Vitae And Quebracho, But Exact Rankings Can Vary With Sample, Moisture Content, And Test Method.

How Is Wood Hardness Measured?

Wood Hardness Is Typically Measured Using The Janka Hardness Test, Which Records The Force Required To Embed A 0.444-Inch Steel Ball Halfway Into The Wood. Results Are Given In Pounds-Force (Lbf) Or Newtons And Indicate Resistance To Denting And Wear, Not Overall Strength Or Durability.

What Are The Uses Of The Hardest Woods?

The Hardest Woods Are Used Where High Wear Resistance Is Needed: Premium Flooring, Heavy-Duty Tool Handles, Bearings, Turned Objects, And Specialty Millwork. They Perform Well Under Abrasion But Can Be Difficult To Machine, Nail, Or Glue, So They’re Best For Applications That Justify Extra Effort And Cost.

Are The Hardest Woods Also The Most Durable?

Not Necessarily. Hardness Measures Resistance To Denting, While Durability Refers To Rot, Insect Resistance, And Long-Term Stability. Some Very Hard Woods Can Be Brittle Or Susceptible To Decay, Whereas Moderately Hard Species Like Teak Offer Excellent Natural Durability Against Moisture And Pests.

How Does The Hardness Of Wood Affect Its Price?

Hardness Can Raise Price Because Very Hard Species Are Often Rarer, Harder To Mill, And In Higher Demand For Specialty Uses Like Flooring. However, Price Also Depends On Availability, Aesthetic Appeal, Certification (Sustainability), And Workability—so Hardness Is Only One Of Several Cost Drivers.